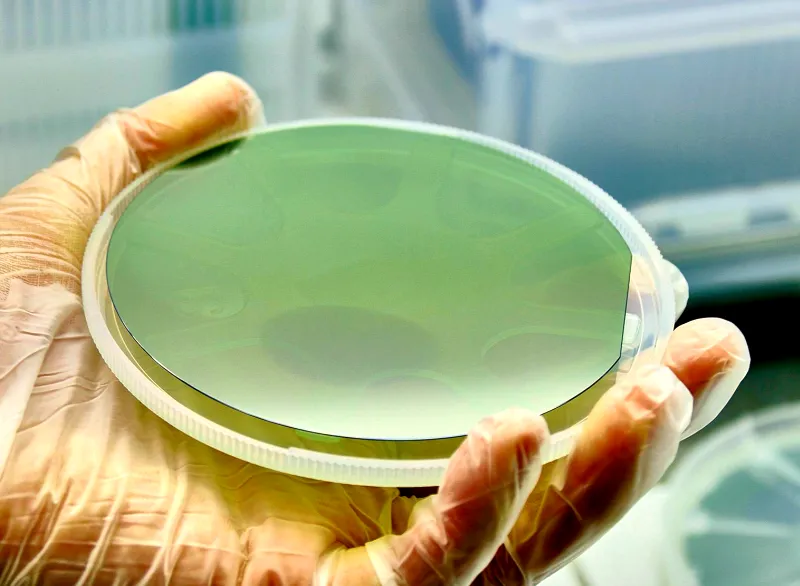

Silicon carbide (SiC) is a wide-bandgap semiconductor with unique physical properties. It offers high bandgap width, strong breakdown electric field, excellent thermal conductivity, and fast electron saturation drift rate. These characteristics allow SiC to perform reliably in extreme conditions such as high temperature, high voltage, high power, and high frequency. Today, silicon carbide has become essential in power electronics, new energy vehicles, energy storage, intelligent manufacturing, photovoltaics, rail transit, and more. It is no exaggeration to say that “everything can be silicon carbide.”

Silicon Carbide in New Energy Vehicles

Silicon carbide (SiC) is a wide-bandgap semiconductor with unique physical properties. It offers high bandgap width, strong breakdown electric field, excellent thermal conductivity, and fast electron saturation drift rate. These characteristics allow SiC to perform reliably in extreme conditions such as high temperature, high voltage, high power, and high frequency. Today, silicon carbide has become essential in power electronics, new energy vehicles, energy storage, intelligent manufacturing, photovoltaics, rail transit, and more. It is no exaggeration to say that “everything can be silicon carbide.”

SiC in New Energy Vehicles

In electric and hybrid vehicles, SiC devices are key to performance improvement. Their high thermal conductivity and strong breakdown field enhance efficiency and reliability. SiC is widely used in drive systems, charging systems, and energy management systems.

SiC in Intelligent Driving and IoV

With intelligent driving and the Internet of Vehicles (IoV) rapidly evolving, SiC technology is penetrating core systems. It is applied in sensors, data processors, and communication modules. These advantages significantly boost reliability and overall system performance.

SiC in Photovoltaic Systems

Photovoltaic systems demand efficiency, high-voltage resistance, high-temperature tolerance, and miniaturization. Inverters, MPPT controllers, and energy storage modules all rely on power devices. Traditional silicon devices degrade under high temperature and voltage, limiting efficiency. SiC, with its superior properties, solves these issues and meets rising power density requirements in solar power plants.

SiC in 5G Communications

5G networks and radar systems depend on RF devices. These components handle signal transmission and processing, directly influencing stability. RF devices built on semi-insulating SiC provide low loss, high bandwidth, and high power density. They have become vital for next-generation 5G and advanced military communication systems.

SiC in Power Grids

Power grids benefit greatly from SiC. SiC devices improve efficiency and capacity in transmission and distribution. They also enable converters, switchgear, and transformers to operate at higher voltages, frequencies, and temperatures. This leads to smaller, more efficient components with reduced energy loss and improved power quality.

SiC in Low-Altitude Aircraft

The eVTOL (electric vertical take-off and landing) market is booming within the low-altitude economy. SiC MOSFETs are core to eVTOL power systems. Their high efficiency and lightweight design push aircraft from testing into real-world commercial operation. Lower costs and better performance will accelerate large-scale adoption in this trillion-dollar industry.

SiC in Artificial Intelligence

AI requires massive computing power, which drives up electricity demand. U.S. data centers alone may consume 9% of national power generation by 2030. This equals the annual output of about 40 nuclear power plants.

Even a 0.1% reduction in energy use is significant. SiC devices, including MOSFETs, are being developed to improve energy efficiency. For example, ON Semiconductor has created a new generation of SiC-based trench power MOSFETs to help address this challenge.

SiC in Robotics

Robotics shares many technologies with new energy vehicles. Automotive-grade power chips are adaptable for robots, though performance needs differ. SiC-based power semiconductors provide efficient motor drive control for robotic joints. This market is growing quickly as demand for precision and efficiency increases.

Epic Powder

As demand for high-performance materials rises, silicon carbide powder preparation becomes increasingly important. Epic Powder, with more than 20 years of expertise in grinding, classification, and surface modification, provides advanced solutions for SiC ultrafine processing. Through precise particle size control and powder engineering, Epic Powder helps unleash the full potential of silicon carbide across energy, electronics, aerospace, and intelligent manufacturing industries.