Silicon carbide (SiC) micro powder is a high-performance structural ceramic material. It features high density, thermal conductivity, bending strength, elastic modulus, and excellent resistance to corrosion and high temperature. Because of these properties, it is widely used in industries with demanding structural requirements.

From Reaction Sintering to Recrystallization: Particle Control as the Core

In reaction sintering, optimized silicon carbide micro powder allow ceramic parts to reach a density of 3.12 g/cm³. This level is close to pressureless sintering standards, with free silicon content controlled to international advanced levels.

For pressureless sintering powders, requirements are even stricter. The powder must reach a purity of 99.2 wt%, with a compaction density of 1.72 g/cm³. After sintering, final products can achieve a density of 3.15 g/cm³.

In the recrystallization field, breakthroughs were achieved by analyzing imported materials and optimizing local processes. From raw material selection to particle shaping and size optimization, technical barriers were overcome. The tap density of coarse powder was successfully increased to 2.004 g/cm³.

SiC Powders for 3D Printing: Breaking Traditional Limitations

Traditional SiC ceramic parts have long manufacturing cycles and high machining difficulty. They struggle to meet the demand for large-scale and complex structures. For oversized components, conventional sintering processes are no longer feasible. This drives enterprises to explore 3D printing technologies.

However, printing large SiC components requires specialized 3D printing powders.

- Raw materials: high-strength, high-density SiC smelting blocks are selected.

- Powdering process: optimized crushing ensures reasonable particle size distribution.

- Particle grading: multi-level particle size distribution enhances one-time molding, density, and strength.

With these advancements, SiC sintered density has gradually improved. It increased from 2.7 g/cm³ to 2.8 g/cm³, and is now approaching 3.0 g/cm³. Today, such powders are widely used in aerospace applications, for example in the production of large reflective mirrors.

From Ceramics to New Attempts in Grinding and Polishing

Silicon carbide demonstrates enormous potential in grinding and polishing applications. With a Mohs hardness of 9.5, second only to diamond, silicon carbide micro powder provides outstanding mechanical strength and wear resistance.

In grinding, SiC powders are applied to glass, ceramics, gemstones, and hard alloys. Their sharp particle morphology enables fast cutting, while maintaining dimensional precision and efficiency.

In polishing, ultra-fine SiC powders are used in wafers, LED substrates, and optical glass. By strictly controlling particle size and distribution, powders can deliver nanometer-level surface finish. This balance of material removal and high surface quality meets the stringent demands of semiconductor, optics, and electronics industries.

With the growth of precision manufacturing and renewable energy, SiC powders are also expanding into CMP (Chemical Mechanical Polishing) slurries. These play a crucial role in chip manufacturing and optoelectronics.

Preparation Process of Silicon Carbide Micro Powders

- Raw material: coarse green SiC is crushed, with purity ≥99%, free carbon and Fe₂O₃ content <0.2%.

- Crushing: two main methods are used in China: intermittent wet ball milling or jet milling.

- Magnetic separation: wet and mechanical methods combined. Wet separation eliminates dust, reduces iron, and improves yield.

- Water classification: separates particle sizes using different settling speeds in water.

- Ultrasonic sieving: solves agglomeration, electrostatics, and fine particle screening challenges.

- Quality inspection: chemical composition, particle size distribution, and other tests are carried out in line with “Silicon Carbide Technical Standards.”

- Byproduct utilization: leftover coarse fractions are processed into abrasive powders. This reduces waste and extends the product chain.

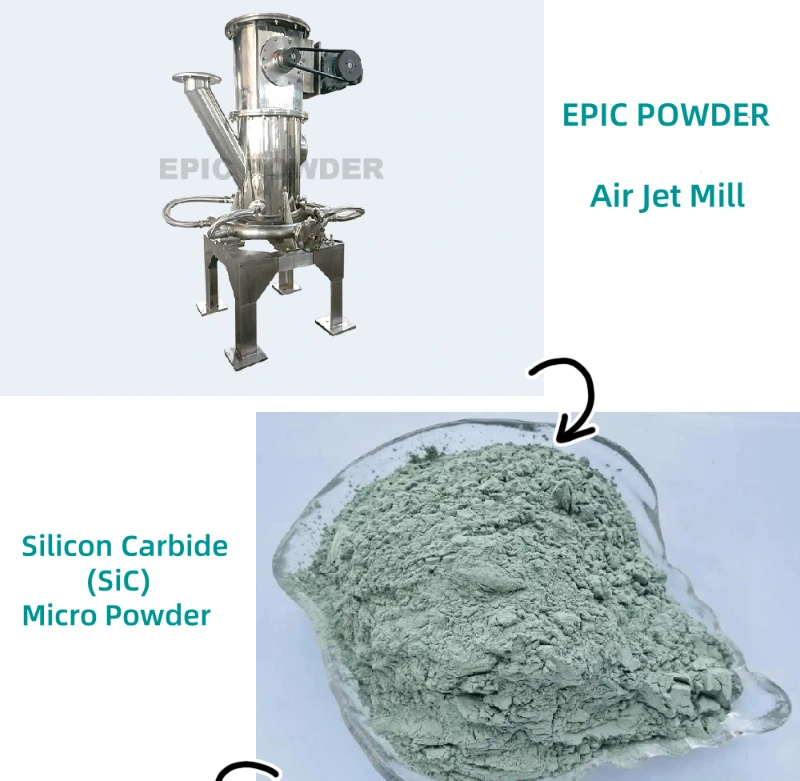

Epic Powder Solutions

The preparation of silicon carbide micro powder places very high demands on equipment. Particle size must be precisely controlled, while minimizing metallic contamination.

Epic Powder, with 20+ years of experience in powder engineering, provides advanced solutions:

- Jet mills: crush particles through inter-particle collision, avoiding metal contamination, ideal for high-purity SiC.

- Ball mill classification production lines: ceramic liners and high-purity grinding media ensure product purity and uniform particle size.

- Surface modification equipment: enhances SiC dispersion and bonding in resins and composites.

The application of silicon carbide micro powders continues to expand. From high-performance ceramics to 3D printing, and into grinding and polishing, SiC shows enormous potential.

Epic Powder supports this transformation with efficient, low-contamination grinding and classification equipment. Its solutions help customers achieve breakthroughs in SiC powder preparation, providing strong momentum for the advancement of the new materials industry.