Basalt, a fundamental volcanic rock, forms a significant part of the Earth’s oceanic crust and the Moon’s lunar seas, as well as being an essential component of the Earth’s continental crust and the Moon’s lunar surface. Thanks to its high hardness, density, impressive compressive strength, wear resistance, low water absorption, and corrosion resistance, basalt is commonly used in the production of stone materials for highways. Basalt grinding processes further enhance its usability in various construction and industrial applications.

Various Properties and Applications of Basalt

Construction Industry: Basalt is ideal for building walls, floors, stairs, and other structures due to its hardness and high density. It is widely recognized for its aesthetic appeal, durability, and low maintenance.

Roads and Bridges: Basalt is commonly used in road paving and bridge construction because of its excellent wear resistance and high density. It extends the lifespan of roads and bridges through its durability and compressive strength.

Water Conservancy Engineering: Basalt’s resistance to corrosion makes it perfect for water conservancy projects like dams, sluices, and pump houses. Its high density and durability ensure the safety and stability of these projects.

Thermal Insulation, Temperature Resistance, and Fireproof Fields: Basalt fibers, known for their high-temperature resistance, are used in firefighting applications, high-temperature filtration, dust removal, and thermal insulation materials.

Automotive Industry: Due to its stable friction coefficient, basalt fibers are used in friction-enhancing materials like brake pads. They are also used for noise reduction in automotive interiors due to their high sound absorption properties.

Petrochemical Industry: The corrosion resistance of basalt fibers is particularly advantageous in the petrochemical industry. They are combined with epoxy resin to create wound high-pressure pipes that provide thermal insulation and corrosion resistance.

Advantages of Ball Mill in Basalt Grinding

High Grinding Efficiency: Ball mills offer higher grinding efficiency than vertical mills. Although energy consumption is higher, ball mills are ideal for large-scale production with continuous production needs.

Stable Product Quality: Ball mills minimize material residence time, reducing repetitive grinding. This results in uniform particle shapes and narrow particle size distributions, ensuring consistent product quality.

Low Noise and Environmental Protection: Ball mills use a sealed negative pressure system, minimizing dust leakage during operation and reducing health risks for workers.

High Reliability: Ball mills feature roller limiters and sealing systems for dual protection. This minimizes excessive vibrations and ensures stable operation.

High Automation: With advanced PLC control systems, ball mills enable remote monitoring and easy operation, enhancing automation levels in production.

Low Operating Costs: The roller assembly can be easily lifted out for maintenance using a hydraulic device. Reversible roller sleeves prolong the service life, reducing replacement costs.

Strong Drying Capacity: Ball mills can pass hot air through the material, handling raw materials with moisture content up to 15%, eliminating the need for separate dryers and saving energy.

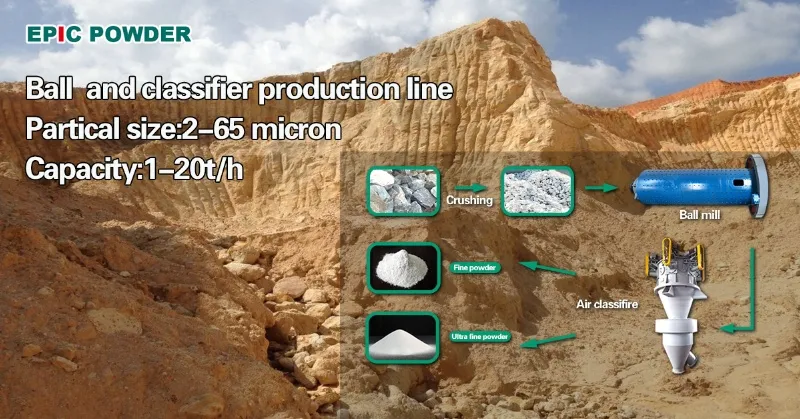

Low Overall Investment Costs: Ball mills integrate crushing, grinding, classification, and transportation in one machine. Their compact structure and small footprint make them cost-effective for both construction and equipment investments.

epic powder

Epic Powder, with years of experience in powder processing, offers cutting-edge solutions for basalt grinding. With a focus on efficiency and quality, our ball mills deliver reliable, high-performance results for large-scale production. Whether for construction, or industrial applications, Epic Powder is your trusted partner for all your grinding needs.