In the world of powder processing, pulverizers are crucial machines used to reduce the size of materials into fine powders. They are widely employed in various industries, including chemicals, pharmaceuticals, food processing, and mining. Among the different types of pulverizers available, the superfine pulverizer stands out for its ability to produce powders with fine particle sizes, often in the micron or sub-micron range. It has the ability to produce powders with extremely fine particle sizes. These particle sizes are often in the micron or sub-micron range.

While traditional pulverizers also serve this purpose, they operate in different ways and are suited for different applications. Understanding the differences between superfine pulverizers and traditional pulverizers is essential for selecting the right machine for your processing needs. This article will explore the key differences between these two types of pulverizers. It will highlight their design, working principle, capabilities, and applications.

Design and Working Principle

Traditional Pulverizers

Traditional pulverizers include hammer mills, ball mills, and impact mills. These machines typically rely on mechanical force. They are used to crush, grind, or shear materials. These machines are designed to handle a wide range of materials but are usually optimized for coarser grinding.

- Hammer Mills: In a hammer mill, hammers strike the material with high velocity, causing it to break into smaller particles. This is a straightforward mechanism, but it tends to produce a broader particle size distribution and is less effective at achieving fine or superfine powders.

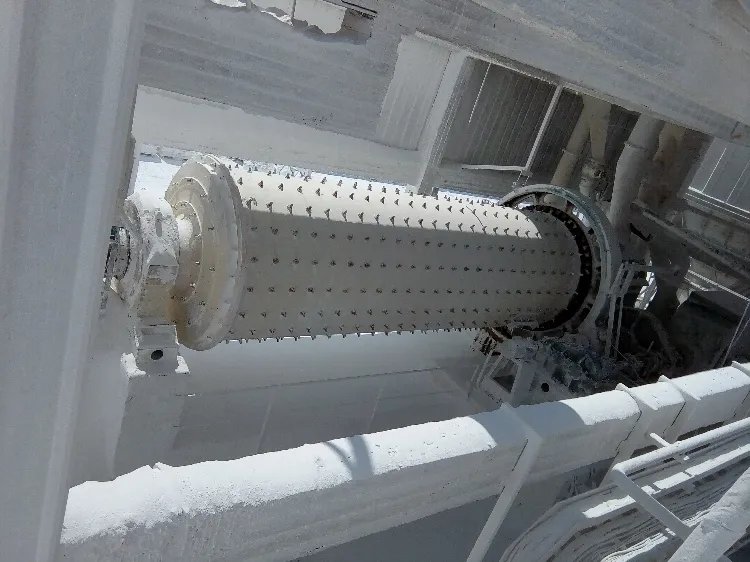

- Ball Mills: Ball mills use rotating drums filled with grinding media (such as steel balls) to crush materials by impact and attrition. While ball mills can produce fine powders, they are generally slower and less energy-efficient for producing ultrafine particles.

- Impact Mills: These mills operate by accelerating the material using high-speed rotating discs or blades, causing the particles to break upon impact with the grinding surfaces. While they can be effective for finer powders than hammer mills, they are not designed for achieving ultra-fine particle sizes consistently.

Superfine Pulverizer

Superfine pulverizers are designed specifically to produce powders with extremely fine and uniform particle sizes. They utilize advanced technologies that combine mechanical force with aerodynamic principles, achieving high-efficiency grinding. Some common types of superfine pulverizer include jet mills, fluidized bed jet mills, and air classifier mills.

- Jet Mills: In a jet mill, compressed air or gas is used to accelerate particles to very high speeds, causing them to collide and break into smaller pieces. The high-speed collisions lead to the production of superfine particles with a narrow size distribution.

- Air Classifier Mills: These mills combine a grinding mechanism with an air classifier that separates fine particles from coarse ones. This enables precise control over the particle size distribution and is ideal for producing high-quality superfine powders.

Particle Size and Distribution

Traditional Pulverizer

Traditional pulverizers are generally effective at producing powders within a larger size range. This range is from hundreds of microns to a few millimeters. However, they struggle to consistently achieve ultrafine particle sizes. The particle size distribution produced by these mills is broader. This means there is a mix of fine and coarse particles. While this may be acceptable for certain applications, it is not ideal for industries. In industries like pharmaceuticals or high-end chemicals, consistent particle size is critical.

- Typical Particle Size: Traditional mills can achieve particle sizes from 20 microns to 1,000 microns or even larger, depending on the material and process conditions.

- Particle Size Distribution: Traditional pulverizers often result in a wider particle size distribution, with both fine and coarse particles present in the output.

Superfine Pulverizer

Superfine pulverizers are engineered to produce very fine particles, often in the micron or sub-micron range, with a narrow particle size distribution. This precision is particularly important in industries that require high-quality powders for sensitive applications.

- Typical Particle Size: Superfine pulverizers can produce powders as fine as 1 micron or even below, allowing for the production of ultra-fine powders that meet stringent requirements.

- Particle Size Distribution: Superfine pulverizers can achieve a much narrower particle size distribution, with very little variation between the particles. This results in a more consistent product that is essential in applications like pharmaceuticals, where uniformity in particle size is critical.

Applications

Traditional Pulverizers:

Traditional pulverizers are suitable for a wide range of materials, including plastics, minerals, food products, and chemicals. They are ideal for applications that do not require extreme precision in particle size or where a wider particle size distribution is acceptable. Industries such as construction, agriculture, and basic chemical processing commonly use traditional pulverizers.

Superfine Pulverizers:

Superfine pulverizer are designed for applications where ultra-fine powders are required, such as in the pharmaceutical, cosmetic, and high-end chemical industries. These industries often demand very specific particle sizes for optimal performance and consistency in their end products. Superfine pulverizers are also used in research and development when creating novel materials with precise characteristics.

Conclusion

In summary, the choice between a superfine pulverizer and a traditional pulverizer depends largely on the specific requirements of the application. Traditional pulverizers are well-suited for coarser grinding and larger particle sizes. Superfine pulverizers excel in producing ultrafine powders with narrow particle size distributions. The higher efficiency and precision of superfine pulverizer make them the preferred choice. They are also able to produce very fine powders. This makes them ideal for industries where quality and consistency are paramount. However, they come with higher initial costs and complexity.

epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !