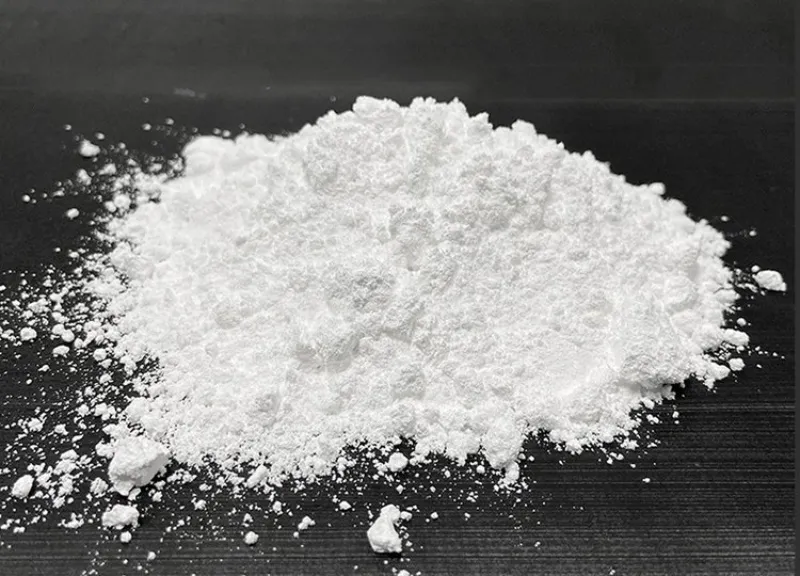

Alumina powder, that is, aluminum oxide (Al₂O₃) powder. Its excellent physical and chemical properties make it an irreplaceable choice in abrasive and polishing processes. It boasts high hardness (9 on the Mohs scale, second only to a few materials like diamond). It also offers excellent wear resistance and stable chemical properties. It resists acids, alkalis, and oxidation even at high temperatures. Its particle size can be precisely controlled. These advantages make it suitable for every stage of processing — from coarse grinding to ultra-precision polishing. It is widely used in a variety of industries, including metals, ceramics, glass, and semiconductors.

Application in the Abrasive Field

Abrasives are materials used for grinding, lapping, and polishing. They remove surface materials mechanically to improve shape and surface finish. Because of its overall superior performance, alumina powder has become one of the most common abrasives.

It is mainly used as bonded abrasives, coated abrasives, and loose abrasives.

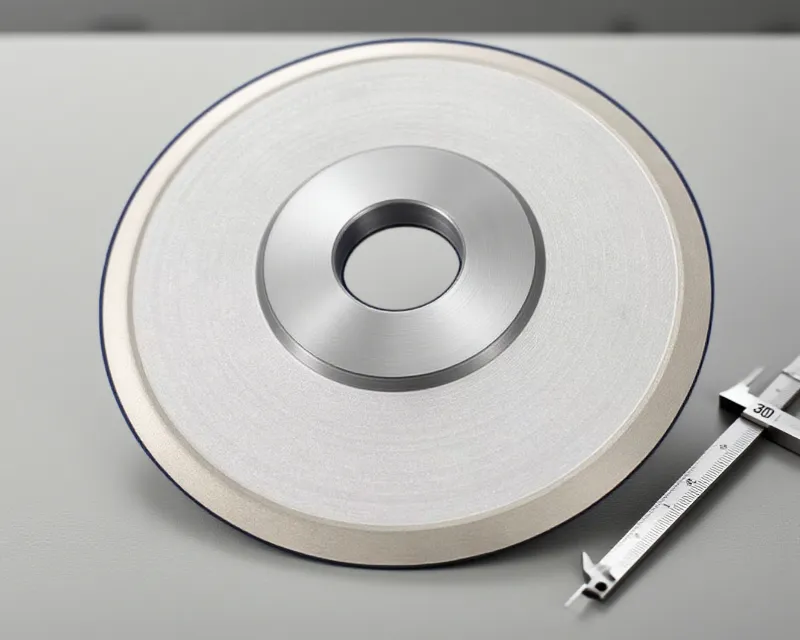

Bonded Abrasives

Bonded abrasives are tools made by mixing alumina powder with binders (such as ceramics, resin, or rubber), followed by forming and curing processes to create tools with specific shapes and strength. Common examples include grinding wheels, mounted points, and grinding discs.

Grinding wheels

These are the most widely used bonded abrasives. Coarse-grained alumina powder (8–60 mesh) is used for rough grinding of castings and forgings. It quickly removes oxide scales, burrs, and extra material. This is ideal for shaping engine blocks and machine tool beds. Medium-grained wheels (80–180 mesh) are used for semi-finish grinding to further refine surfaces and prepare for fine machining. A typical application is the external grinding of bearing rollers.

Mounted points and grinding discs

Small mounted points usually employ medium to fine-grained alumina powder and are suited for localized grinding of molds, cavities, and complex curved surfaces.

Grinding discs, on the other hand, are widely used for deburring metal plates and pipes or cleaning weld seams. Owing to alumina powder’s high wear resistance, these discs can maintain consistent grinding efficiency over long operating periods.

Coated Abrasives

Coated abrasives are made by applying alumina powder with an adhesive onto a substrate such as paper, cloth, or non-woven fabric. Typical products include sandpaper, abrasive cloth, and abrasive belts.

Sandpaper and abrasive cloth

Sandpaper, usually made on paper backing, employs fine-grained alumina powder (e.g., 240–600 mesh) and is used for surface sanding of wood, plastic, and metal materials. In furniture manufacturing, for example, it is used to smooth wood surfaces before applying primer.

Abrasive cloth, which uses fabric as the backing material, has higher strength and often uses medium to coarse alumina grains for rust removal and scale cleaning on metals—such as the surface pretreatment of steel structures.

Abrasive belts

Abrasive belts are highly efficient coated abrasive tools that can be customized by adjusting the grain size of alumina powder to achieve different processing precisions.

Wide belts are used for continuous grinding of sheet or coil materials, such as stainless-steel plate surface finishing. Narrow belts are suited for external grinding of shafts and rods, providing better surface conformity and improved grinding uniformity and efficiency.

Loose Abrasives

Loose abrasives refer to unbonded or uncoated alumina powder particles used in processes such as sandblasting and lapping.

Sandblasting

Coarse-grained alumina powder is propelled at high speed using compressed air to clean workpiece surfaces, removing rust, grease, and old coatings. This process also creates a desired surface roughness to enhance coating adhesion.

It is widely used for surface preparation in shipbuilding, bridge construction, and machinery component manufacturing.

Lapping

In lapping, medium to fine-grained alumina powder is mixed with a grinding liquid to form a slurry. The slurry is then applied between a rotating lap plate and the workpiece to achieve material removal.

For example, in the finishing of automotive gearbox gears, alumina powder lapping can improve tooth surface accuracy and smoothness, thereby reducing operational noise.

Application in the Polishing Field

Metal Polishing

Metal materials such as stainless steel, aluminum alloys, and copper alloys often retain fine scratches after grinding, which must be removed through polishing to enhance appearance and performance.

Rough polishing

Micron-sized alumina powder (5–10 μm) is formulated into polishing pastes or slurries, which are applied using cloth or sisal wheels. This step removes grinding marks and flattens the surface—for instance, in the preliminary polishing of stainless-steel kitchenware.

Fine polishing

Using finer alumina powder (1–3 μm) with high purity, and applying it with soft tools such as wool wheels, enables further reduction of surface roughness and creation of a mirror finish.

This process is commonly employed for high-end bathroom fittings and precision instrument housings.

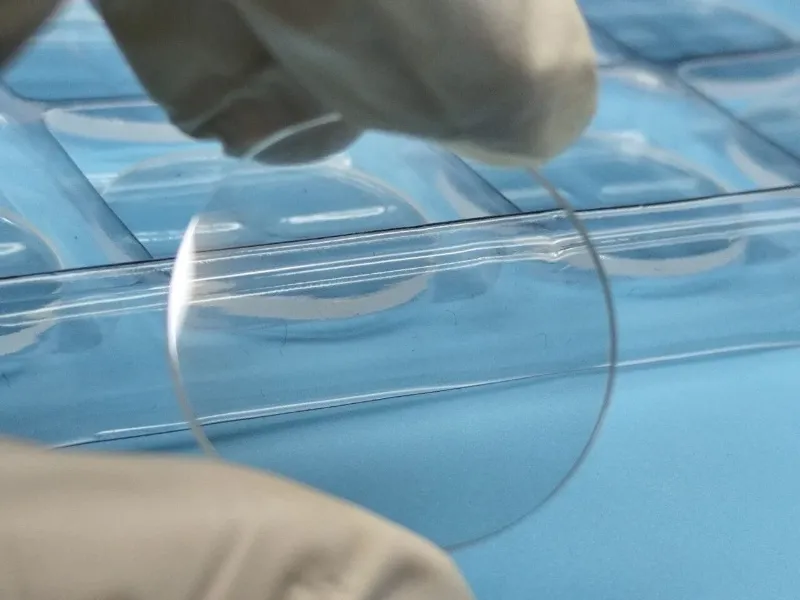

Optical Polishing

Optical components such as lenses, prisms, and optical glass require extremely high surface quality. Even minute scratches or surface irregularities can affect transmittance and imaging accuracy.

High-purity (over 99%) ultrafine alumina powder—with particle sizes below 0.5 μm—is the key material for optical polishing.

During the process, alumina particles interact with the optical glass surface through micro-cutting and friction, gradually removing the defect layer.

For example, in the production of camera and telescope lenses, multiple alumina-based polishing steps are necessary to achieve superior surface accuracy and light transmission.

Semiconductor Polishing

The semiconductor industry demands exceptional surface flatness and cleanliness. Alumina powder is widely used in wafer polishing processes.

In wafer back-thinning and front-side polishing, ultrafine alumina slurry removes damage layers and contaminants to improve surface flatness.

Particularly in the coarse polishing stage of silicon wafers, alumina powder—with its balanced hardness and cutting efficiency—effectively corrects global flatness, laying the foundation for subsequent chemical mechanical polishing (CMP).

Conclusion

With its outstanding combination of properties, alumina powder continues to play a central role in the fields of abrasives and polishing.

From traditional heavy industries to advanced precision manufacturing, its range of applications is constantly expanding.

As material processing and surface technologies evolve, alumina powder is expected to become an even more critical material in emerging high-end applications and key manufacturing processes.