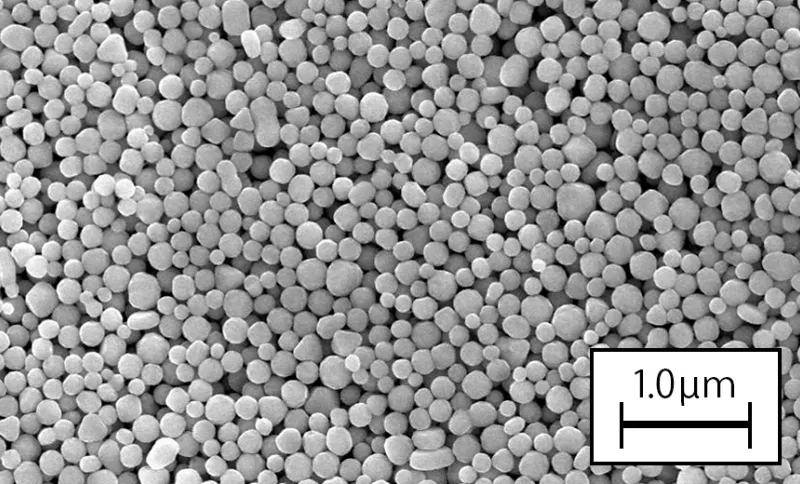

Ultrafine nickel powder generally refers to nickel powder with a particle size of less than 1 μm. According to particle size, ultrafine nickel powder is usually divided into micron-grade nickel powder (average particle size ≥ 1 μm), submicron-grade nickel powder (average particle size 0.1–1.0 μm), and nano-grade nickel powder (average particle size 0.001–0.100 μm).

It features small particle size, high surface activity, good electrical conductivity, and excellent magnetic properties. It is widely used in hard alloys, multilayer ceramic capacitors (MLCCs), magnetic materials, high-efficiency catalysts, conductive pastes, wave-absorbing materials, and electromagnetic shielding materials.

Many industries have high requirements for the purity, dispersibility, and sphericity of nickel powder. Producing spherical ultrafine nickel powder with high sphericity, high purity, and good dispersibility has become a research focus in the field of nickel powder preparation.

Due to its high specific surface area, excellent conductivity, catalytic activity, and magnetic properties, ultrafine nickel powder is widely applied in many high-tech and industrial fields.

Electronics and Semiconductor Field

Multilayer Ceramic Capacitors (MLCCs): Ultrafine nickel powder is a key material for MLCC internal electrodes. It can replace traditional precious metal palladium/silver alloys. This greatly reduces manufacturing costs while meeting the needs of high-frequency and miniaturized electronic components.

Conductive Pastes and Packaging: Its high conductivity and dispersibility make it suitable for electronic pastes and conductive coatings on printed circuit boards (PCBs). These improve the conductivity and heat dissipation of electronic devices.

Semiconductor Materials: It is used as conductive filler in chip packaging. This enhances the thermal conductivity and mechanical stability of the materials.

Energy Storage and Conversion

Lithium-ion Batteries: Used as a cathode material (such as LiNiO₂), it significantly increases energy density and cycle life. This is particularly valuable for electric vehicles and energy storage systems.

Fuel Cells: Acts as a catalyst (e.g., hydrogen-oxygen reaction catalyst). It improves reaction efficiency, reduces platinum usage, and lowers costs.

Supercapacitors: Nano-structural optimization enhances the charge storage capacity of electrode materials.

Catalysis and Environmental Protection

Petrochemicals: Serves as a high-efficiency catalyst for hydrogenation and dehydrogenation reactions. It increases yield and product purity, such as in toluene hydrogenation to produce methylcyclohexane.

Environmental Protection: Used in waste gas and wastewater treatment. It catalyzes the degradation of pollutants and reduces harmful emissions.

New Energy Catalysis: Plays a role in hydrogen production via steam methane reforming (SMR). This promotes the development of clean energy.

Magnetic Materials and Wave-Absorbing Technology

Magnetic Fluids and Storage Media: Dispersed in carrier liquids to form magnetic fluids. Also used in high-density magnetic storage devices such as quantum disks.

Electromagnetic Shielding and Wave-Absorbing Materials: Ultrafine nickel powder has excellent electromagnetic properties. When combined with polymer matrices, it forms electromagnetic shielding materials. Copper-nickel composites perform well in high-frequency absorption and shielding. These materials are used in stealth technology and civilian electronics. Conductive coatings based on ultrafine nickel powder are widely applied in military stealth and electronic devices.

Aerospace and Advanced Manufacturing

High-Temperature Alloys: Added to improve high-temperature resistance and corrosion resistance of alloys. Suitable for aerospace engine components.

Hard Alloys: Can replace cobalt as a binder metal in cutting tools and wear-resistant parts. This reduces cost and improves performance.

Biomedicine and New Materials

Pharmaceutical Carriers and Diagnosis: Magnetic responsiveness and biocompatibility enable targeted drug delivery and magnetic labeling detection.

3D Printing and Composites: Serves as filler for metal injection molding (MIM). This improves the mechanical properties and forming accuracy of complex parts.

Epic powder

In conclusion, the remarkable properties of ultrafine nickel powder have unlocked vast potential across electronics, energy storage, catalysis, environmental protection, and advanced manufacturing. Meeting the strict requirements for particle size, sphericity, purity, and dispersibility demands precision engineering and reliable processing technology. Epic Powder, with its advanced grinding, classification, and surface modification equipment, provides tailored solutions to produce high-quality ultrafine nickel powder. By ensuring consistent particle control and optimal performance, Epic Powder empowers industries to fully harness the advantages of ultrafine nickel powder in cutting-edge applications.