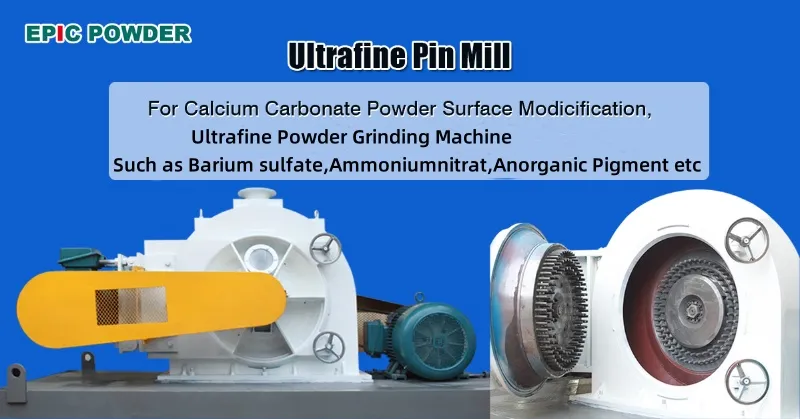

Pabrik penggilingan ultrahalus adalah peralatan khusus yang dirancang untuk memecah bahan menjadi ukuran partikel yang sangat halus, biasanya di bawah 10 mikron.

Tidak seperti penggiling dampak mekanis tradisional, penggiling ultra halus mencapai kehalusan mikron atau bahkan submikron melalui aliran udara berkecepatan tinggi, gaya sentrifugal, dan klasifikasi yang tepat.

Ini pabrik digunakan secara luas dalam industri seperti mineral, keramik, kimia, farmasi, pigmen, dan bahan baterai, di mana kemurnian produk dan pengendalian ukuran partikel sangat penting.

Prinsip Kerja Mesin Penggiling Ultra Halus

Meskipun prinsip kerja bervariasi di antara berbagai jenis penggilingan, konsep dasarnya tetap sama — mengurangi ukuran partikel melalui masukan energi dan melakukan klasifikasi yang tepat.

Pemberian Pakan dan Pra-Klasifikasi

Bahan baku pertama-tama dimasukkan ke dalam ruang penggilingan.

Sistem dapat mencakup pra-pengklasifikasi untuk memisahkan partikel kasar, mencegah kelebihan beban dan meningkatkan efisiensi.

Zona Penggilingan

Di zona penggilingan, material dikenakan gaya mekanis, pneumatik, atau sentrifugal yang kuat.

Jenis yang umum meliputi:

- Pabrik Jet: Menggunakan udara bertekanan berkecepatan tinggi untuk membuat partikel saling bertabrakan, sehingga menghasilkan penggilingan sangat halus bebas kontaminasi.

- Udara Penggolong Pabrik: Memanfaatkan dampak kecepatan tinggi dari cakram penggiling yang dikombinasikan dengan gaya sentrifugal; partikel bertabrakan dengan cincin penggiling dan hancur.

- Sistem Ball Mill + Klasifikasi: Menggabungkan penggilingan mekanis tradisional dengan klasifikasi udara untuk mengontrol distribusi ukuran partikel.

Tujuannya adalah untuk mencapai kehalusan yang diinginkan sambil menghindari panas berlebih atau kontaminasi.

Klasifikasi dan Koleksi

Setelah digiling, material melewati pengklasifikasi udara terpadu.

Bubuk halus dikumpulkan, sementara partikel kasar dikembalikan ke zona penggilingan untuk penggilingan lebih lanjut.

Proses loop tertutup ini memastikan distribusi ukuran partikel yang stabil dan kualitas produk yang konsisten.

Fitur Utama Mesin Penggilingan Ultra Halus

Ukuran partikel yang dikontrol secara tepat dan distribusi yang sempit

Operasi bebas kontaminasi, ideal untuk bahan dengan kemurnian tinggi

Pembangkitan panas rendah, cocok untuk bahan yang sensitif terhadap panas

Efisiensi energi tinggi dan konsumsi daya berkurang

Operasi otomatis dan kinerja stabil

Aplikasi Industri

Berkat kemampuannya menghasilkan bubuk dengan kemurnian tinggi, seragam, dan sangat halus, pabrik ini sangat diperlukan di banyak industri teknologi tinggi dan tradisional.

Mineral Nonlogam dan Bahan Bangunan

Aplikasi: Kalsium karbonat, bedak, kuarsa, kaolin, klinker semen, gipsum

Kegunaan:

- Meningkatkan kinerja pengisi dalam plastik, pelapis, dan cat

- Meningkatkan kekuatan semen dan beton serta kehalusan permukaan

Kehalusan Khas: D97 = 2–10 µm

Bahan Kimia dan Pigmen

Aplikasi: Titanium dioksida, oksida besi, pigmen keramik, pengisi

Kegunaan:

- Meningkatkan kekuatan warna dan daya sembunyi

- Meningkatkan dispersi dalam pelapis dan tinta

Keuntungan: Distribusi ukuran partikel yang sempit memastikan kualitas produk yang stabil

Farmasi dan Makanan

Aplikasi: Bahan aktif farmasi (API), eksipien, ekstrak herbal, susu bubuk, perasa

Kegunaan:

- Meningkatkan bioavailabilitas melalui mikronisasi

- Meningkatkan kelarutan dan rasa di mulut dalam aplikasi makanan

Kepatuhan: Terbuat dari baja tahan karat, mudah dibersihkan, dan sesuai dengan standar GMP

Bahan Energi Baru

Aplikasi:

- Bahan anoda baterai litium (grafit alami/buatan)

- Prekursor katoda (LFP, NCM)

- Bubuk silikon untuk fotovoltaik

Kegunaan: - Meningkatkan luas permukaan dan meningkatkan kinerja elektrokimia

- Mencapai D50 < 5 µm dengan kandungan pengotor yang sangat rendah

Manfaat Utama: Kemurnian tinggi dan konsumsi energi rendah

Perlindungan Lingkungan dan Daur Ulang Sumber Daya

Aplikasi: Abu terbang, terak, tailing, limbah padat industri

Kegunaan:

- Mengaktifkan material untuk semen ramah lingkungan

- Memulihkan bubuk halus yang berharga dari aliran limbah

Keuntungan: Mendukung daur ulang sumber daya dan ekonomi sirkular

Keuntungan Penggilingan Ultrahalus

| Fitur | Keuntungan |

|---|---|

| Tanpa Media Penggilingan | Mencegah kontaminasi (dibandingkan dengan ball mill) |

| Pembangkitan Panas Rendah | Cocok untuk bahan yang sensitif terhadap panas |

| Efisiensi Energi | Konsumsi energi hingga 30% lebih rendah dibandingkan pabrik tradisional |

| Desain Kompak | Jejak kecil, mudah diintegrasikan ke dalam lini produksi |

| Kontrol Otomatis | Pemantauan ukuran partikel dan keluaran secara real-time |

Mengapa Memilih BUBUK EPIK?

EPIC POWDER mengkhususkan diri dalam sistem penggilingan sangat halus, klasifikasi, dan modifikasi permukaan dan memiliki lebih dari 20 tahun pengalaman industri.

Perusahaan ini menyediakan solusi terpadu untuk kalsium karbonat, bubuk silikon, bahan baterai lithium, keramik, dan bubuk kimia.

Keunggulan kami meliputi:

- Desain sistem yang disesuaikan

- Kombinasi peralatan yang fleksibel (jet mill, ball mill, classifier, dll.)

- Komponen keramik kemurnian tinggi opsional

- Dukungan teknis global dan bantuan jarak jauh

Memilih EPIC POWDER berarti memperoleh solusi pemrosesan bubuk yang berpresisi tinggi, stabil, dan hemat biaya.

Terima kasih sudah membaca. Semoga artikel saya bermanfaat. Silakan tinggalkan komentar di bawah. Anda juga bisa menghubungi perwakilan pelanggan Zelda online untuk pertanyaan lebih lanjut.

— Diposting oleh Emily Chen