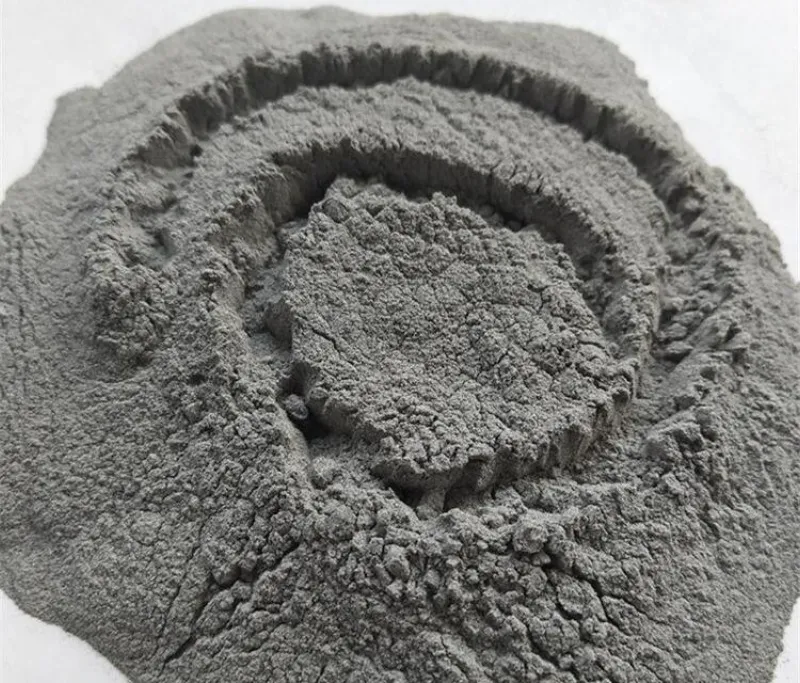

Abu terbang ultrahalus, produk sampingan dari pembangkit listrik tenaga batu bara, menunjukkan multifungsi unik dalam bahan bangunan setelah pemrosesan super halusPenggunaannya tidak hanya meningkatkan kinerja material tetapi juga membawa manfaat lingkungan dan ekonomi yang signifikan.

Peran Abu Terbang Ultrahalus dalam Bahan Bangunan

Efek Pozzolanik: Zat aktif dalam abu terbang super halus bereaksi dengan bahan alkali untuk membentuk produk hidrolik, meningkatkan kekuatan beton.

Efek Morfologi: Bentuk partikel dan sifat permukaan abu terbang superhalus meningkatkan struktur pori dan kekompakan beton.

Efek Mikroagregat: Abu terbang yang sangat halus mengisi rongga dan pori-pori kapiler dalam pasta semen, meningkatkan daya tahan beton.

Efek Antarmuka: Bereaksi dengan produk hidrasi semen, meningkatkan zona transisi antarmuka dan kekuatan ikatan.

Keunggulan Performa dalam Material Bangunan

Peningkatan Kekuatan:Penambahan abu terbang ultrahalus secara signifikan meningkatkan kekuatan tekan dan lentur beton.

Peningkatan Kemampuan Kerja: Abu terbang super halus meningkatkan kemampuan kerja beton segar, mengurangi pendarahan dan pemisahan.

Peningkatan Daya Tahan: Dengan meningkatkan kekompakan, abu terbang superhalus meningkatkan daya tahan dan kedap air beton.

Pengurangan Biaya:Abu terbang super halus menggantikan sebagian semen, sehingga menurunkan biaya produksi.

Manfaat Lingkungan dan Ekonomi

Daur Ulang Sumber Daya:Penggunaan abu terbang ultrahalus mengurangi eksploitasi sumber daya alam dan mendorong daur ulang limbah industri.

Pengurangan Emisi:Penggunaannya mengurangi emisi CO₂ dari produksi semen, memenuhi persyaratan perlindungan lingkungan.

Manfaat Ekonomi:Produksi dan penerapan abu terbang ultrahalus menghasilkan nilai ekonomi sekaligus menghemat sumber daya bagi masyarakat.

Proses Produksi Abu Terbang Superhalus

Koleksi: Abu terbang mentah diambil dari silo penyimpanan pembangkit listrik.

Menggiling:Abu terbang mentah dimasukkan ke dalam peralatan penggilingan (pabrik bola atau jenis lainnya) untuk penggilingan halus hingga kehalusan yang dibutuhkan.

KlasifikasiAbu terbang yang telah digiling melewati pengklasifikasi untuk memisahkan bubuk halus dari bubuk kasar. Partikel kasar dikembalikan untuk digiling lebih lanjut, sementara bubuk halus melanjutkan ke tahap berikutnya.

Koleksi: Abu terbang yang sangat halus dikumpulkan oleh pengumpul debu, mencegah emisi dan memastikan lingkungan kerja yang bersih.

Penyimpanan: Abu terbang superhalus yang terkumpul disimpan dalam silo khusus untuk penggunaan selanjutnya.

Pengemasan dan Transportasi: Abu terbang super halus dapat dikemas dan diangkut dengan kendaraan atau sarana lain ke lokasi aplikasi.

Pada beberapa lini produksi, sistem penggilingan sirkuit tertutup Digunakan untuk meningkatkan efisiensi dan kualitas produk. Sistem ini biasanya mencakup mesin penggiling ultrafine, pengklasifikasi, dan pengumpul debu. Kontrol proses yang akurat memastikan kualitas produk yang stabil.

Desain produksi abu terbang ultrafine memerlukan pemilihan spesifikasi pabrik, pelapis, dan media penggilingan yang sesuai untuk mencapai output tinggi, konsumsi energi rendah, dan hasil penggilingan halus. Pengklasifikasi memainkan peran kunci, karena efisiensi pemisahan secara langsung memengaruhi kapasitas sistem. Kinerja pengumpulan debu juga harus dipertimbangkan untuk mengendalikan emisi dalam batas standar.

Kontrol kualitas yang ketat mencakup kehalusan, luas permukaan spesifik, komposisi kimia, dan distribusi partikel untuk memastikan kinerja yang aman dan andal dalam aplikasi.

Bubuk epik

Multifungsi abu terbang ultrafine dalam material bangunan tidak hanya tercermin dalam peningkatan kinerja tetapi juga kontribusinya terhadap lingkungan dan ekonomi. Dengan penelitian dan kemajuan teknologi yang berkelanjutan, prospek penerapan abu terbang superfine akan semakin luas.

Dengan lebih dari 20 tahun pengalaman dalam teknologi bubuk super halus, EPIC POWDER menyediakan peralatan penggilingan super halus dan sistem klasifikasi canggih untuk pemrosesan abu terbang. Dengan memastikan kontrol ukuran partikel yang presisi, efisiensi tinggi, dan kualitas produk yang stabil, EPIC POWDER membantu mengubah produk sampingan industri menjadi solusi material bangunan bernilai tinggi, yang mendorong pembangunan berkelanjutan dan pertumbuhan ekonomi.