Powder surface modification refers to the targeted treatment of powder surfaces through physical, chemical, or mechanical means. Its purpose is to alter the physicochemical properties of powders or to impart new functions. This technology has become increasingly important in powder processing and applications. It effectively meets the demands of modern materials, advanced processes, and emerging technologies. Through surface modification, the application value and performance of powders can be significantly enhanced.

Eight Major Reasons for Powder Surface Modification

Reason 1: Improving Compatibility and Enhancing Dispersion

In polymer materials such as plastics, rubber, and adhesives, as well as polymer-matrix composite materials, inorganic mineral fillers play a critical role. However, significant differences exist between the surface and interfacial properties of inorganic powders and organic polymer matrices.

As a result, poor compatibility and non-uniform dispersion often occur.

Without surface modification, direct filling or excessive loading of inorganic powders may lead to reduced mechanical strength. In severe cases, material embrittlement can occur. Surface modification optimizes the surface characteristics of inorganic fillers. This significantly improves their compatibility and dispersion within organic matrices.

Consequently, the mechanical strength and overall performance of composite materials are enhanced. More importantly, surface modification enables inorganic fillers to evolve from volume-extending additives into functional fillers. This makes it one of the most fundamental objectives of powder surface modification.

Reason 2: Enhancing Pigment Dispersion and Improving Coating Performance

Another major objective of powder surface modification is to improve pigment and filler dispersion in coatings and paints. At the same time, it enhances gloss, tinting strength, hiding power, and durability.

Pigments and extenders in coatings are predominantly inorganic powders. To ensure good dispersion in organic binders, surface modification is essential to improve wettability and interfacial bonding. In emerging specialty coatings (electrical, magnetic, acoustic, thermal, optical, antibacterial, anticorrosive, radiation-resistant, and decorative coatings), fillers and pigments must not only be ultrafine but also function-specific, making surface treatment indispensable.

In addition, inorganic surface coating—such as coating titanium dioxide with alumina or silica—can further enhance weather resistance and coloring performance.

Reason 3: Providing Good Dispersion Stability and Rheological Properties

With the growing adoption of waterborne architectural coatings, inorganic pigments and fillers must meet stricter requirements. In addition to compatibility with other formulation components, they must exhibit long-term dispersion stability and excellent rheological behavior. For this reason, surface modification is widely applied to pigments and fillers used in water-based coatings. It ensures formulation stability during storage and reliable performance during application.

Reason 4: Imparting Pearlescent Effects

Modern high-value-added products emphasize superior optical effects and visual aesthetics to enhance color richness. This requires surface-treated powder materials that provide excellent gloss and decorative effects.

For example, mica powder surface-modified with metal oxides such as titanium dioxide, chromium oxide, iron oxide, or zirconium oxide can be used in cosmetics, plastics, light-colored rubber, paints, specialty coatings, and leather, producing pearlescent effects and significantly increasing product value.

Reason 5: Improving the Dispersion of Inorganic Pigments

In inorganic–inorganic composite materials, the dispersion of inorganic components has a decisive impact on final performance. In ceramic systems, such as colored ceramic tiles, pigment dispersion directly determines color uniformity and product grade.

Pigments with superior dispersion improve color quality while reducing the consumption of expensive pigments. Therefore, enhancing the dispersion of inorganic pigments in inorganic matrices is critical to the development of inorganic composite materials.

Reason 6: Imparting Functional Properties and Expanding Application Fields

Layered crystal powders can undergo intercalation modification by utilizing weak intermolecular bonding or ion-exchange characteristics between layers, forming new interlayer compounds such as clay or graphite intercalation compounds.

These materials possess novel physicochemical properties absent in the original powders. For example, chemically intercalated graphite exhibits excellent high-temperature resistance, thermal shock resistance, oxidation resistance, corrosion resistance, lubricity, and sealing performance. It serves as a raw material for conductive materials, electrodes, hydrogen storage, flexible graphite, and sealing products, with applications spanning metallurgy, petroleum, chemical engineering, machinery, aerospace, nuclear energy, and new energy sectors.

Organically modified bentonite also demonstrates excellent swelling, adsorption, thixotropy, and bonding properties in nonpolar and weakly polar solvents.

Reason 7: Enhancing Adsorption and Catalytic Properties

Surface modification is essential for improving the activity, selectivity, stability, and mechanical strength of adsorption and catalytic powder materials.

For example, metal oxides, alkaline earth metals, rare earth oxides, or metals such as Cu, Ag, Au, Al, Co, Pt, Pd, and Ni can be loaded onto powder surfaces—such as activated carbon, diatomite, alumina, silica gel, sepiolite, and zeolite—via impregnation methods to optimize performance.

Reason 8: Enabling Nanopowders to Function as True Nanomaterials

Nanopowders are advanced forms of micron-sized powders with enormous application potential. However, their high specific surface area, abundant surface atoms, and high surface energy make them prone to agglomeration during production, storage, transportation, and application, resulting in secondary or larger particles and loss of nano-effects.

Surface modification is therefore critical for improving the application performance and accelerating the industrialization of nanopowders.

Six Main Methods of Powder Surface Modification

Surface modification methods are designed to intentionally alter powder surface properties according to application requirements. At present, six major categories are widely used, each capable of achieving efficient and uniform modification when combined with advanced equipment.

Physical Coating Method

Principle: Polymer or resin coatings are applied to powder surfaces using cold or hot processes to form a coating layer.

Modifiers: Polymers, phenolic resins, furan resins, etc.

Influencing Factors: Particle shape, specific surface area, porosity, coating type and dosage, coating process.

Applicable Materials: Foundry sand, quartz sand.

Equipment: Three-roller coating machines use three rotating rotors to alter internal vortex flow, enabling continuous surface modification. Heat is generated through self-friction, eliminating the need for external heating. Suitable for 325–3000 mesh powders and modifiers such as stearic acid, with low investment and operating costs.

Chemical Coating Method

Principle: Organic functional groups are adsorbed or chemically bonded onto inorganic powder surfaces through dry or wet processes, including free-radical reactions, chelation, and sol adsorption.

Modifiers: Silane, titanate, aluminate, zirconium aluminate coupling agents; fatty acids and salts, organic ammonium salts, surfactants, phosphates, unsaturated organic acids, water-soluble polymers.

Applicable Materials: Quartz sand, silica powder, calcium carbonate, kaolin, talc, bentonite, barite, wollastonite, mica, diatomite, brucite, barium sulfate, dolomite, titanium dioxide, aluminum hydroxide, magnesium hydroxide, alumina, etc.

Equipment:

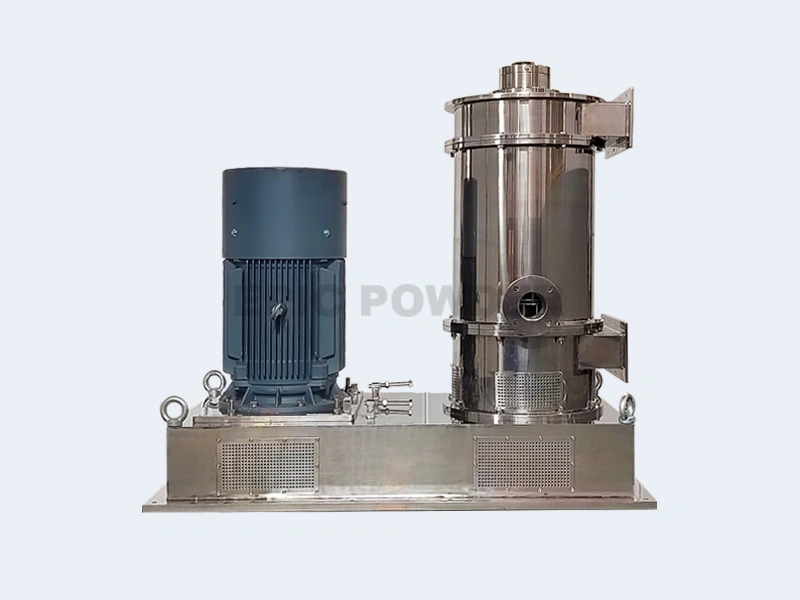

- Turbo mill coating machines with adjustable rotor–stator gaps and linear speeds up to 130 m/s

- Pin mill coating machines with counter-rotating pin discs providing high shear for uniform coating and energy efficiency

Precipitation Reaction Method

Principle: Inorganic compounds precipitate onto particle surfaces, forming one or multiple coating layers to improve properties such as gloss, tinting strength, hiding power, color retention, weather resistance, and electrical/magnetic/thermal properties.

Modifiers: Metal oxides, hydroxides, and inorganic salts.

Applicable Materials: Titanium dioxide, pearlescent mica, alumina pigments.

Equipment: Chemical reactors combined with honeycomb mill coating machines for post-treatment, achieving coating rates up to 99.2% and activation rates up to 99.8%.

Mechanochemical Method

Principle: Strong mechanical forces during ultrafine grinding activate powder surfaces, altering crystal structures, solubility, adsorption behavior, and chemical reactivity.

Modifiers: Grinding aids, dispersants, surface modifiers.

Applicable Materials: Kaolin, talc, mica, wollastonite, titanium dioxide.

Equipment: Ball mills, jet mills, high-speed impact mills, pin mills, honeycomb mills, turbo mills, and three-roller coating machines capable of simultaneous dispersion, coating, drying, and shaping—even for ultrafine powders ≤1 μm or <100 nm.

Intercalation Modification Method

Principle: Weak interlayer bonding or ion-exchange properties of layered minerals are utilized to modify interface characteristics via ion exchange or chemical reactions.

Modifiers: Quaternary ammonium salts, polymers, organic monomers, amino acids, metal oxides, inorganic salts.

Applicable Materials: Kaolin, graphite, mica, hydrotalcite, vermiculite, rectorite, layered silicates, and metal oxides.

Equipment: Primarily chemical reactors, supplemented by mechanical dispersion equipment such as turbo mills.

High-Energy Surface Modification Method

Principle: High-energy treatments such as ultraviolet radiation, infrared radiation, corona discharge, plasma treatment, electron beam irradiation, or microwave activation modify powder surfaces.

Examples include plasma-treated calcium carbonate for improved PP adhesion, infrared-grafted carbon black for better dispersion, and plasma-activated porous silica with increased hydroxyl content.

Limitations: Technically complex, high cost, and difficult industrialization.

Applicable Materials: Calcium carbonate, carbon black, silica.

Equipment: Specialized radiation equipment, often combined with turbo mills or pin mills for post-processing optimization.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact Zelda online customer representative for any further inquiries.”

— Posted by Emily Chen