Silica micro-powder is an inorganic non-metallic functional powder material. It has unique physical and chemical properties such as high heat resistance, high insulation, low linear expansion coefficient, and good thermal conductivity. It is widely used in copper-clad laminates, epoxy molding compounds, electrical insulation materials, adhesives, ceramics, and coatings. It also plays an important role in industries such as consumer electronics, home appliances, mobile communications, automotive, aerospace, defense, and wind power. The development of spherical silica directly drives technological progress in these industries. It also improves product performance and quality. In recent years, with the rapid development of microelectronics technology, the quality requirements for microelectronic components have increased significantly. This trend has raised the quality requirements for silica micro-powder. As a result, the preparation of high-purity, ultrafine spherical silica has become a research hotspot.

Overview of Spherical Silica

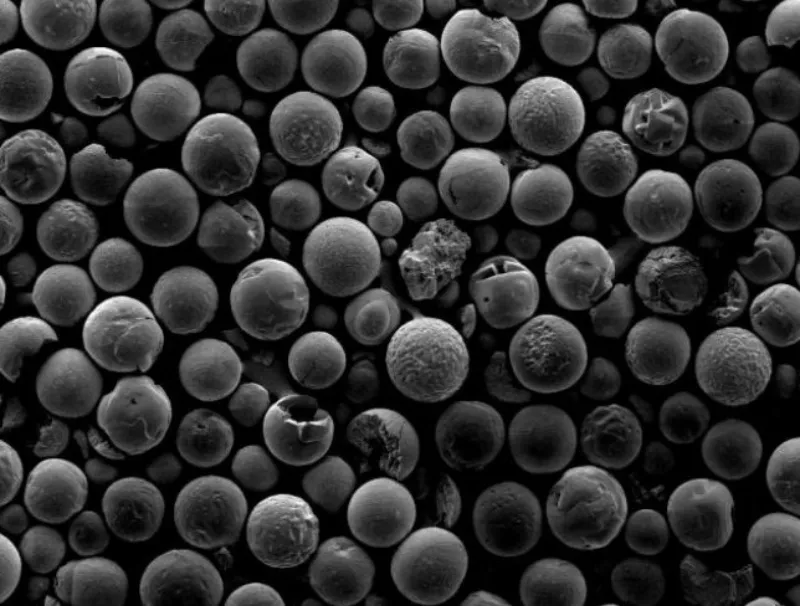

Spherical silica powder refers to white spherical particles composed mainly of amorphous quartz, with particle sizes down to submicron or nanometer levels. It has high heat resistance, high humidity resistance, high filling properties, low stress, and a low friction coefficient.

In addition, spherical silica has extremely high purity. The particle size is small but not prone to agglomeration, and the size distribution is uniform. It also features excellent dielectric properties and an extremely low thermal expansion coefficient. Because of these advantages, spherical silica has broad applications and promising development prospects.

Preparation Processes of Spherical Silica

Currently, the preparation methods of spherical silica are divided into physical and chemical methods. Physical methods include ball milling, spray drying, flame spheroidization, high-temperature fusion spraying, plasma method, self-propagating combustion, flame melting, high-temperature calcination, and direct-combustion (VMC) method. Chemical methods include vapor-phase synthesis, sol-gel, precipitation, and microemulsion techniques.

Physical Methods

Mechanical Milling

Mechanical milling uses crushing equipment and screening systems to produce ultrafine powders. It includes dry and wet milling. Wet milling uses water as the medium and stir mills to produce powders with good dispersion and uniform size.

Spray Drying

Spray drying converts liquid feed into fine droplets using an atomizer. The droplets contact hot air, moisture evaporates, and solid particles form. The dried product is then collected.

Flame Spheroidization

This is the most common method for industrial production. First, high-purity quartz sand is crushed, screened, and purified. The quartz powder enters a high-temperature field produced by fuel gas and oxygen. The powder melts, cools, and forms spherical particles.

In this method, pure oxygen and alkanes generate a controlled flame to maintain a stable temperature field. Multiple nozzles ensure even heating, which improves spheroidization efficiency. Compared with plasma, this method is simpler and more suitable for large-scale industrial production.

High-Temperature Fusion Spraying

Quartz is melted at 2100–2500 °C and then atomized, cooled, and solidified into spherical silica. The product has a smooth surface, 100% spheroidization rate, and amorphous structure.

Plasma Method

Plasma torches generate extremely high temperatures. Quartz or silica powder melts into droplets, and surface tension shapes them into spheres. Rapid cooling forms spherical silica with controllable morphology, high purity, and no agglomeration.

Self-Propagating Combustion

This method involves preparing sodium silicate, silica sol, and a combustion mixture. The mixture undergoes combustion, annealing, decarbonization, washing, and drying to form spherical silica. Advantages include simple equipment, low cost, and no introduction of impurity ions. However, it is still at the laboratory stage.

Flame Melting

Angular silica powder is pretreated by crushing, screening, and purification. Using clean fuels such as acetylene or natural gas, the powder melts in a high-temperature flame and cools into spheres. The result is high-purity, uniform spherical silica.

High-Temperature Calcination

Quartz powder is aged under alkaline conditions, filtered, and dried. The dried material is mixed with a binder, calcined at high temperature, cooled, and ground. After magnetic separation and air classification, spherical silica with high whiteness and purity is obtained. This method remains experimental.

Direct Combustion / VMC

Because flame-melted silica has limitations in purity and particle distribution, some companies use the VMC method. Metal silicon powder reacts directly with oxygen to produce spherical silica with higher purity and more uniform size distribution.

Chemical Methods

Vapor-Phase Method

Silicon halides undergo high-temperature hydrolysis, forming amorphous silica nanoparticles. The products have high purity, primary particle sizes of 7–40 nm, specific surface areas of 50–380 m²/g, and SiO₂ content above 99.8%. However, dispersion in organic media is difficult.

Sol-Gel Method

Metal or inorganic silicon compounds form solutions, sols, and gels, followed by heat treatment to yield silica. This method offers excellent chemical uniformity, high purity, and fine particles. However, raw materials are expensive, and powders may shrink, sinter, or agglomerate.

Precipitation

Sodium silicate and acid react in the presence of surfactants. Careful control of pH and temperature yields uniform spherical silica. This process is simple and low-cost, and suitable for industrial use. However, agglomeration can occur.

Microemulsion

Surfactants stabilize immiscible phases into a uniform emulsion. Within micro-spaces at the phase interface, silica precursors nucleate and grow. After heat treatment, spherical silica particles form.

Comparison of Physical and Chemical Methods for Spherical Silica Preparation

| Method Type | Main Processes | Advantages |

| Physical Methods | Mechanical milling, spray drying, flame spheroidization, high-temperature fusion spraying, plasma method, combustion, flame melting, calcination, VMC | • Mature technology for some methods (e.g., flame spheroidization) • Simple equipment (e.g., spray drying, combustion) • Suitable for large-scale production (flame, fusion spraying) • High purity and smooth surfaces (fusion spraying, plasma) |

| Chemical Methods | Vapor-phase, sol-gel, precipitation, microemulsion | • High purity and uniform particle size • Submicron and nanometer scale achievable • Precise control of morphology • Suitable for high-end applications |

Epic powder

High-purity spherical silica is a key material for large-scale integrated circuits. It is widely used in aerospace, supercomputing, next-generation information technology, defense, and security fields.

With advanced grinding, classification, and surface modification equipment, Epic Powder provides customized solutions for preparing ultrafine spherical silica. Their systems enable stable particle size control, high spheroidization rate, and excellent dispersion. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !