There are various methods for ultrafine powder surface modification, generally categorized into: surface coating, surface chemical modification, mechanochemical modification, capsule-type modification, high-energy modification, and precipitation reaction modification.

Surface Coating Modification

Ultrafine powder surface coating modification involves the use of surface modifiers that do not chemically react with the particle surface. Instead, the coating adheres to the particles through physical methods or van der Waals forces. This method is applicable to most inorganic particles. Coating agents may include surfactants, dispersants, and inorganic compounds.

Powder Modifiers: Quaternary ammonium salts, polymers, organic monomers, amino acids, inorganic intercalators such as carboxylated titanium, metal oxides, and inorganic salts.

Influencing Factors: Raw material properties, reaction environment, intercalator type, and usage.

Suitable Powders: Kaolin, graphite, mica, hydrotalcite, vermiculite, clays, metal oxides, and layered silicates.

Surface Chemical Modification

Surface chemical modification involves organic functional groups adsorbing or chemically reacting with the inorganic powder surface. This method includes free radical reactions, chelation reactions, sol-gel adsorption, and more.

Powder Modifiers: Silanes, titanates, aluminates, zirconium-aluminate, organic chromium compounds, advanced fatty acids and their salts, organic ammonium salts, surfactants, phosphates, unsaturated organic acids, water-soluble organic polymers, etc.

Influencing Factors: Powder surface properties, modifier type, usage, modification process, and equipment.

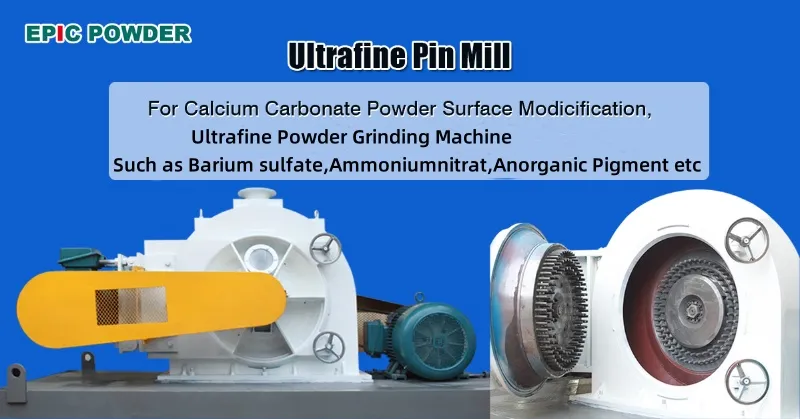

Suitable Powders: Quartz sand, silica micro-powder, calcium carbonate, kaolin, talc, bentonite, barite, wollastonite, mica, diatomite, magnesium hydroxide, barium sulfate, dolomite, titanium dioxide, alumina, and more.

Mechanochemical Modification

Mechanochemical modification refers to the mechanical processes such as grinding, milling, and friction, which alter the mineral lattice structure and increase the system’s energy. This leads to changes in particle properties, enhancing surface activity and facilitating reactions.

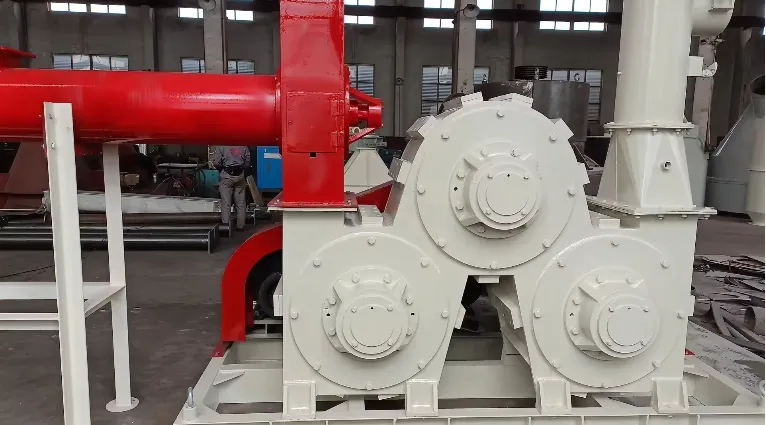

Equipment & Modifiers: Ball mills, air jet mills, high-speed mechanical impact mills, grinding aids, dispersants, and modifiers.

Influencing Factors: Type of grinding equipment, mechanical action, grinding environment (dry, wet, atmosphere), types and amounts of grinding aids or dispersants, mechanical action time, and the crystal structure, chemical composition, and particle size of the material.

Suitable Powders: Kaolin, talc, mica, wollastonite, titanium dioxide, and various other powders.

Capsule-Type Modification

Capsule-type modification is a method where a uniform and relatively thick film covers the surface of powder particles.

High-Energy Modification

High-energy modification uses plasma or radiation treatments to initiate polymerization reactions for modification.

Precipitation Reaction Modification

Precipitation modification involves adding a precipitating agent to a solution containing powder particles, causing modification ions to precipitate and form a coating on the powder surface. Methods include direct precipitation, uniform precipitation, non-uniform nucleation, co-precipitation, and hydrolysis.

Powder Modifiers: Metal oxides, hydroxides, and salts of various inorganic compounds.

Influencing Factors: Raw material properties (particle size, shape, surface functional groups), type of inorganic surface modifiers, slurry pH, concentration, reaction temperature and time, as well as subsequent washing, dehydration, drying, or calcination steps.

Suitable Powders: Titanium dioxide, pearlescent mica, alumina, and other inorganic pigments.

Epic Powder

With over 20 years of experience in fine powder processing, Epic Powder specializes in surface modification solutions. These solutions enhance powder characteristics such as dispersion, stability, and reactivity. Epic Powder uses advanced equipment, including air jet mills, ball mills, and surface modification systems. The company offers customized solutions for industries like materials science, lithium batteries, and coatings. This improves both product performance and production efficiency. Whether using surface coating, chemical modification, or mechanochemical methods, Epic Powder ensures precision and quality in every step of the process.