Thông tin khách hàng

Khách hàng là một nhà cung cấp hàng đầu của Úc về gốm sứ tiên tiến và vật liệu dẫn nhiệt. Nghiền siêu mịn alumina là rất quan trọng đối với ứng dụng này, vì sự phân bố kích thước hạt alumina quyết định trực tiếp đến mật độ thiêu kết và độ bền cơ học của các sản phẩm cuối cùng như chất nền gốm, dung dịch đánh bóng chính xác và chất độn dẫn nhiệt.

Yêu cầu cốt lõi

- Độ mịn cực cao: Kích thước hạt mục tiêu phải đạt được D97: 2,07 μm, tiến vào phạm vi xử lý dưới micromet.

- Bảo vệ độ tinh khiết cao: Nhôm oxit có độ cứng cực cao (độ cứng Mohs là 9). Trong quá trình gia công, việc ngăn ngừa ô nhiễm kim loại do mài mòn thiết bị là rất cần thiết.

- Kiểm soát chặt chẽ các hạt thô: Các hạt lớn hơn 5 μm Tuyệt đối không được phép sử dụng chúng, vì chúng có thể gây trầy xước hoặc hư hỏng trong quá trình sử dụng.

Giải pháp: Bột Epic Tận tụy Phay tia nước Hệ thống

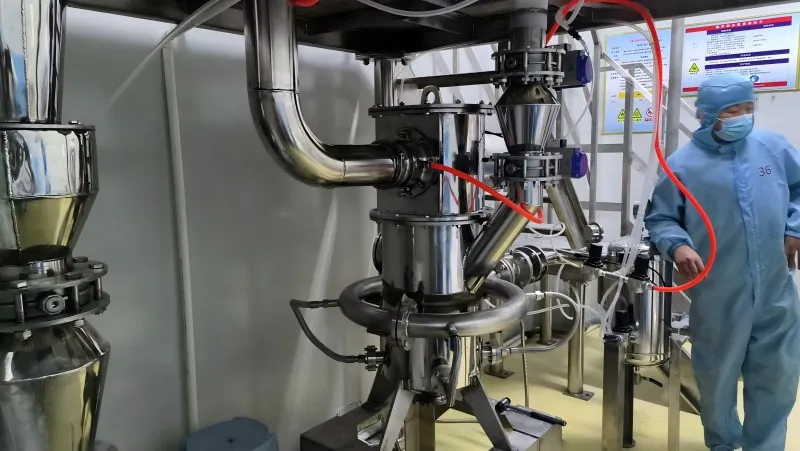

Để đáp ứng các yêu cầu về độ cứng và độ tinh khiết cao của alumina, Epic Powder đã cung cấp giải pháp hệ thống máy nghiền tầng sôi MQW Series tùy chỉnh.

1. Cấu hình kỹ thuật mục tiêu

- Lớp phủ gốm bảo vệ toàn diện: Để chịu được độ mài mòn mạnh của alumina, các thành bên trong của buồng nghiền, vòi phun và lưỡi phân loại đều được làm bằng gốm alumina hoặc cacbua silic. Điều này không chỉ kéo dài đáng kể tuổi thọ thiết bị mà còn đảm bảo... không có tạp chất kim loại trong quá trình xử lý.

- Mài bằng luồng khí siêu âm: Sử dụng 3-4 vòi phun Laval để tạo ra luồng khí siêu âm, các hạt alumina trải qua các va chạm mạnh tại vùng hội tụ của luồng khí. Nguyên lý mài mòn "hạt trên hạt" này giúp giảm đáng kể sự mài mòn trên các bộ phận thiết bị.

- Phân loại chính xác tốc độ cao: Được trang bị bánh xe phân loại ngang tốc độ cao thế hệ mới nhất. Thông qua điều khiển tần số biến đổi, điểm cắt được điều chỉnh chính xác để đảm bảo D97 được duy trì ổn định ở mức 2,07 μm.

2. Dữ liệu thử nghiệm và sản xuất cho dây chuyền nghiền siêu mịn alumina

| Tham số | Kết quả thử nghiệm / sản xuất |

|---|---|

| Vật liệu đã qua xử lý | Bột alumina nung |

| Kích thước hạt sản phẩm (D97) | 2,07 μm |

| Phân bố kích thước hạt | Phân bố hẹp điển hình với một đỉnh duy nhất |

| Tăng lượng tạp chất (Fe) | < 5 ppm (hầu như không tăng) |

| Kích thước hạt nguyên liệu | 150 lưới |