Với sự tiến bộ không ngừng của công nghệ công nghiệp, cellulose, một vật liệu polymer tự nhiên quan trọng, đã dần dần đóng vai trò ngày càng quan trọng trong nhiều ngành công nghiệp khác nhau. Ứng dụng rộng rãi của nó trong các ngành công nghiệp thực phẩm, dược phẩm, mỹ phẩm và sản xuất giấy đã thúc đẩy sự phát triển nhanh chóng của các thiết bị sản xuất liên quan, đặc biệt là thiết bị chế biến bột. Là một công cụ quan trọng để sản xuất và chế biến bột celluloseThiết bị nghiền bột đóng vai trò quan trọng trong việc cải thiện hiệu quả sản xuất và chất lượng sản phẩm.

Đặc điểm cơ bản của Cellulose

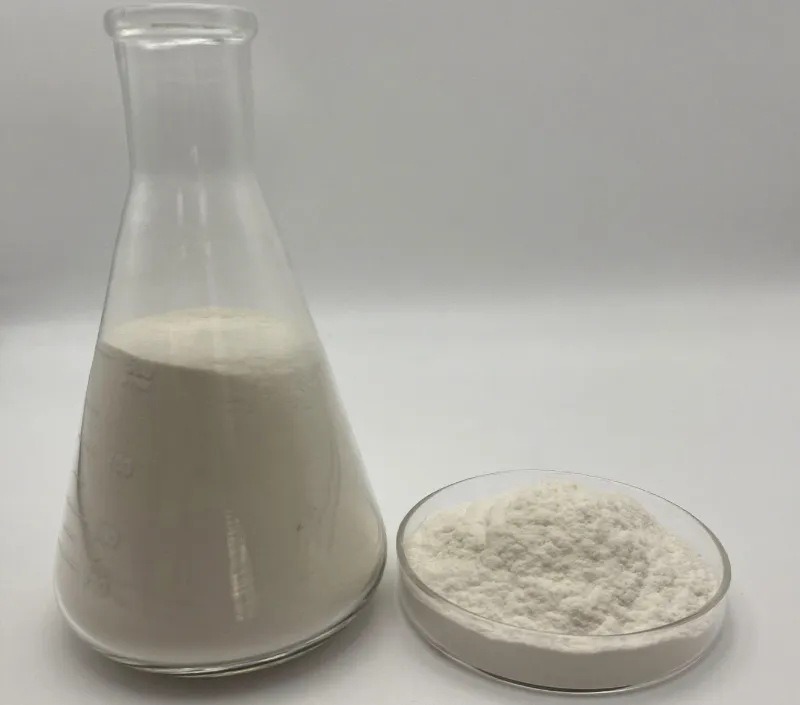

Cellulose là một polysaccharide được cấu tạo từ các đơn vị glucose và được tìm thấy trong thành tế bào thực vật. Nó được biết đến với độ bền, độ đàn hồi và độ ổn định hóa học cao. Nhờ khả năng phân hủy sinh học và không độc hại, vật liệu cellulose ngày càng được ứng dụng rộng rãi trong các ngành công nghiệp hiện đại. Bột cellulose, là một chất phụ gia hoặc vật liệu nền phổ biến trong dệt may, thực phẩm, dược phẩm và mỹ phẩm, có khả năng hấp thụ nước, độ dẻo và tương thích sinh học lý tưởng.

Quy trình sản xuất bột Cellulose

Quy trình sản xuất bột vật liệu cellulose thường bao gồm các bước chiết xuất, sấy khô, nghiền và sàng. Mỗi bước đều đòi hỏi công nghệ tiên tiến để đảm bảo sản phẩm cuối cùng đạt tiêu chuẩn chất lượng. Việc lựa chọn thiết bị xử lý bột là rất quan trọng để đạt được điều này.

Khai thác nguyên liệu thô

Cellulose chủ yếu được chiết xuất từ sợi thực vật và thường đòi hỏi các phương pháp hóa học hoặc cơ học để thu được vật liệu cellulose có độ tinh khiết cao. Quá trình này bao gồm các phương pháp xử lý vật lý và hóa học như chiết xuất bằng dung môi, xử lý axit-bazơ, v.v.

Quá trình sấy khô

Vật liệu cellulose chiết xuất cần được sấy khô để loại bỏ độ ẩm. Thiết bị sấy phổ biến bao gồm máy sấy tầng sôi và máy sấy phun. Các thiết bị này có thể kiểm soát hiệu quả nhiệt độ và độ ẩm sấy, đảm bảo cellulose không bị phân hủy do nhiệt độ quá cao.

Quá trình nghiền

Nghiền là một bước quan trọng trong quá trình chế biến cellulose. Nguyên liệu cellulose thường cần được nghiền vật lý thành bột có kích thước hạt khác nhau để đáp ứng các yêu cầu ứng dụng khác nhau. Thiết bị nghiền phổ biến bao gồm máy nghiền khí nén, máy nghiền phân loại khí nén, máy nghiền bi và máy nghiền rung. Máy nghiền khí nén đặc biệt thích hợp để nghiền các vật liệu nhạy nhiệt vì nó hầu như không sinh nhiệt, ngăn ngừa hiệu quả sự phân hủy nhiệt của vật liệu cellulose.

Sàng lọc và phân loại

Sau khi nghiền, cellulose cần được sàng lọc và phân loại để đảm bảo kích thước hạt đồng đều, phù hợp với nhiều ứng dụng khác nhau. Máy phân loại khí nén và máy tách ly tâm hiệu quả có thể phân loại chính xác bột, loại bỏ các hạt thô và bột mịn, đảm bảo tính đồng nhất và ổn định của sản phẩm.

Vai trò của thiết bị nghiền bột trong chế biến vật liệu xenlulo

Chất lượng sản xuất bột cellulose chịu ảnh hưởng trực tiếp bởi thiết bị nghiền bột. Dưới đây là một số loại thiết bị nghiền bột phổ biến được sử dụng trong quá trình chế biến cellulose:

Máy nghiền khí nén

Máy nghiền khí nén sử dụng luồng khí tốc độ cao để nghiền vật liệu thành dạng siêu mịn, lý tưởng cho việc xử lý bột cellulose nhạy nhiệt. Máy nghiền khí nén tránh được nhiệt sinh ra trong các quy trình nghiền cơ học truyền thống, đảm bảo chất lượng bột cellulose vẫn nguyên vẹn trong khi vẫn duy trì hiệu suất sản xuất cao.

Máy nghiền phân loại không khí

Máy nghiền ACM kết hợp nghiền và phân loại trong một thiết bị duy nhất, mang lại hiệu quả cao trong việc kiểm soát chính xác sự phân bố kích thước hạt trong bột cellulose. Máy nghiền sử dụng luồng khí tốc độ cao để đẩy nhanh các hạt vào vùng phân loại, nơi chúng được phân loại theo kích thước. Quá trình này đảm bảo bột mịn được tách ra khỏi vật liệu thô, cho phép sản xuất các hạt có kích thước đồng đều và cải thiện độ đồng nhất của sản phẩm. Máy nghiền phân loại bằng khí đặc biệt hữu ích khi cần cả nghiền mịn và kiểm soát kích thước chính xác trong quá trình chế biến vật liệu cellulose.

Máy nghiền bi

Máy nghiền bi thường được sử dụng cho sản xuất quy mô lớn, xử lý các hạt nguyên liệu cellulose có kích thước lớn hơn. Khi máy nghiền quay, nguyên liệu được nghiền dần thành bột mịn. Sau thời gian vận hành dài, máy nghiền bi đảm bảo phân phối kích thước hạt đồng đều, phù hợp với môi trường sản xuất quy mô lớn.

Thiết bị phân loại

Ngoài máy nghiền phân loại khí, các thiết bị phân loại truyền thống như máy phân loại khí và máy tách ly tâm cũng có thể được sử dụng để tách bột có kích thước hạt khác nhau. Các thiết bị này đảm bảo chỉ có kích thước hạt mong muốn mới được đưa vào công đoạn sản xuất tiếp theo, nâng cao tính đồng nhất và chất lượng sản phẩm.

Ứng dụng của bột Cellulose trong nhiều ngành công nghiệp khác nhau

Bột cellulose có ứng dụng rộng rãi trong nhiều ngành công nghiệp khác nhau, chủ yếu tập trung vào các lĩnh vực sau:

Ngành công nghiệp thực phẩm

Vật liệu cellulose được sử dụng rộng rãi như một phụ gia thực phẩm tự nhiên, đóng vai trò là chất làm đặc, chất ổn định và chất nhũ hóa. Nó cải thiện kết cấu và hình thức của thực phẩm, đồng thời kéo dài thời hạn sử dụng. Bột cellulose cũng được sử dụng làm nguồn chất xơ, thúc đẩy sức khỏe đường ruột.

Ngành công nghiệp dược phẩm

Trong ngành dược phẩm, bột cellulose thường được sử dụng trong các công thức thuốc. Nó vừa đóng vai trò là chất mang thuốc vừa giúp kiểm soát tốc độ giải phóng thuốc. Vật liệu cellulose được sử dụng rộng rãi trong các dạng viên nén, viên nang và thuốc tiêm.

Ngành công nghiệp mỹ phẩm

Trong mỹ phẩm, bột cellulose được sử dụng như một chất nhũ hóa, chất làm đặc và chất ổn định. Nó giúp điều chỉnh kết cấu của mỹ phẩm, tăng cường độ ổn định và khả năng sử dụng.

Ngành công nghiệp sản xuất giấy

Vật liệu cellulose là một trong những nguyên liệu thô cơ bản trong ngành sản xuất giấy. Bột cellulose có thể được thêm vào giấy để tăng cường độ bền, độ cứng và khả năng in ấn.

Bột Epic

Khi cellulose tiếp tục tìm thấy những ứng dụng mới trong nhiều ngành công nghiệp, nhu cầu về thiết bị chế biến bột cellulose cũng tăng lên. Epic Powder, nhà sản xuất thiết bị chế biến bột chuyên nghiệp, cung cấp các giải pháp hiệu quả như máy nghiền khí, máy nghiền phân loại khí, máy nghiền bi và thiết bị phân loại để giúp khách hàng đạt được hiệu quả nghiền và phân loại chính xác trong quá trình chế biến vật liệu cellulose. Thông qua các giải pháp thiết bị tùy chỉnh, Epic Powder hỗ trợ các doanh nghiệp nâng cao hiệu quả sản xuất, tối ưu hóa chất lượng sản phẩm và đáp ứng các yêu cầu khắt khe của nhiều ngành công nghiệp về bột cellulose.