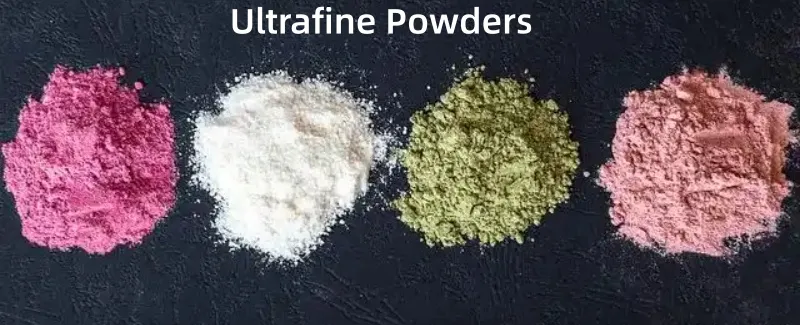

Bubuk ultrahalusIstilah "s" merujuk pada serbuk dengan ukuran partikel yang sangat kecil. Ukurannya berkisar dari beberapa nanometer hingga beberapa puluh mikrometer. Meskipun tidak ada definisi yang pasti, istilah ini digunakan secara luas di berbagai industri. Istilah ini sering dikategorikan berdasarkan aplikasi dan metode penyiapan. Klasifikasi yang umum adalah sebagai berikut:

Serbuk halus: ukuran partikel antara 10 dan 45 μm.

Bubuk mikron: ukuran partikel antara 1 dan 10 μm.

Bubuk submikron: ukuran partikel antara 0,1 dan 1 μm.

Nanopowder: ukuran partikel antara 0,001 dan 0,1 μm, yaitu 1 hingga 100 nm.

Seiring mengecilnya ukuran partikel, sifat-sifat serbuk ultrahalus berubah drastis. Ketika skala partikel mencapai tingkat submikron atau nanometer, susunan atom permukaan dan struktur kristalnya berubah secara signifikan. Perubahan-perubahan ini menyebabkan efek permukaan, efek ukuran, efek kuantum, dan efek terowongan kuantum. Oleh karena itu, serbuk ultrahalus menunjukkan sifat fisik, kimia, dan antarmuka yang unik dalam aplikasi khusus.

Namun, bubuk ultrafine juga menghadapi tantangan. Luas permukaannya yang besar dan energi permukaannya yang tinggi membuatnya tidak stabil. Bubuk ultrafine cenderung menggumpal untuk mengurangi energi permukaan. Penggumpalan ini dapat menyebabkan partikel menjadi kasar dan mengurangi kinerja. Hal ini juga mempersulit proses penggilingan lebih lanjut.

Mekanis Penggilingan Ultrahalus Dampak

Prinsip dan Jenis

Penggilingan ultrafine impak mekanis menggunakan elemen impak bergerak berkecepatan tinggi untuk memberikan gaya yang kuat pada material. Proses penggilingan terjadi melalui tumbukan partikel-partikel dan tumbukan antara partikel dan komponen penggiling.

Mekanisme kerja utamanya melibatkan energi yang dihasilkan oleh beberapa tumbukan. Energi ini jauh lebih tinggi daripada energi aktual yang dibutuhkan untuk penghancuran. Kecepatan tumbukan yang lebih tinggi dan waktu kontak yang lebih singkat meningkatkan energi yang diberikan per satuan waktu. Hal ini membuat material lebih mudah digiling.

Di celah antara stator dan rotor, material mengalami gaya geser. Material tersebut kemudian memantul ke dalam ruang dan bertabrakan dengan partikel lain yang bergerak cepat. Hal ini menjaga proses penggilingan tetap berjalan.

Medan turbulen berkecepatan tinggi yang kuat terbentuk antara lapisan stator dan elemen impak rotor. Variasi tekanan di medan ini menciptakan tegangan bolak-balik yang menghancurkan material. Oleh karena itu, efek penggilingan bergantung pada kecepatan rotor, celah stator-rotor, dan sifat material.

Keunggulan Teknis Jdan Mills

Prinsip Dasar Jet Milling

Jet mill menggunakan aliran gas berkecepatan tinggi atau uap super panas untuk menciptakan medan turbulen yang kuat. Penggilingan terjadi melalui tumbukan partikel-partikel, tumbukan dan geseran yang disebabkan oleh aliran udara, serta gesekan dengan dinding ruang.

Jet mill digunakan secara luas di berbagai industri. Tersedia dalam berbagai jenis, seperti flat mill, circulation-tube mill, opposite jet mill, dan impact jet mill. Penggilingan terutama terjadi di dekat nozel. Frekuensi tumbukan antar partikel jauh lebih tinggi daripada frekuensi tumbukan antara partikel dan dinding. Oleh karena itu, tumbukan antar partikel mendominasi proses penggilingan.

Tipe Datar Pabrik Jet

Gas bertekanan tinggi memasuki ruang distribusi udara, yang terhubung ke ruang penggilingan. Ketika gas melewati nosel, kecepatannya mencapai ratusan atau bahkan ribuan meter per detik. Saluran masuk gas dan tabung jet berpotongan pada sudut tertentu, membentuk pusaran berputar. Hal ini mendorong tumbukan, gesekan, dan geseran partikel. Gaya sentrifugal memungkinkan klasifikasi partikel yang akurat.

Desain Jet dan Fluidized Bed yang Berlawanan

Penggilingan jet berlawanan, juga disebut penggilingan jet berlawanan, menggunakan dua aliran gas yang berlawanan. Partikel-partikel tersebut bertabrakan secara langsung sejak awal. Desain ini mengurangi abrasi dan kontaminasi dinding. Penggilingan ini cocok untuk material keras dan produksi bubuk ultrafine. Namun, strukturnya kompleks dan konsumsi energinya tinggi.

Mesin giling jet berlawanan fluida menggabungkan prinsip jet berlawanan dengan aliran ekspansi fluida. Mesin ini membentuk sistem penggilingan gas-padat yang efisien. Mesin giling jet berlawanan fluida seri EPIC Powder MOQ merupakan model representatif. Proses kerjanya adalah sebagai berikut. Material memasuki hopper umpan melalui katup. Kemudian, material tersebut disalurkan ke ruang penggilingan oleh pengumpan ulir atau gravitasi. Udara bertekanan tinggi diinjeksikan melalui nosel berlawanan. Partikel-partikel tersebut terfluidisasi dan bertumbukan dengan energi tinggi untuk mencapai penggilingan ultrahalus.

Kesimpulan

Serbuk ultrahalus, yang ditentukan oleh rentang ukurannya yang spesifik, menunjukkan efek permukaan dan ukuran yang kuat. Serbuk ini memiliki potensi besar dalam industri modern. Namun, ketidakstabilan dan penggumpalannya menimbulkan tantangan.

Penggilingan impak mekanis dan penggilingan jet, termasuk tipe datar, jet berlawanan arah, dan unggun terfluidisasi, membantu mengatasi masalah ini. Mesin-mesin ini menggunakan impak berkecepatan tinggi, tumbukan partikel, dan turbulensi yang kuat untuk mencapai penggilingan dan klasifikasi yang efisien dan presisi.

Teknologi bubuk masa depan akan berfokus pada dispersi yang stabil, penggilingan ultra-halus berenergi rendah, dan perlindungan lingkungan. Kemajuan ini akan semakin meningkatkan sifat unik bubuk ultra-halus dan mendukung kemajuan material canggih dan industri berteknologi tinggi.