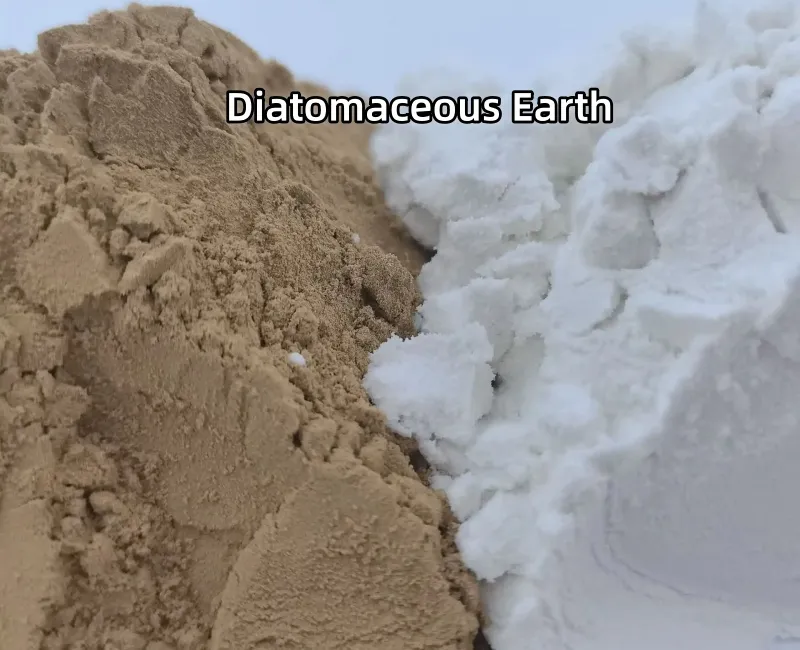

珪藻土(DE)珪藻土(けいそうど、または珪藻泥とも呼ばれる)は、古代の珪藻類の化石から形成された、多孔質で軽量、シリカを豊富に含む堆積岩です。非常に高い多孔度(80~90%)、大きな比表面積、低密度、優れた吸着能、そして優れた熱・化学安定性により、DEは高級コーティング(特にマットな建築用コーティング)、ビールの濾過、機能性充填剤、触媒担体などに広く利用されており、効率的で精密な珪藻土の需要が高まっています。 超微粉砕技術.

しかし、珪藻土の潜在性能を最大限に引き出すには、通常、D90 ≤ 5~10 μm、あるいはD97 ≤ 2~3 μmまで粉砕する必要があります。このような微細粒度を達成することは、タルク、GCC、カオリンの処理よりもはるかに困難です。

珪藻土の超微粉砕における主な課題

超微粉技術の進歩にもかかわらず、DE の独特な物理的特性は工業規模の粉砕に大きな課題をもたらします。

嵩密度が低く空気輸送が困難

- チャレンジ:

DEは嵩密度が極めて低く、表面積が大きいため、空気輸送や分級の際に粉体が「飛び散る」、あるいは運び去られてしまう傾向があり、材料の損失や粉塵処理の必要性の増加につながります。 - 解決:

低速、高気流の搬送システムを設計し、分級構造を最適化して超微粒子への抗力効果を低減します。

構造的損傷と機能特性の損失

- チャレンジ:

DEの性能(多孔性、吸着能力)は、その微細孔構造に依存します。過度または不適切な粉砕、特に高衝撃粉砕は、これらの細孔を潰したり詰まらせたりする可能性があります。 - 解決:

粒子間の衝突が支配的なジェット粉砕などの穏やかな粉砕方法を選択し、高エネルギー媒体の直接的な影響を最小限に抑えます。

高いエネルギー消費と熱蓄積

- チャレンジ:

超微粉砕はエネルギーを大量に消費します。粉砕中に発生する熱によって材料が過熱され、凝集を引き起こし、分散性に影響を与える可能性があります。 - 解決:

粉砕パラメータを最適化し、粉砕室内に効果的な冷却システムを実装し、必要に応じて適切な事前乾燥を確実に行います。

凝集と分散の問題

- チャレンジ:

粒子径が小さくなると、DEの表面積と表面エネルギーは急激に増加します。粉末はファンデルワールス力によって容易に凝集し、コーティングや液体における性能を低下させます。 - 解決:

使用 表面改質 粉砕中または粉砕後に(シラン剤、有機シリコンなど)表面活性を低減するか、下流のアプリケーションで高効率分散剤を適用します。 - 根本的な矛盾:

超微細化を実現 多孔質構造を破壊することなく。

珪藻土の超微粉砕に必須の産業機器

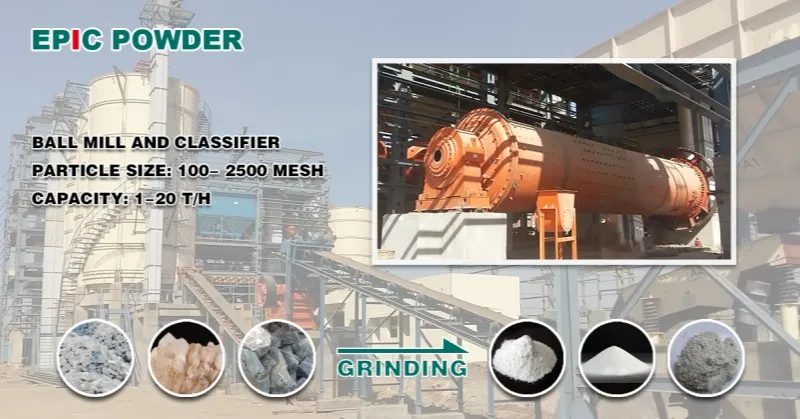

ボールミル+分級システム

DE 超微粉末の最も一般的な乾式処理ルート。

利点:

- 広い粒子サイズ範囲(D97:20μm→3μm)

- 高スループット

- 壊れやすい素材に適しています

- 比較的低コスト

ジェットミル (流動床またはディスク型)

原理と特徴:

高圧気流(空気、蒸気、不活性ガス)を使用して粒子を加速し、高速粒子間衝突と摩擦により超微粉砕を実現します。

アプリケーションの利点:

- 簡単に製品を生産 D97 < 10 μm あるいはさらに細かい

- 非常に狭い粒度分布

- 低密度で壊れやすい珪藻土に特に適しています

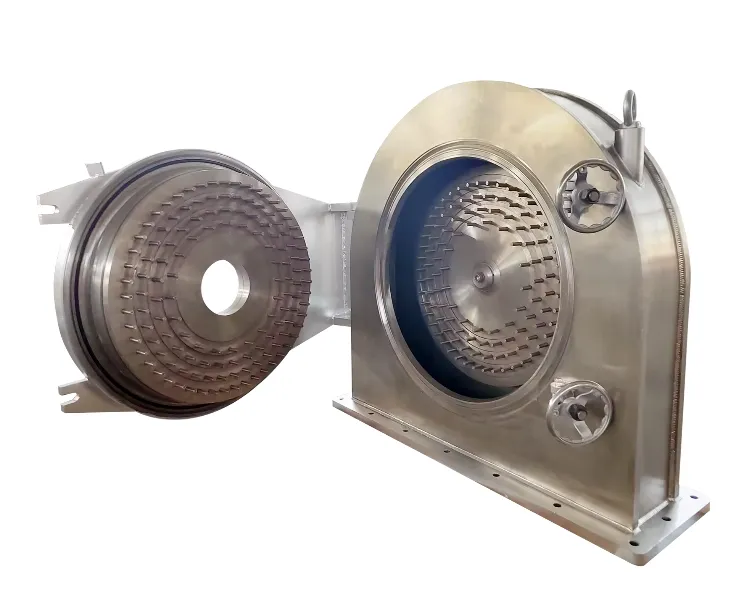

インパクトミル/ピンミル

原理と特徴:

高速回転するローター(ハンマーやピンなど)を使用して、材料に強力な衝撃、せん断、摩擦力を加えます。

アプリケーションの利点:

- 比較的シンプルな構造でメンテナンスも簡単

- 中程度の出力と粒子サイズを必要とする用途に適しています。 10~40μm 範囲

垂直ローラーミル / リングローラーミル

主に325~2000メッシュの微粉末に使用されます。

利点:

- 大容量

- 低エネルギー消費

- 安定した粒子形状

撹拌ミル/湿式超微粉ミル

非常に狭い PSD または表面改質を必要とするハイブリッド プロセスに適しています。

利点:

- 高い研削効率

- 正確な粒子サイズ制御

- 変更プロセスと統合可能

高効率分類器

原理と特徴:

通常は粉砕装置と組み合わせて使用されます。空気流と遠心力を利用して、適切な超微粉を正確に分離し、粗い粒子は粉砕室に戻されます。

アプリケーションの利点:

- 製品の一貫性を確保 狭い粒度分布

- 超微粉体の大規模かつ安定した生産を実現するための重要なコンポーネント

コーティング用超微粒子DEの代表的な仕様(2024~2025年)

| 学年 | D97(μm) | 油吸収量(g/100g) | 白色度(ISO) | SiO₂(%) | 主な用途 |

|---|---|---|---|---|---|

| DE-800 | ≤15 | 130~160 | ≥90 | ≥89 | 一般的な内装コーティング |

| DE-1250 | ≤10 | 140~180 | ≥92 | ≥90 | マットおよびセミマット建築用コーティング |

| DE-UF5(超微粒子) | ≤5~6 | 120~150(修正後) | ≥94 | ≥91 | プレミアムゼロVOC水性マット塗料、コイルコーティング |

| DE-ナノ | ≤2~3 | 100~130(深い修正) | ≥95 | ≥92 | 20–40%シリカ粉末/微粉ワックスマット剤の代替品 |

結論

珪藻土の超微粉砕は、典型的な「高付加価値だが非常に困難な」粉末プロジェクトです。成功の鍵は以下の要素です。

- 低せん断、低温粉砕法(蒸気ジェット粉砕が現在の産業的最良の選択肢です)

- 正確な多段階分類により狭いPSDを実現

- 油の吸収と凝集を減らすためのタイムリーな表面改質

- プロセス全体を通して結晶シリカと水分を厳密に管理

多孔質構造を損なわずに D97 ≤ 5~6 μm の DE を製造できるメーカーは、高級マットコーティングにおいて、マット効率の向上、手触りの滑らかさ、沈降防止特性の改善、全体的な競争力の強化など、大きな利点が得られます。

読んでいただきありがとうございます。この記事がお役に立てれば幸いです。ぜひ下のコメント欄にご意見をお寄せください。また、ご質問等ございましたら、Zeldaのオンラインカスタマーサポートまでお問い合わせください。

— 投稿者 エミリー・チェン