Achieving perfect particle size in superfine alumina grinding is a technical challenge that demands precision beyond raw power. When targeting a steep particle size distribution (PSD) with a D97 below 3μm, conventional milling methods often fall short—leading to broad PSDs, contamination risks, and inconsistent results. The key lies in mastering the interplay of abrasive material handling, contamination control, and state-of-the-art fluidized bed jet mill technology. For industries demanding ultra-high purity and narrow size control, such as advanced ceramics or electronics, understanding these critical factors is essential to optimizing grind quality and performance.

Understanding Material Behavior

Achieving perfect particle size in superfine alumina grinding starts with knowing how alumina behaves under mechanical stress. The material’s hardness, brittleness, and crystal structure play critical roles in how it fractures and grinds down during processing.

Hardness vs. Brittleness

- Alumina has a Mohs hardness of 9, making it extremely resistant to abrasion. This means conventional grinding methods often struggle to reduce particle size efficiently without excessive wear.

- Despite its hardness, alumina’s brittle nature allows for fracture along cleavage planes, which we can exploit in milling to produce fine, sharp particles rather than deforming or smearing the powder.

- Balancing the grinding force to favor fracturing over plastic deformation is key to achieving superfine particles without wasting energy or causing agglomeration.

Crystal Structure: Alpha vs. Gamma Alumina

- Alumina exists mainly in two crystal forms: alpha (α-Al2O3) and gamma (γ-Al2O3).

- Alpha alumina is the most stable, with a dense, corundum crystal lattice, making it much harder and more wear-resistant but tougher to grind finer.

- Gamma alumina is less dense, has higher porosity, and is generally easier to mill down to sub-micron sizes.

- Understanding which phase you are processing helps tailor grinding parameters and select appropriate machinery for desired particle size distribution.

The Wear Factor

- Alumina’s abrasive nature leads to substantial wear on grinding equipment , especially mechanical mills not designed for ceramic powders.

- This wear can lead to contamination and inconsistent particle sizes, undermining contamination-free milling requirements.

- High wear rates demand the use of ceramic-lined grinding equipment and specialized materials to protect internal components while maintaining process efficiency.

Understanding these fundamental material properties is the foundation for optimizing the superfine alumina grinding process. It informs not only the choice of grinding technology but also how to operate it to achieve a steep particle size distribution and excellent specific surface area (BET) for end-use applications such as sintering and specialty ceramics.

Selecting the Right Grinding Technology

When it comes to superfine alumina grinding, picking the right technology is a game changer. Traditional mechanical milling methods, like ball mills, struggle to reach ultra-fine particle sizes efficiently. They often generate excess heat and contamination, which can degrade the purity of sub-micron alumina powder. Plus, mechanical milling hits limits with abrasive materials like alumina, causing faster wear and higher maintenance.

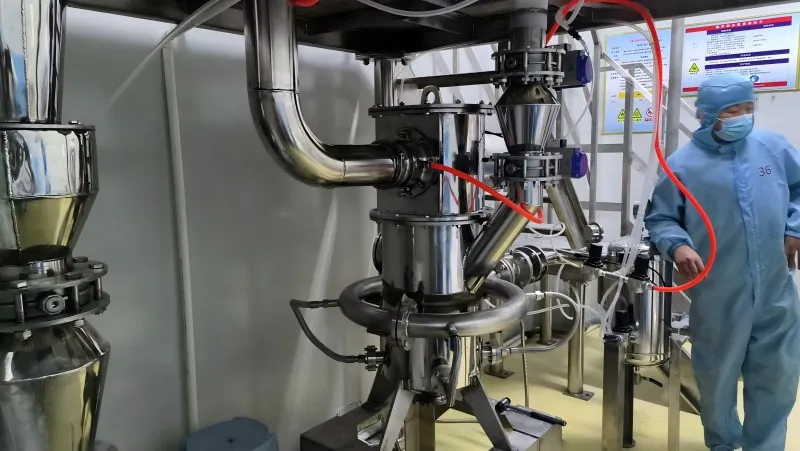

The better option is fluidized bed jet mills. These mills use high-speed compressed air to grind particles by particle collision without metal contact, making them ideal for abrasive and hard materials such as alpha alumina (Mohs hardness 9). This dry grinding process preserves the material’s integrity, preventing unwanted heat buildup and contamination. The airflow dynamics inside a fluidized bed jet mill create a suspended bed of particles, allowing continuous impact and friction between particles themselves rather than between the mill components.

This mechanism allows jet milling to achieve extremely narrow particle size distribution (PSD) and precise control of D97 particle size, sometimes down to around 2 microns or smaller. Because of this, fluidized bed jet mills have become the industry standard for superfine alumina grinding, offering a contamination-free milling environment combined with superior efficiency.

For those looking to understand more about dry grinding and temperature-sensitive processes, exploring spiral jet mill grinding for active pharmaceutical ingredients offers valuable insight into similar airflow and particle dynamics at play.

Precision Classification for Perfect Particle Size

When grinding superfine alumina, precision classification is vital to control the particle size distribution (PSD) and hit exact targets like the D97 particle size. The classifier wheel plays a central role here—it acts like a high-speed sieve, separating fine particles from oversized ones to ensure consistency.

Controlling D97 particle size, which refers to the diameter at which 97% of particles are smaller, is crucial for achieving a narrow and steep PSD. For example, we’ve seen successful cases reaching a D97 of 2.07μm, delivering a super fine, uniform alumina powder ideal for high-performance applications like sintering and coating.

A steep particle size distribution means most particles cluster around the desired size range, improving specific surface area (BET) and enhancing the material’s sintering reactivity and consistency. This precision ultimately boosts product quality in applications requiring sub-micron alumina powder.

For more insights on precision powder processing and classification efficiency, explore our detailed powder metallurgy case studies that highlight classification strategies to optimize superfine powders.

Contamination Control

Contamination control is crucial when grinding superfine alumina, especially because iron contamination can seriously affect the purity and performance of the final product. Iron particles often come from metal parts in standard grinding equipment, which compromises the alumina powder’s sintering reactivity and specific surface area (BET). This contamination not only degrades the final product quality but can also affect downstream processes.

To tackle this, using ceramic protection linings inside the grinding mill is a proven solution. Ceramic-lined grinding mills prevent metal abrasion since ceramic materials are harder and more wear-resistant against Mohs hardness 9 alumina. This creates a contamination-free milling environment essential for producing sub-micron alumina powders without impurity risks.

Another important practice is the “grinding alumina with alumina” philosophy. This means all contact surfaces, including grinding media and liners, are made from alumina or compatible ceramic materials. Doing so maintains purity, reduces wear on equipment, and keeps the particle size distribution (PSD) consistent and clean.

For a deeper dive into abrasion-resistant milling solutions, see our insights on dry grinding processes for non-metallic minerals. Implementing these contamination control methods ensures the highest quality superfine alumina with optimal purity and performance in industrial applications.

Comparative Analysis: Ball Mill + Classifier vs. Jet Mill

When it comes to superfine alumina grinding, choosing between a traditional Ball Mill + Classifier system and a Fluidized Bed Jet Mill can significantly impact your product quality, energy consumption, and contamination levels.

| Feature | Ball Mill + Classifier | Fluidized Bed Jet Mill |

|---|---|---|

| Particle Size Control | Moderate, PSD often broader | Precise, tight particle size distribution (D97 as low as 2.07μm) |

| Energy Consumption | Higher due to mechanical grinding | Lower for equivalent fineness thanks to pneumatic grinding |

| Purity & Contamination | Higher risk of iron contamination | Minimal contamination with ceramic lined mills and alumina-on-alumina grinding |

| Maintenance Complexity | Classifier wheel prone to wear | Requires precise control but less frequent maintenance |

| Grinding Process | Wet or dry milling | Dry grinding, ideal for sub-micron alumina powder |

Energy Cost vs. Purity Trade-Offs

- Ball Milling offers reliability but demands more power due to mechanical impact and attrition. This increases operational costs, especially when targeting fine particle size.

- Jet Milling uses high-speed air jets enabling a dry grinding process with improved air classifier efficiency, reducing energy consumption while achieving superfine particle sizes.

Data Snapshot: Output Curves Comparison

| Particle Size (μm) | Ball Mill + Classifier Output (%) | Jet Mill Output (%) |

|---|---|---|

| >5 | 30 | 5 |

| 3 – 5 | 40 | 20 |

| 1 – 3 | 25 | 50 |

| <1 | 5 | 25 |

The airflow dynamics and precise classification in jet milling yield a steep particle size distribution, critical for high sintering reactivity and consistent sub-micron alumina powder.

In , for high-purity alumina powder with narrow PSD and lower energy costs, jet milling stands out as the industry standard. It supports contamination-free milling and abrasive material handling better than traditional mechanical systems. For a detailed look at optimized operating parameters and case studies on chemical-grade powders, check this in-depth resource on chemical cases in superfine grinding.

Practical Recommendations & Epic Powder Solutions

To consistently achieve perfect particle size in superfine alumina grinding, fine-tuning operational details is key. Here are the practical tips and customized solutions Epic Powder offers to optimize performance and maintain product quality:

Optimizing Operating Parameters

- Airflow speed: Adjust to balance grinding efficiency and heat buildup.

- Feed rate: Keep steady to avoid particle size fluctuations.

- Classifier wheel speed: Fine-tune for precise control over D97 particle size, essential for a narrow particle size distribution (PSD).

- Grinding pressure: Moderate pressure prevents over-grinding and contamination risks.

- Temperature control: Maintain stable ambient conditions to preserve alumina’s sintering reactivity and BET specific surface area.

| Parameter | Recommendation | Benefit |

|---|---|---|

| Airflow Speed | Medium to High | Efficient particle milling |

| Feed Rate | Steady, moderate | Uniform particle size output |

| Classifier Wheel RPM | Adjust to target D97: ~2.07μm | Sharp particle size cut-off |

| Grinding Pressure | Moderate | Avoids over-size fines & wear |

| Temperature | Stable, below critical limits | Preserves material properties |

Customization for Alumina Grades

Alumina grades such as alpha alumina (Mohs hardness 9) and gamma alumina have different grinding behaviors requiring tailored settings:

- Hardness-adjusted settings: Higher hardness needs slower feed and higher airflow.

- Crystal structure considerations: Gamma alumina tends to fracture easier but may produce broader PSD, so classifier tuning is critical.

- Contamination-sensitive grades: Use ceramic protection linings and alumina-on-alumina grinding to minimize wear and iron contamination.

Maintenance Tips for Classifier Wheel

The classifier wheel plays a pivotal role in the particle size distribution. Regular maintenance ensures consistent performance and prolongs equipment life:

- Routine inspection: Check for wear, cracks, or imbalance every production cycle.

- Cleaning: Remove dust and residue buildup to maintain air classifier efficiency.

- Alignment: Ensure the wheel is properly aligned to prevent vibrations or uneven classification.

- Replacement: Schedule parts replacement proactively based on operating hours and wear patterns.

Following these operating and maintenance guidelines is crucial for delivering sub-micron alumina powders that meet high standards of purity and particle uniformity. For more tailored milling strategies and technology insights, check Epic Powder’s proven solutions for superfine alumina grinding.

For deeper understanding of material behavior and grinding technologies, exploring various applications of white carbon black can offer valuable parallels in superfine powder technology.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact Zelda online customer representative for any further inquiries.”

— Posted by Emily Chen