地球上で最大の生態系である海は、豊富な生物資源を保有しています。中でも海藻は、多糖類、食物繊維、ミネラル、抗酸化物質といった特有の栄養素や生理活性化合物を豊富に含み、「海の野菜」や「未来の食糧」とも呼ばれています。乾燥海藻の栄養価と機能性を最大限に引き出すには、従来の粗加工だけではもはや不十分です。食品、医薬品、化粧品といった現代のハイエンド産業では、より微細な加工が求められています。 超微粉砕 乾燥海藻の(微粉化) そのため、複数の分野で注目を集める重要な技術として浮上しています。

応用分野:微粒化海藻粉末の無限の可能性

超微粉砕技術によって処理された乾燥海藻粉末の粒子径は、ミクロンレベル、さらにはサブミクロンレベルに達します。これにより比表面積が大幅に増加し、次のような重要な応用価値がもたらされます。

機能性食品と栄養補助食品

超微粉砕 海藻細胞壁を効果的に分解し、海藻多糖類、ヨウ素、カルシウムなどの栄養素の放出と生物学的利用能を大幅に向上させます。これにより、人体への吸収が容易になります。微粒化海藻パウダーは、栄養補助食品の高品質な原料として、またヨーグルト、飲料、焼き菓子などの製品に添加することができます。

食品の増粘と乳化

極めて微細な海藻粉末、特にアルギン酸とカラギーナンは、優れた吸水性とゲル形成能を有しています。天然の安定剤、増粘剤、乳化剤として機能し、食品の食感と口当たりを改善します。

医薬品・化粧品

海藻に含まれる有効成分(フコイダンなど)には、抗酸化作用と抗炎症作用があります。超微粒子パウダーは均一に分散し、肌への吸収性が高いため、マスクやローション、あるいは生理活性薬剤のキャリアとして最適です。

現代農業(海洋ナノ肥料)

微粒子化された海藻は、効率的な海洋生物肥料や土壌改良剤として機能し、植物の成長を促進し、作物の品質を向上させます。

課題:乾燥海藻の超微粉砕における技術的困難

潜在能力があるにもかかわらず、乾燥海藻の工業規模の超微粉砕には、3 つの大きな課題があります。

- 素材特性 - 「強靭、粘着性、柔軟性」:

乾燥海藻は繊維、多糖類、微量の油分を含み、強靭性、粘着性、弾力性に優れています。高速衝撃粉砕では、原料が内壁に付着したり、ふるいに詰まったりする傾向があり、生産効率が低下し、所望の細かさを得ることが困難です。 - 熱感受性と栄養素の保持:

海藻に含まれる多くの生理活性成分(ビタミン、多糖類など)は熱に敏感です。従来の高速機械粉砕では、大きな摩擦熱が発生し、酸化や熱劣化を引き起こし、製品の栄養価と風味を低下させる可能性があります。 - 純度と細かさのジレンマ:

超微粒子サイズ(例:100~300 メッシュまたはそれより細かい)を実現するには、高い粉砕強度が必要であり、これにより機器の摩耗が加速され、最終製品に金属汚染が発生するリスクが高まります。

革新的なソリューション:低温・高効率超微粉砕技術

これらの課題を克服するために、現代の粉体工学では、海藻の特性に合わせた一連の革新的なソリューションを開発しました。

1. ジェットミル

原理: 高圧空気流を利用して粒子同士の衝突を起こして粉砕します。

特徴: 熱によるダメージがなく、金属汚染もなく、粉末活性が高い。

用途: 高価値の海藻粉末や精製多糖類の加工に最適です。

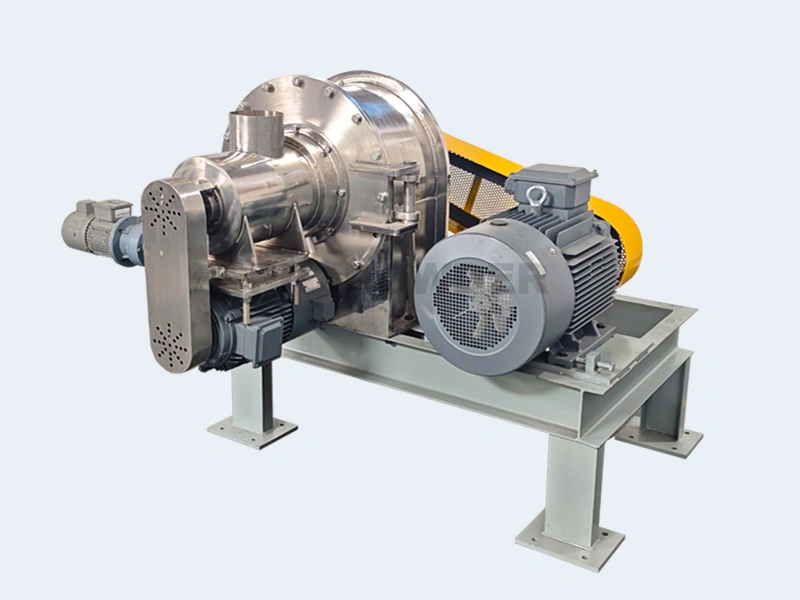

2. 空気分級ミル(ACM) そして インパクトミル

原理: 衝撃粉砕と動的空気分級を組み合わせます。海藻粒子は高速ハンマーまたはブレードで粉砕され、分級ホイールは精密な空気力学に基づいて微細粒子を分離し、粗い粒子は粉砕ゾーンに戻します。

利点: 粒度分布が狭いため、連続的かつ効率的な粉砕が可能です。気流と分級速度を調整することで、製品の粒度を精密に制御できます。

3. 極低温粉砕技術

原理: 粉砕中に液体窒素または冷気を導入して、材料をガラス転移温度以下に急速に冷却します。

利点: 低温下では、海藻は粘り気と粘り気を失い、脆くなって粉砕されやすくなります。これにより粉砕効率が大幅に向上し、熱に弱い栄養素が保持され、酸化や変色を防ぐことができるため、高級海藻パウダーの製造に最適な技術となっています。

4. 不活性ガス保護と付着防止設計

窒素などの不活性ガスを粉砕室に導入することで、加工中の酸化を効果的に防止します。さらに、内面は滑らかな仕上げと最適化された空気の流れを備え、重要な部品にはセラミックなどの付着防止材をコーティングすることも可能です。これらの対策により、金属汚染を最小限に抑えながら、固着や目詰まりの問題を解決します。

結論

乾燥海藻の超微粉砕は、海洋資源の付加価値を高め、機能性食品や新素材の開発に貢献します。空気分級ミル、極低温システム、そして汚染制御を組み合わせることで、粉末業界は海藻の「硬さ、粘り気、柔軟性」といった特性を克服することができます。その結果、安定的かつ効率的なプロセスが実現し、高い生理活性、純度、そして吸収性に優れた海藻粉末が生産されます。これらのイノベーションは、消費者と産業界の双方にとって高品質な海洋健康製品を提供します。