Bạn có cảm thấy choáng ngợp trước sự đa dạng của các công nghệ nghiền trên thị trường? Với rất nhiều lựa chọn thiết bị nghiền siêu mịn, làm thế nào để chọn được thiết bị phù hợp nhất? Đây là câu hỏi quan trọng quyết định sự thành công của dây chuyền sản xuất của bạn. Lựa chọn sai sẽ dẫn đến phân bố kích thước hạt (PSD) không đồng nhất, tiêu thụ năng lượng cao ngất trời, hoặc tệ hơn là ô nhiễm sản phẩm. Lựa chọn đúng sẽ đảm bảo hiệu quả, độ tinh khiết và khả năng mở rộng. Trong hướng dẫn này, chúng ta sẽ đi sâu hơn các thông số kỹ thuật chung chung trong catalog. Bạn sẽ học được một khuôn khổ thực tiễn, dựa trên kỹ thuật để lựa chọn máy móc hoàn hảo phù hợp với các đặc tính vật liệu cụ thể của bạn – từ độ cứng Mohs đến độ nhạy nhiệt. Cho dù bạn đang phân vân giữa máy nghiền tầng sôi phun tia hay máy nghiền phân loại khí cơ học, đây chính là lộ trình bạn cần.

Chúng ta cùng bắt đầu nào.

Hiểu rõ các yêu cầu cốt lõi của bạn trước khi so sánh thiết bị.

Việc lựa chọn thiết bị nghiền siêu mịn phù hợp không chỉ đơn thuần là tìm kiếm máy móc mạnh nhất trên thị trường; mà là việc kết hợp các khả năng kỹ thuật cụ thể với các yêu cầu riêng biệt của vật liệu của bạn. Tại EPIC Powder Machinery, chúng tôi tuân thủ triết lý “Một khách hàng, một thiết kế” vì chúng tôi biết rằng các giải pháp có sẵn thường không đáp ứng được các tiêu chuẩn công nghiệp chính xác. Trước khi yêu cầu báo giá, bạn phải xác định rõ các thông số quy trình của mình để đảm bảo thiết bị mang lại hiệu quả và chất lượng cần thiết.

Xác định độ mịn mục tiêu và tiêu chuẩn D97

Yếu tố quyết định chính trong việc lựa chọn thiết bị nghiền siêu mịn là kích thước hạt yêu cầu, cụ thể là... Yêu cầu về kích thước hạt D97Chỉ số này cho thấy 97% hạt của bạn có đường kính nhỏ hơn đường kính quy định.

- Vi mô hóa (1–10 μm): Đối với các hoạt chất dược phẩm (API) hoặc vật liệu pin cao cấp, bạn có thể cần máy nghiền tầng sôi (Fluidized Bed Jet Mill) hoặc máy nghiền phân loại bằng khí (Air Classifier Mill) độ chính xác cao.

- Nghiền mịn (10–45 μm): Máy nghiền va đập cơ học tiêu chuẩn có thể đủ dùng cho khoáng sản hoặc hóa chất số lượng lớn, nơi độ chính xác cực cao không quá quan trọng.

Hình thái hạt và kiểm soát phân bố kích thước hạt (PSD).

Ngoài kích thước, hình dạng và sự phân bố của các hạt cũng quyết định hiệu suất sản phẩm. Đạt được sự phân bố kích thước hạt (PSD) hẹp là điều cần thiết để duy trì tốc độ phản ứng ổn định trong hóa chất hoặc khả năng chảy trong lớp phủ.

- Hình thái họcỨng dụng của bạn yêu cầu các hạt hình cầu để đạt mật độ đóng gói cao, hay các hạt hình vảy để đạt độ phủ tối ưu?

- Kiểm soát PSDNếu quy trình của bạn yêu cầu điểm phân loại nghiêm ngặt để loại bỏ các hạt thô, chúng tôi sẽ tích hợp các thiết bị phân loại khí hiệu suất cao (dòng HTS) vào hệ thống để tái chế vật liệu quá cỡ trở lại khu vực nghiền.

Năng lực sản xuất: Quy mô phòng thí nghiệm so với quy mô công nghiệp

Quy mô thiết bị nghiền siêu mịn sẽ phụ thuộc vào giai đoạn sản xuất hiện tại của bạn.

- Giai đoạn Nghiên cứu và Phát triểnChúng tôi khuyến nghị sử dụng máy nghiền thí nghiệm ba trong một được thiết kế cho các mẻ nhỏ. Loại máy này cho phép thu thập dữ liệu và thử nghiệm tính khả thi mà không cần chi phí vận hành của một nhà máy hoàn chỉnh.

- Sản xuất hàng loạtĐối với nhu cầu sản xuất số lượng lớn, chúng tôi thiết kế các hệ thống liên tục có khả năng xử lý hàng tấn mỗi giờ, đảm bảo quá trình mở rộng quy mô liền mạch từ phòng thí nghiệm đến công nghiệp.

Phân tích nhu cầu của quy trình hạ nguồn

Nghiền hiếm khi là bước cuối cùng. Bạn phải xem xét bột sẽ được sử dụng như thế nào ngay sau khi nghiền.

- Biến đổi bề mặt: Nếu vật liệu của bạn cần phủ lớp (ví dụ: đối với chất độn nhựa hoặc cao su), chúng tôi có thể tích hợp thiết bị xử lý bề mặt (như máy nghiền trục hoặc máy nghiền turbo) trực tiếp vào dây chuyền nghiền để giảm bớt các bước trong quy trình.

- Bao bì: Các hệ thống đóng gói tự động yêu cầu mật độ khối lượng riêng ổn định, điều này chịu ảnh hưởng trực tiếp bởi phương pháp nghiền được sử dụng.

Hướng dẫn tham khảo nhanh: Đối chiếu yêu cầu với tác động của thiết bị

| Yêu cầu cốt lõi | Yếu tố quan trọng cần xem xét | Ảnh hưởng đến việc lựa chọn thiết bị |

|---|---|---|

| Độ mịn mục tiêu | Giá trị D97 (ví dụ: 2μm so với 20μm) | Xác định nhu cầu sử dụng máy nghiền khí nén (mịn hơn) so với máy nghiền cơ khí (thô hơn). |

| Chiều rộng PSD | Phân bố dốc so với phân bố rộng | Máy phân loại không khí độ chính xác cao là bắt buộc đối với các khúc cua gấp. |

| Thông lượng | kg/giờ so với tấn/giờ | Xác định kích thước hệ thống và nhu cầu nguồn điện phụ trợ. |

| Chức năng | Mài so với phủ | Có thể cần đến các máy phủ tích hợp hoặc hệ thống lai. |

Các đặc tính vật liệu quan trọng quyết định việc lựa chọn thiết bị nghiền siêu mịn.

Trước khi xem xét bất kỳ loại máy móc nào, chúng ta phải xem xét nguyên vật liệu của bạn. Theo kinh nghiệm của tôi, 90% các sự cố thiết bị xảy ra là do người mua bỏ qua những hạn chế vật lý của nguyên liệu thô. Tại EPIC Powder Machinery, chúng tôi hoạt động theo nguyên tắc “Một khách hàng, một thiết kế” vì các vật liệu có phản ứng khác nhau dưới tác động của ứng suất. Dưới đây là cách các đặc tính cụ thể chi phối quyết định.

Các chiến lược thang đo độ cứng Mohs

Độ cứng của vật liệu quyết định độ mài mòn của máy móc và năng lượng cần thiết để phá vỡ nó.

- Mềm đến trung bình (Mohs 1–3): Các vật liệu như bột talc hoặc các sản phẩm nông nghiệp rất dễ gia công. Máy nghiền cơ học kiểu va đập có hiệu quả về chi phí trong trường hợp này. Đối với các vật liệu dạng sợi hoặc hữu cơ, một Máy nghiền Turbo Nó thường được lựa chọn vì khả năng cắt tốc độ cao.

- Cứng (Mohs 4–7): Khi gặp phải silica hoặc các khoáng chất cứng, các bộ phận cơ khí sẽ bị mòn quá nhanh. Bạn cần máy nghiền có độ cứng Mohs tương thích, hoạt động dựa trên sự va chạm giữa các hạt, chẳng hạn như máy nghiền tầng sôi (Fluidized Bed Jet Mills), để giảm thiểu sự mài mòn.

- Cực cứng (Mohs 7+): Đối với kim cương hoặc cacbua silic, chỉ có năng lượng luồng khí chuyên dụng mới có tác dụng.

Nhạy cảm với nhiệt và độ ẩm

Nghiền nhỏ các vật liệu nhạy nhiệt là một thách thức lớn. Quá trình nghiền cơ học tạo ra ma sát, chuyển hóa thành nhiệt. Nếu vật liệu của bạn có điểm nóng chảy thấp (như nhựa, sáp hoặc một số dược phẩm), máy nghiền tiêu chuẩn sẽ biến bột của bạn thành một mớ hỗn độn dính bết bên trong buồng nghiền.

- Quy tắc về độ ẩm: Đối với quá trình nghiền khô, chúng tôi thường yêu cầu độ ẩm phải dưới 4%. Bất cứ giá trị nào cao hơn thường yêu cầu bước sấy khô trước.

- Kiểm soát nhiệt độ: Đối với các sản phẩm nhạy cảm với nhiệt, chúng tôi sử dụng luồng không khí để dẫn nhiệt ra ngoài hoặc lắp đặt áo khoác làm mát.

Độ mài mòn và tốc độ mài mòn

Độ mài mòn không chỉ phụ thuộc vào độ cứng; mà còn phụ thuộc vào cách các hạt mài cắt. Vật liệu có độ mài mòn cao sẽ làm mòn các lớp lót thép tiêu chuẩn chỉ trong vài ngày.

- Bảo vệ chống mài mòn: Chúng tôi chuyển sang sử dụng lớp lót bằng gốm (nhôm oxit hoặc zirconia) hoặc polyurethane (PU).

- BẢO TRÌ: Nếu bạn bỏ qua vấn đề mài mòn, chi phí thay thế các bộ phận hao mòn sẽ tăng vọt, và thời gian ngừng hoạt động sẽ làm giảm lợi nhuận.

Tiêu chuẩn về độ tinh khiết và ô nhiễm

Bạn đang sản xuất xi măng hay dược phẩm? Tiêu chuẩn của hai ngành này hoàn toàn khác nhau.

- Công nghiệp: Sự nhiễm bẩn sắt ở mức độ nhỏ có thể chấp nhận được.

- Thực phẩm & Dược phẩm: Yêu cầu xử lý bột không bị nhiễm bẩn. Chúng tôi sử dụng thép không gỉ (304/316) và lớp lót gốm để đảm bảo không có ô nhiễm kim loại.

- Vật liệu pin: Khi xử lý Giải pháp nghiền siêu mịn và phân loại vật liệu pin lithiumChúng tôi kiểm soát chặt chẽ các tạp chất từ tính (mức PPB) vì ngay cả bụi kim loại siêu nhỏ cũng có thể gây đoản mạch pin.

Những lưu ý đối với các vật liệu cụ thể

- Polyme: Chúng thường dai và đàn hồi. Chúng cần lực cắt hơn là lực va đập.

- API (Hoạt chất dược phẩm): Yêu cầu vi phân hóa chính xác (1–10 μm) với kiểm soát PSD nghiêm ngặt.

- Các hợp chất lithi: Cần một hệ thống khép kín với khí trơ bảo vệ để ngăn ngừa quá trình oxy hóa và hấp thụ hơi ẩm.

Các loại thiết bị nghiền siêu mịn chính

Việc lựa chọn máy móc phù hợp không phải là tìm kiếm chiếc máy “tốt nhất”, mà là chiếc máy phù hợp với các yêu cầu cụ thể của quy trình sản xuất của bạn. Tại EPIC Powder Machinery, chúng tôi phân loại các giải pháp dựa trên cơ chế hoạt động, yếu tố ảnh hưởng trực tiếp đến độ mịn, công suất và chi phí.

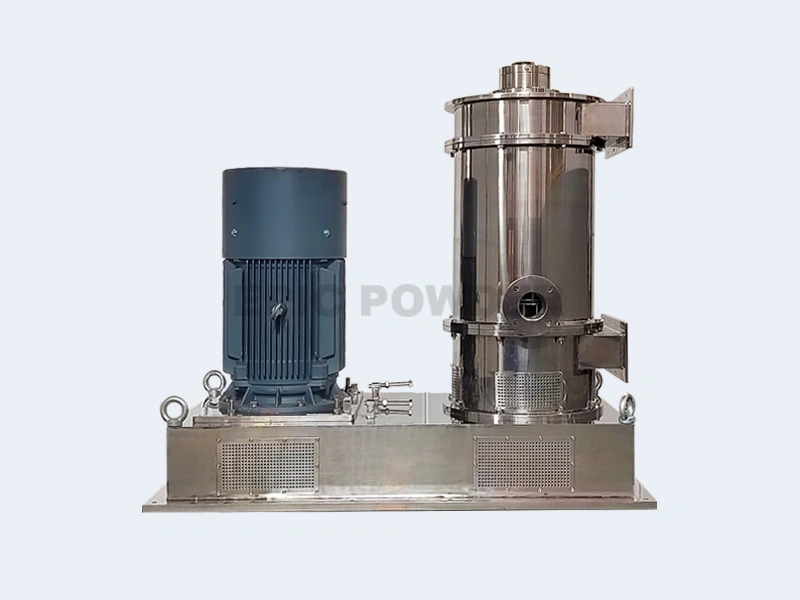

Máy phay cơ khí kiểu va đập: Công cụ làm việc hiệu quả về chi phí

Đối với các vật liệu có độ cứng Mohs dưới 5 và độ mịn mục tiêu từ 10–45 μm, máy nghiền va đập cơ học là giải pháp tối ưu. Loại máy này bao gồm máy nghiền phân loại bằng khí (ACM) và máy nghiền trục. Chúng hoạt động dựa trên rôto tốc độ cao để đập vỡ các hạt vào lớp lót hoặc stato.

- Phù hợp nhất cho: Các thành phần thực phẩm, hóa chất và đá vôi.

- Ưu điểm: Tiêu thụ năng lượng và chi phí đầu tư thấp hơn so với máy nghiền phản lực.

- Nhược điểm: Không thích hợp cho các vật liệu quá cứng hoặc dễ mài mòn do khả năng gây mài mòn.

Máy nghiền tầng sôi đối lưu bằng tia phun: Độ chính xác cao cho vật liệu cứng

Khi độ tinh khiết là yếu tố không thể thiếu và vật liệu cứng (Mohs > 5), ứng dụng máy nghiền khí nén tầng sôi (Fluidized Bed Jet Mill) phát huy tối đa hiệu quả. Trong các hệ thống này, khí nén gia tốc các hạt khiến chúng va chạm với nhau thay vì va chạm với thành máy. Cơ chế tự nghiền này giúp ngăn ngừa ô nhiễm.

- Kích thước mục tiêu: D97 = 1–10 μm.

- Tính năng chính: Thích hợp cho vật liệu pin, gốm sứ và khoáng chất siêu cứng.

- Lợi thế: Không gây ô nhiễm và hao mòn tối thiểu.

Máy nghiền xoắn ốc và đĩa phun: Xử lý nhẹ nhàng

Đối với các sản phẩm có giá trị cao và nhạy cảm với nhiệt như dược phẩm, máy nghiền phản lực cấu trúc đơn giản (xoắn ốc/đĩa) cung cấp môi trường nghiền nhẹ nhàng. Chúng không có các bộ phận chuyển động trong buồng nghiền, giúp việc vệ sinh và khử trùng trở nên vô cùng dễ dàng để tuân thủ tiêu chuẩn GMP.

Hệ thống máy nghiền bi và phân loại khí: Giải pháp công suất cao

Đối với quá trình chế biến khoáng sản công nghiệp quy mô lớn, các máy nghiền đơn lẻ thường thiếu năng suất cần thiết. Hệ thống máy nghiền bi và phân loại khí là tiêu chuẩn cho sản xuất khối lượng lớn. Bằng cách tích hợp bộ phân loại, chúng tôi đảm bảo chỉ có bột mịn thoát ra ngoài trong khi các hạt thô được đưa trở lại máy nghiền. Cấu hình này rất quan trọng đối với các ứng dụng như Khai thác sức mạnh của máy nghiền bi trong quá trình nghiền đá bazan.Trong đó hiệu quả và quy mô là yếu tố tối quan trọng.

Lựa chọn giữa máy nghiền Jet Mill và máy nghiền ACM Mill

Việc biết khi nào nên chuyển từ hệ thống cơ khí sang hệ thống khí nén là rất quan trọng đối với lợi tức đầu tư (ROI).

- Chọn Cơ khí (ACM): Nếu sản phẩm của bạn mềm, chịu nhiệt tốt và yêu cầu D97 > 10 μm.

- Chọn loại dùng khí nén (máy mài tia): Nếu bạn cần kích thước dưới micromet (< 10 μm), đang gia công vật liệu mài mòn hoặc yêu cầu kiểm soát ô nhiễm nghiêm ngặt.

Đối với các nhu cầu chuyên biệt về kích thước dưới micromet, chúng tôi cũng nghiên cứu các lựa chọn tiên tiến như máy nghiền tia hơi nước, sử dụng hơi nước siêu nóng để đạt được động năng cao hơn so với khí nén.

Các tiêu chí đánh giá kỹ thuật và kinh tế thiết yếu

Việc lựa chọn thiết bị nghiền siêu mịn phù hợp không chỉ phụ thuộc vào giá mua ban đầu; mà còn phụ thuộc vào tổng chi phí sở hữu trong suốt vòng đời của máy. Chúng tôi khuyến nghị nên thực hiện đánh giá toàn diện, cân bằng giữa hiệu suất, chi phí vận hành và an toàn.

Hiệu quả năng lượng và chi phí vận hành

Nghiền siêu mịn tiêu tốn nhiều năng lượng. Một máy móc có hiệu suất thấp có thể trông rẻ tiền ban đầu nhưng sẽ làm hao hụt ngân sách của bạn thông qua hóa đơn tiền điện cao. Chúng tôi tập trung vào việc tối ưu hóa trường dòng chảy bên trong máy nghiền để giảm mức tiêu thụ năng lượng kWh/tấn khi nghiền. Bạn nên tính toán chi phí trên mỗi tấn sản phẩm hoàn thiện, bao gồm cả mức tiêu thụ năng lượng và chi phí thay thế các bộ phận hao mòn.

Kiểm soát độ tinh khiết và ô nhiễm

Đối với các ngành công nghiệp như dược phẩm, thực phẩm và vật liệu năng lượng mới, độ tinh khiết là điều không thể thiếu. Xử lý bột không bị nhiễm bẩn là một yêu cầu tiêu chuẩn. Chúng tôi cung cấp các lớp lót chuyên dụng—chẳng hạn như cấu hình thiết bị nghiền siêu mịn GMP bằng gốm, polyurethane (PU) hoặc thép không gỉ—để đảm bảo không có sự nhiễm bẩn sắt. Ví dụ, trong các dự án nhạy cảm cao như của chúng tôi dây chuyền sản xuất xay sữa bộtThiết kế thiết bị ưu tiên vệ sinh và dễ dàng làm sạch để đáp ứng các tiêu chuẩn an toàn thực phẩm nghiêm ngặt.

Các yếu tố đánh giá chính

| Tiêu chuẩn | Tại sao điều đó lại quan trọng | Tiêu chuẩn của chúng tôi |

|---|---|---|

| Kiểm soát quy trình | Sự chính xác quyết định tính nhất quán. | Hệ thống PLC hoàn toàn tự động giúp kiểm soát ổn định sự phân bố kích thước hạt (PSD). |

| An toàn & Môi trường | Bụi là mối nguy hại cho sức khỏe và tiềm ẩn nguy cơ cháy nổ. | Thiết kế áp suất âm để ngăn ngừa rò rỉ bụi; có các tùy chọn thoát khí chống nổ. |

| Dấu chân và tiếng ồn | Không gian là tiền bạc; tiếng ồn ảnh hưởng đến người lao động. | Thiết kế nhỏ gọn với các biện pháp giảm tiếng ồn (<85dB). |

| Khả năng mở rộng | Kết quả thí nghiệm phải khớp với kết quả sản xuất. | Khả năng mở rộng liền mạch từ mô hình phòng thí nghiệm đến mô hình sản xuất công nghiệp. |

Tầm quan trọng của việc mài thử

Đừng bao giờ chỉ dựa vào dữ liệu lý thuyết. Chúng tôi hoạt động theo nguyên tắc “Một khách hàng, một thiết kế”. Trước khi đầu tư, chúng tôi đặc biệt khuyến khích bạn sử dụng dịch vụ nghiền thử nghiệm của chúng tôi. Việc gửi nguyên liệu thô cho phép chúng tôi chứng minh công suất thực tế, độ mịn và tỷ lệ mài mòn, đảm bảo giải pháp phù hợp hoàn hảo với nhu cầu cụ thể của bạn.

Ví dụ ứng dụng thực tế

Lý thuyết thì tốt, nhưng việc quan sát hiệu suất thiết bị trong thực tế mới là yếu tố quyết định. Chúng tôi đã dành hơn 20 năm để thiết kế các giải pháp phù hợp cho từng ngành công nghiệp cụ thể, chứng minh rằng phương pháp "một kích cỡ phù hợp cho tất cả" hiếm khi hiệu quả trong xử lý bột siêu mịn. Dưới đây là cách chúng tôi giải quyết những thách thức khác nhau trong các lĩnh vực khác nhau.

Xử lý dược phẩm nhạy cảm với nhiệt

Khi xử lý việc nghiền các vật liệu nhạy nhiệt, các máy nghiền cơ học tiêu chuẩn thường tạo ra nhiệt lượng quá mức, khiến các thành phần bị tan chảy hoặc phân hủy. Đối với các hoạt chất dược phẩm (API) yêu cầu độ siêu mịn nghiêm ngặt (thường là 1–10 μm), chúng tôi sử dụng máy nghiền tầng sôi dạng tia (Fluidized Bed Jet Mills). Các hệ thống này dựa vào hiệu ứng làm mát của sự giãn nở khí nén để duy trì nhiệt độ bên trong thấp. Điều này đảm bảo tính toàn vẹn hóa học của sản phẩm được giữ nguyên trong khi đạt được sự phân bố kích thước hạt hẹp.

Nghiền các vật liệu siêu cứng dùng trong sản xuất pin

Thị trường xe điện đòi hỏi sự không ô nhiễm. Việc mài các hợp chất lithium mài mòn hoặc vật liệu gốm có thể làm mòn nhanh các bộ phận thép tiêu chuẩn, đưa các tạp chất kim loại vào bột. Để giải quyết vấn đề này, chúng tôi thiết kế các buồng mài của mình với... lớp lót bằng gốm hoặc polyurethaneĐiều này tạo ra môi trường xử lý bột không bị ô nhiễm, rất cần thiết để duy trì sự an toàn và hiệu quả của các vật liệu dùng cho pin.

Xử lý khoáng sản khối lượng lớn

Đối với các khoáng chất phi kim loại như canxi cacbonat, thạch anh hoặc bột talc, ưu tiên thường là năng suất cao và chi phí năng lượng thấp. Trong những trường hợp này, máy nghiền phản lực có thể tiêu tốn quá nhiều năng lượng. Thay vào đó, chúng tôi triển khai hệ thống máy nghiền bi và máy phân loại khí. Các hệ thống quy mô lớn này mang lại sự cân bằng kinh tế tối ưu, cung cấp công suất lớn với mức tiêu thụ năng lượng thấp (kWh/t) đồng thời đảm bảo kiểm soát kích thước hạt chính xác thông qua phân loại tiên tiến.

Hệ thống lớp phủ tích hợp để biến đổi bề mặt

Đạt được kích thước phù hợp chỉ là một nửa chặng đường đối với nhiều ứng dụng. Ngành công nghiệp nhựa và cao su thường cần các chất độn dễ phân tán. Chúng tôi tích hợp thiết bị xử lý bề mặt bột —như máy nghiền Turbo Mill hoặc Pin Mill— trực tiếp vào dây chuyền sản xuất. Điều này cho phép nghiền và phủ đồng thời, cải thiện các đặc tính bề mặt của bột như đá vôi hoặc silica để nâng cao khả năng tương thích với polyme.

Toàn diện của chúng tôi thiết bị nghiền khô Được thiết kế để xử lý các đặc tính vật liệu đa dạng này, đảm bảo rằng dù bạn đang xử lý các chất phụ gia thực phẩm mềm hay gốm sứ cứng như kim cương, sản phẩm đầu ra đều đáp ứng chính xác các thông số kỹ thuật của bạn.

Vì sao thiết kế tùy chỉnh vượt trội hơn so với các giải pháp có sẵn?

Trong lĩnh vực xử lý bột siêu mịn phức tạp, không hề tồn tại khái niệm “máy móc vạn năng”. Mặc dù việc mua một mẫu máy tiêu chuẩn ban đầu có vẻ nhanh hơn, nhưng thiết bị “có sẵn” hiếm khi mang lại hiệu suất tối ưu cho các nhu cầu công nghiệp cụ thể. Chúng tôi hoạt động nghiêm ngặt theo triết lý “Một khách hàng, một thiết kế” bởi vì mỗi loại vật liệu—cho dù đó là khoáng chất cứng hay polyme nhạy nhiệt—đều có những đặc tính riêng biệt quyết định cấu hình của máy.

Những hạn chế của thiết bị thông dụng

Các máy nghiền thông thường buộc dây chuyền sản xuất của bạn phải thỏa hiệp. Một máy tiêu chuẩn có thể đạt được độ mịn mục tiêu nhưng không kiểm soát hiệu quả sự phân bố kích thước hạt (PSD), dẫn đến chất lượng sản phẩm không đồng đều. Thông thường, các thiết bị này tiêu thụ quá nhiều năng lượng hoặc bị mài mòn nhanh chóng vì các bộ phận bên trong (như lớp lót và bánh xe phân loại) không được lựa chọn dựa trên độ mài mòn hoặc độ cứng cụ thể của vật liệu.

Lợi ích của kỹ thuật tùy chỉnh

Việc tùy chỉnh giúp biến dây chuyền chế biến của bạn từ một hoạt động cơ bản thành một hệ thống hiệu quả cao. Bằng cách phân tích hàm lượng độ ẩm, độ dễ vỡ và yêu cầu về độ tinh khiết của nguyên liệu, chúng tôi thiết kế một giải pháp cân bằng giữa năng suất và độ chính xác. Cách tiếp cận được thiết kế riêng này đảm bảo rằng... Máy nghiền siêu mịn đóng vai trò then chốt trong việc thúc đẩy nâng cấp công nghiệp.Điều này cho phép bạn mở rộng quy mô sản xuất mà không làm giảm chất lượng.

So sánh: Giải pháp chung chung so với giải pháp tùy chỉnh

| Tính năng | Thiết bị thông dụng "có sẵn" | Thiết kế tùy chỉnh EPIC |

|---|---|---|

| Kiểm soát kích thước hạt | Không nhất quán; đường cong phân bố rộng | Kiểm soát PSD chính xác; phân bố hẹp |

| Hiệu quả năng lượng | Mức tiêu thụ cao (kWh/t) | Được tối ưu hóa cho tải trọng vật liệu cụ thể |

| Hao mòn | Các bộ phận tiêu chuẩn nhanh chóng bị hao mòn. | Các lớp lót được lựa chọn dựa trên độ cứng của vật liệu. |

| Tích hợp hệ thống | Khó có thể tích hợp vào các dòng sản phẩm hiện có. | Được thiết kế để phù hợp với diện tích cụ thể của bạn. |

Đảm bảo phân bố kích thước hạt (PSD) vượt trội

Mục tiêu tối thượng của việc lựa chọn thiết bị nghiền siêu mịn là độ chính xác. Kỹ thuật tùy chỉnh cho phép chúng tôi tinh chỉnh hệ thống phân loại—điều chỉnh thể tích không khí, áp suất và tốc độ rôto—để đáp ứng chính xác các yêu cầu D97. Cho dù bạn cần kích thước 10 μm cho vật liệu pin hay kích thước dưới micromet cho gốm sứ, một hệ thống được thiết kế chuyên dụng đảm bảo sản lượng của bạn luôn nhất quán giữa các mẻ sản xuất, loại bỏ lãng phí do nghiền quá mức hoặc cặn thô.

Câu hỏi thường gặp về việc lựa chọn máy nghiền

Làm thế nào để xác định loại máy nghiền phù hợp cho các vật liệu nhạy nhiệt?

Nếu vật liệu của bạn có điểm nóng chảy thấp hoặc dễ bị phân hủy dưới tác động nhiệt, các máy nghiền cơ học tiêu chuẩn sẽ tiềm ẩn rủi ro vì chúng tạo ra lượng nhiệt đáng kể trong quá trình va đập. Đối với việc nghiền vật liệu nhạy cảm với nhiệt, chúng tôi hầu như luôn khuyên dùng máy nghiền tầng sôi (Fluidized Bed Jet Mills). Các hệ thống này sử dụng sự giãn nở của không khí nén, giúp làm giảm nhiệt độ bên trong buồng nghiền một cách tự nhiên, giữ cho sản phẩm của bạn luôn mát và bảo toàn tính chất hóa học mà không cần đến các hệ thống làm mát bên ngoài đắt tiền.

Sự khác biệt giữa nghiền siêu mịn khô và nghiền siêu mịn ướt là gì?

Việc lựa chọn giữa nghiền siêu mịn khô và ướt phụ thuộc rất nhiều vào trạng thái sản phẩm cuối cùng và ngân sách năng lượng của bạn.

- Nghiền khô: Thích hợp nhất để sản xuất bột thành phẩm với hàm lượng ẩm thường dưới 4%. Máy tiết kiệm năng lượng vì loại bỏ được quy trình sấy khô tốn kém ở khâu sau. Đây là thế mạnh cốt lõi của chúng tôi, bao gồm mọi thứ từ máy nghiền khí nén đến máy phân loại bi.

- Nghiền ướt: Phương pháp này chủ yếu được sử dụng khi sản phẩm cuối cùng phải ở dạng sệt hoặc khi cần độ mịn ở cấp độ nano mà phương pháp nghiền khô khó đạt được. Tuy nhiên, nó đòi hỏi lượng năng lượng đáng kể để sấy khô sản phẩm trở lại dạng bột.

Độ cứng ảnh hưởng như thế nào đến việc lựa chọn các bộ phận chịu mài mòn?

Độ cứng vật liệu, được đo trên thang Mohs, quyết định trực tiếp tuổi thọ của thiết bị và chi phí thay thế các bộ phận hao mòn. Đối với các khoáng chất mềm (Mohs < 3), thép carbon tiêu chuẩn là đủ. Tuy nhiên, đối với các vật liệu mài mòn như thạch anh hoặc Bột alumina được sử dụng trong các lĩnh vực đánh bóng.Các bộ phận kim loại tiêu chuẩn sẽ bị ăn mòn nhanh chóng và làm ô nhiễm sản phẩm của bạn. Trong những trường hợp này, chúng tôi thiết kế máy móc với khả năng tương thích với máy nghiền có độ cứng Mohs, sử dụng lớp lót bằng gốm, cacbua vonfram hoặc polyurethane để đảm bảo độ bền và độ tinh khiết.

Một máy có thể xử lý nhiều loại vật liệu khác nhau không?

Mặc dù nhiều máy nghiền của chúng tôi cung cấp các thông số điều chỉnh để kiểm soát phân bố kích thước hạt (PSD), nhưng việc sử dụng một máy duy nhất cho các vật liệu rất khác nhau không phải lúc nào cũng lý tưởng do sự đánh đổi giữa việc làm sạch và hiệu quả.

- Lây nhiễm chéo: Việc chuyển đổi từ than đen sang bột dược phẩm trắng đòi hỏi thiết kế máy nghiền đạt tiêu chuẩn GMP bằng thép không gỉ, dễ tháo lắp và vệ sinh.

- Hiệu quả: Máy móc được tối ưu hóa cho gốm cứng có thể không tiết kiệm năng lượng khi gia công polyme mềm.

Chúng tôi theo đuổi phương pháp “Một khách hàng, một thiết kế”. Mặc dù một máy nghiền phân loại khí nén dành cho bột siêu mịn có thể được điều chỉnh, nhưng một giải pháp tùy chỉnh đảm bảo bạn không phải hy sinh năng suất hoặc chất lượng chỉ để có một máy “đa năng”.

Cảm ơn bạn đã đọc. Tôi hy vọng bài viết của tôi hữu ích. Vui lòng để lại bình luận bên dưới. Bạn cũng có thể liên hệ với bộ phận chăm sóc khách hàng trực tuyến của Zelda nếu có bất kỳ thắc mắc nào khác.

— Đăng bởi Emily Chen