Silicon-based anode electrode materials are the most promising high-capacity materials in the current lithium-ion battery field. They are mainly divided into two main technical routes: silicon-oxygen negative electrodes and silicon-carbon negative electrodes. Compared with traditional graphite negative electrodes (theoretical specific capacity of 372 mAh/g), silicon-based negative electrodes have a significantly higher theoretical specific capacity. Pure silicon has a capacity of 4200 mAh/g, while silicon dioxide has about 1500-1600 mAh/g. This can greatly improve battery energy density and meet the high-energy battery needs of electric vehicles and energy storage systems.

Silicon Oxide Anode (SiOx)

The material is mainly composed of silicon suboxide (0<x<2) and carbon composites. It has several advantages, including relatively small volume expansion (about 150%) and good cycling stability. However, its initial efficiency is lower, ranging from 70% to 92%. Based on different pre-doped elements, silicon-oxygen negative electrodes can be divided into three generations. These are the first generation of ordinary silicon-oxygen negative electrodes, the second generation of magnesium-doped silicon-oxygen negative electrodes, and the third generation of lithium-doped silicon-oxygen negative electrodes.

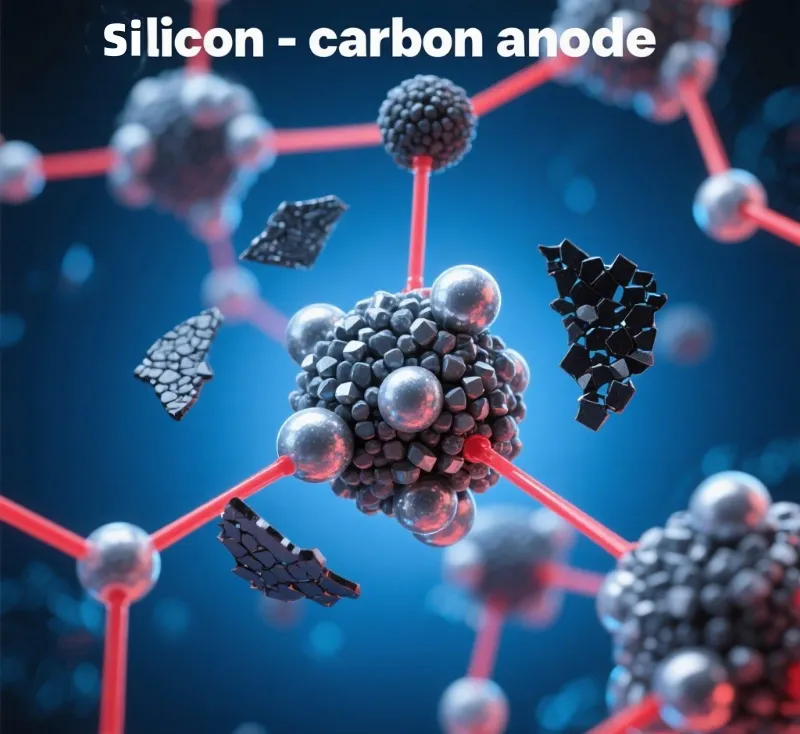

Silicon-carbon negative electrodes

Silicon-carbon negative electrodes are made by combining nano-silicon particles with carbon-based materials such as graphite, carbon nanotubes, and graphene. They offer higher specific capacity and initial efficiency. However, their cycling performance and expansion issues are more pronounced.

development prospects

From an industrialization perspective, leading companies have largely addressed issues like the expansion rate of silicon-carbon negative electrodes by 2023-2024. The industrialization of silicon-based anode electrode materials is accelerating. Companies like CATL have already started equipping next-generation high-energy density cells, such as their condensed-state cells, with silicon-carbon negative electrodes. The continuous development of high-performance cells further solidifies their industry leadership. Market forecasts show that the global demand for nano-silicon powder for silicon-based negative electrodes will be around 3,786 tons in 2023. By 2025, this demand is expected to reach 24,000 tons, with a compound annual growth rate of 110.1%.

The production process of silicon-based anode electrode materials are complex. It mainly includes key steps such as nano-silicon powder preparation, composite precursor preparation, carbon coating treatment, and post-processing. The mainstream preparation techniques vary depending on the composite method and process route. These include chemical vapor deposition (CVD), sol-gel method, high-temperature pyrolysis, and mechanical ball mill. Each method has its own characteristics. They are suitable for the production of different types of silicon-based negative electrodes.

Epic powder

In conclusion, EPIC Powder is at the forefront of advancing the production of silicon-based anode materials. With expertise in processing nano-silicon powders, composite precursors, and carbon coating treatments, EPIC Powder is well-equipped to support the growing demand for high-performance battery materials. As the industry continues to evolve, EPIC Powder’s innovative solutions play a key role in enhancing energy density and cycling stability, contributing to the development of next-generation lithium-ion batteries for electric vehicles and energy storage systems.