Silica micro-powder, as a typical inorganic filler, possesses excellent properties, including:

- “Three Highs” (High insulation, high thermal conductivity, high thermal stability);

- “Three Lows” (Low thermal expansion coefficient, low dielectric constant, low raw material cost);

- “Two Resistances” (Acid and alkali resistance, wear resistance). These features make silica micro-powder widely used and highly regarded.

During the ultra-fine grinding process, the specific surface area of silica micro-powder increases continuously. As a result, large amounts of hydroxyl groups (-OH) are exposed on the surface, enhancing its polarity. This results in higher surface energy, and due to the presence of electrostatic forces, the particles tend to agglomerate and are difficult to disperse. Moreover, the presence of hydroxyl groups on the surface also makes it hydrophilic, which hinders its dispersion in organic polymer media. Therefore, surface modification of silica micropowder is necessary.

Coating Modification

Coating modification primarily involves utilizing the functional groups on the surface of silica micro-powder and high polymer materials to coat the powder. After the coating modification process, an organic polymer thin film forms on the silica micro-powder surface. This “film” modifies the surface of the silica micropowder.

There are two main methods for surface coating: cold modification and hot modification. To ensure effective modification, silica micro-powder should first undergo cleaning and drying treatment before the coating process.

Cold Modification

This process is carried out at room temperature. First, epoxy resin is thoroughly mixed with silica micro-powder. Then, organic solvents required for modification are added. During the mixing process, the solvent gradually evaporates until it completely disappears. The modified product is then obtained through filtration and drying. Cold modification requires a large amount of organic solvents, which makes it difficult to scale up for industrial production. The cost is high, and the modification efficiency is low.

Hot Modification

In this method, silica micro-powder is pretreated by heating it to 120-140°C, then mixed with resin. The resin typically accounts for 2%-5% of the silica micro-powder’s mass. The heat softens the resin, which then coats the silica micropowder surface. As the temperature decreases, the resin becomes sticky and adheres to the surface. A curing agent (such as urotropine) and calcium stearate are added, and the mixture is thoroughly mixed to prevent agglomeration of the silica micro-powder. After cooling and sieving, the modified silica micropowder is obtained. This method provides better coating effects and is suitable for mass production, but the process is more complex and difficult to control.

Dry Modification

Compared to coating modification, dry modification is more widely used in powder surface modification. The powder to be modified is added to a high-speed blender. Depending on the type of powder, the blender is heated to a different temperature. A pre-mixed modifier is then added to the blender to complete the surface modification.

Dry modification offers a simple process and low production costs. It is currently the primary method for surface modification of silica micropowders in China and is suitable for micron-sized silica micropowders.

Wet Modification

Wet modification involves wetting the surface of silica micro-powder in a liquid phase to reduce surface bonding energy. Surface modifiers and additives are then added, and the mixture is stirred and dispersed at a certain temperature to achieve surface modification. Wet modification allows the silica micropowder to disperse more easily and combine more fully with the modifier. The modification is more uniform, but the process is complex and energy-intensive, making it more suitable for ultra-fine silica micro-powder with a particle size of less than 5μm. Furthermore, the water solubility of the modifier must be considered, as only water-soluble modifiers will disperse better and interact effectively with the Si—OH groups on the silica surface.

Composite Modification Process

Composite modification refers to the process where modifiers are added during the fine grinding process, integrating powder grinding and modification in one step. The composite modification process is relatively simple, easy to operate, and can improve grinding and modification efficiency because the presence of modifiers enhances the grinding ability of the grinding media.

When selecting modifiers, their structure, properties, modification mechanisms, and the properties of the base material being filled must all be considered.

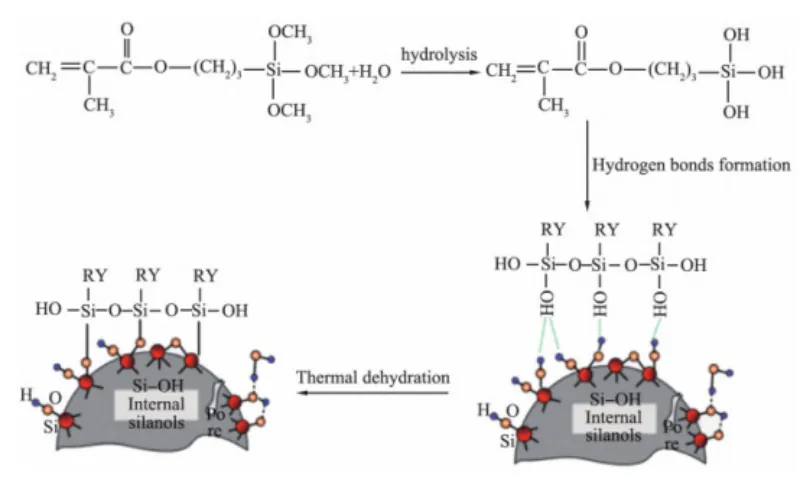

The most commonly used modifiers in silica micro-powder surface modification are silane coupling agents. These are low-molecular-weight organosilicon compounds that contain two or more chemically distinct groups. Their molecular structure includes functional groups (such as amino, vinyl, or epoxy groups) that interact with organic polymers, as well as alkoxy groups that can hydrolyze and interact with the silica micro-powder surface. This allows the silica micropowder to bond tightly with organic polymers.

Epic Powder

Epic Powder’s advanced grinding and coating equipment plays a key role in the processing and surface modification of silica micro-powder. By utilizing high-efficiency grinding technologies such as ball mills and air classifiers, Epic Powder ensures that silica micropowder is precisely processed to achieve the desired particle size and surface characteristics. The integration of surface modification with fine grinding further enhances the material’s performance and dispersibility in various applications. As the demand for higher performance materials continues to grow, Epic Powder’s reliable equipment and tailored solutions will be essential in optimizing silica micro-powder production for a wide range of industries.