Cao lanh, thường được gọi là "khoáng chất đa năng", là một loại khoáng sét chủ yếu gồm kaolinit. Nó nổi tiếng với độ trắng cao, độ dẻo tuyệt vời, khả năng chịu nhiệt cao và độ ổn định hóa học vượt trội. Cao lanh được sử dụng rộng rãi trong ngành giấy, gốm sứ, sơn phủ, cao su, nhựa, dược phẩm và thậm chí cả công nghiệp quốc phòng.

Tuy nhiên, giá trị thực sự của cao lanh phụ thuộc phần lớn vào độ mịn của bột, sự phân bố kích thước hạt, hình thái hạt và độ tinh khiết của nó. Việc đạt được những đặc tính vượt trội này phụ thuộc rất nhiều vào thiết bị nghiền tiên tiến. Hiện đại nghiền siêu mịn Các công nghệ này không chỉ giúp giảm kích thước hạt cao lanh xuống mức micron hoặc thậm chí dưới micron, mà còn tối ưu hóa các đặc tính lý hóa của nó, làm tăng đáng kể giá trị gia tăng của sản phẩm.

Ảnh hưởng quyết định của độ mịn nghiền đến hiệu suất của cao lanh

Hạt cao lanh càng mịn thì diện tích bề mặt riêng càng lớn và hoạt tính bề mặt càng cao. Điều này trực tiếp làm tăng cường một số đặc tính quan trọng:

- Màu trắng và khả năng che giấuBột siêu mịn với hàm lượng TP3T trên 80% dưới 2 μm có thể đạt độ trắng trên 95%. Chúng được sử dụng rộng rãi trong lớp phủ giấy và sơn cao cấp, giúp cải thiện độ bóng của giấy và khả năng hấp thụ mực.

- Độ dẻo và độ bền liên kếtCác hạt mịn giúp tăng cường liên kết giữa các hạt, cải thiện khả năng tạo hình và độ bền khô của vật liệu gốm.

- Khả năng phân tán và độ ổn định huyền phùCao lanh dễ dàng tạo thành huyền phù ổn định trong nước, do đó rất thích hợp để làm chất phủ và chất độn cao su.

- Khả năng chịu nhiệt và tính ổn định hóa họcSau khi nghiền mịn, nhiệt độ thiêu kết trở nên dễ kiểm soát hơn, với độ chịu nhiệt đạt 1770–1790°C.

- Khả năng hấp phụ và khả năng trao đổi cationTăng diện tích bề mặt riêng giúp cải thiện hiệu suất trong các ứng dụng xúc tác và môi trường.

Phương pháp nghiền thô truyền thống không thể đáp ứng được những yêu cầu này. Ngược lại, thiết bị nghiền tiên tiến cho phép kiểm soát chính xác sự phân bố kích thước hạt, biến cao lanh từ một chất độn thông thường thành một vật liệu chức năng cao cấp.

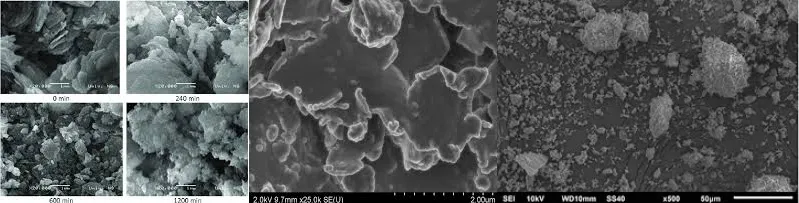

(Hình ảnh SEM phía trên cho thấy bột cao lanh siêu mịn với các hạt dạng tấm đều đặn, bề mặt nhẵn và phân bố đồng đều - một nền tảng thiết yếu cho các ứng dụng cao cấp.)

Các loại thiết bị nghiền tiên tiến và hiệu quả tối ưu hóa của chúng đối với cao lanh.

Hiện nay, các thiết bị nghiền cao lanh phổ biến bao gồm máy nghiền đứng siêu mịn, máy nghiền trục lăn, máy nghiền tia, máy nghiền khuấy và máy nghiền va đập cơ học tốc độ cao. Mỗi loại đều có ưu điểm riêng và có thể được ứng dụng trong quá trình chế biến siêu mịn khô hoặc ướt đối với các loại cao lanh khác nhau (cao lanh cứng, mềm và cát).

| Loại thiết bị | Độ mịn điển hình của sản phẩm (μm) | Công suất (t/h) | Ưu điểm chính | Nâng cao hiệu suất của cao lanh |

|---|---|---|---|---|

| Máy nghiền đứng siêu mịn (ví dụ: dòng GKLMX, CLUM) | 3–45 | 3–45 | Tích hợp quá trình nghiền, phân loại và vận chuyển; tiết kiệm năng lượng. | Phân bố kích thước hẹp, độ trắng cao, sản xuất quy mô lớn |

| Máy nghiền trục vòng (ví dụ: dòng HCH, HGM) | 5–74 | 1–22 | Cán nhiều lớp, độ cầu hóa cao. | Khả năng phân tán và độ dẻo được cải thiện; lý tưởng cho các lớp phủ. |

| Máy nghiền phản lực (lò hơi nước hoặc lò khí quyển) | 1–30 | 0,5–10 | Không bị lẫn tạp chất trong vật liệu mài; hình dạng hạt đồng đều. | Độ tinh khiết cao và hoạt tính cao; thích hợp để tráng phủ giấy. |

| Máy nghiền khuấy (nghiền ướt theo chiều dọc) | 1–10 | 1–15 | Mài vật liệu với hiệu quả tách lớp tuyệt vời | Giữ nguyên cấu trúc dạng tấm; tăng cường khả năng che giấu và hấp phụ. |

| Cơ khí tốc độ cao máy nghiền va đập | 3–74 | 2–20 | Máy nghiền va đập hiệu quả cao | Giảm kích thước nhanh chóng kết hợp với loại bỏ tạp chất |

Các hệ thống này thường được trang bị bộ phân loại độ chính xác cao (như bộ phân loại turbo) để đảm bảo phân bố kích thước hạt hẹp. Hoạt động ở áp suất âm và thu gom bụi bằng xung giúp sản xuất sạch sẽ và thân thiện với môi trường, đáp ứng đầy đủ các tiêu chuẩn môi trường hiện đại.

Ứng dụng thực tiễn và triển vọng tương lai

Trong ngành công nghiệp giấy, cao lanh được xử lý bằng máy nghiền khí nén với kích thước hạt dưới 2 μm có thể làm tăng độ bóng của giấy tráng phủ lên hơn 30%. Trong ngành gốm sứ, cao lanh tách lớp được sản xuất bằng máy nghiền khuấy giúp cải thiện độ bền của vật liệu thô và độ đồng đều khi nung kết. Trong ngành sơn phủ và nhựa, các sản phẩm từ máy nghiền đứng siêu mịn giúp tăng cường khả năng che phủ và khả năng chống mài mòn.

Khi nhu cầu thị trường tăng cao đối với các sản phẩm “đạt chuẩn 90 kép” (độ trắng ≥ 90% và hàm lượng hạt −2 μm ≥ 90%), thiết bị nghiền tiên tiến đang thúc đẩy sự chuyển đổi của cao lanh từ nguyên liệu thô có giá trị thấp thành vật liệu chức năng có giá trị cao.

Trong tương lai, kết hợp với công nghệ điều khiển thông minh dựa trên trí tuệ nhân tạo và công nghệ biến đổi bề mặt, hiệu suất của cao lanh sẽ tiếp tục được nâng cao, mở rộng sang các lĩnh vực mới nổi như pin năng lượng mới và hấp phụ môi trường.

Phần kết luận

Thiết bị nghiền tiên tiến không chỉ đơn thuần là công cụ xử lý cao lanh mà còn là yếu tố then chốt giúp mang lại hiệu suất vượt trội cho sản phẩm. Việc lựa chọn giải pháp nghiền phù hợp có thể cải thiện đáng kể chất lượng sản phẩm, giảm tiêu thụ năng lượng và nâng cao khả năng cạnh tranh trên thị trường, từ đó đạt được hiệu quả sử dụng tài nguyên và phát triển bền vững.

Cảm ơn bạn đã đọc. Tôi hy vọng bài viết của tôi hữu ích. Vui lòng để lại bình luận bên dưới. Bạn cũng có thể liên hệ với bộ phận chăm sóc khách hàng trực tuyến của Zelda nếu có bất kỳ thắc mắc nào khác.

— Đăng bởi Emily Chen