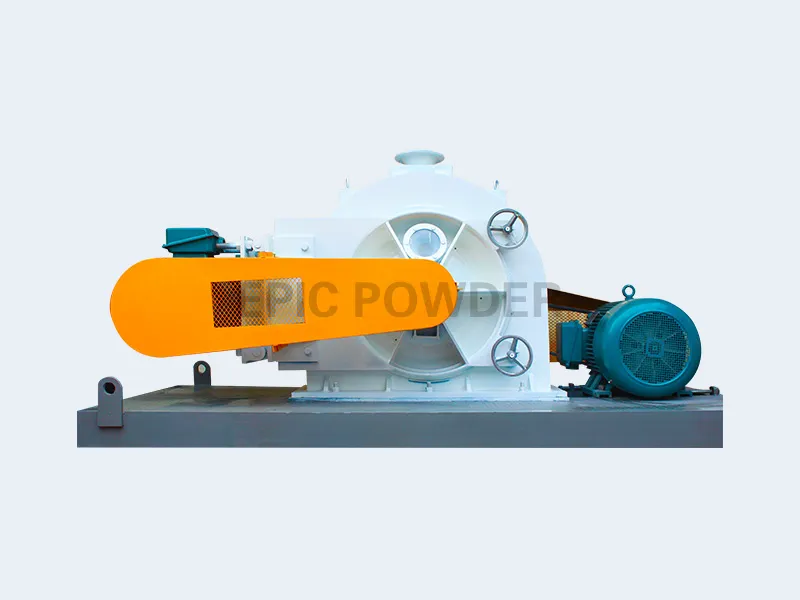

Turbo Mill Coating Machine

EPIC Powder combines advanced powder modification technology at home and abroad, and independently developed UCOAT series continuous modification equipment. The modification rate of vortex mill coating machine is up to 99%, and the product quality is stable.

- Turbo mill coating machine is composed of frame, body, stator, rotor, filling hopper, bearing seat and motor. The Turbo mill coating machine has the features of high rotational speed, long service life, convenient maintenance and high crushing efficiency.

- Heavy calcium carbonate is a kind of energy-saving, green and environmental protection mineral material. Due to its special physical and chemical properties, as well as its low price and wide sources, it has become one of the main modified powders of Turbo mill coating machine.

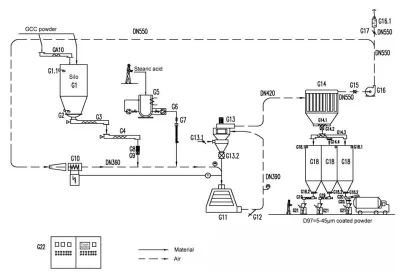

Working Principle

The mineral powder is fed from the top of the modifier, pre-crushed by the upper cover of the rotor and then thrown into the main machine. The material enters the comminution zone between the stator and the rotor. The conical crushing area creates ventilation conditions between the rotor and stator.

Under the combined effect of centrifugal force and suction, the right amount of material impacts the edge of the blade at high speed and there is a fierce collision between the material and the material. Through this repeated impact, collision, the material can achieve the purpose of ultrafine grinding.

Features of coated calcium carbonate powder

Coated calcium carbonate, also known as active calcium carbonate, is the main finished product of the Turbo mill coating machine. So what are the characteristics of the coated calcium carbonate powder?

The appearance of coated calcium carbonate is white powder, which is non-toxic, tasteless, non-irritating, non-flammable, non-explosive, low refractive index, easy to color, insoluble in water, and stable in the air.

The modified calcium carbonate has better lubricity, fluidity and organic properties than before modification. Modified calcium carbonate has the features of good gloss, uniform dispersion, and large filling capacity.

Coated calcium carbonate powder has strong intermolecular affinity with rubber and plastic, and the filling amount is 2-5 times that of ordinary calcium carbonate.

Coated calcium carbonate has superb metal stripping and remarkable lubricating effect, and also improves the surface brightness, anti-wear and anti-impact strength of products.

Features of coated calcium carbonate powder

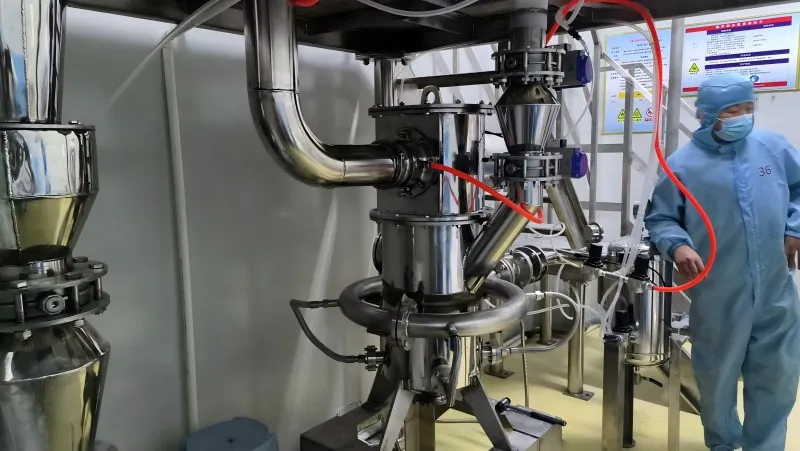

The Turbo mill powder coating machine has good surface modification effect on heavy calcium carbonate, light calcium carbonate, kaolin, talc, wollastonite, quartz powder, mica, titanium dioxide, zinc oxide, alumina, magnesium hydroxide, barium sulfate, illite, chlorite, tremolite and other ultrafine powders.

The finished coated powder from the Turbo mill coating production line is widely used in the paper, plastic, rubber, paint and coating, adhesive and sealant and building materials industries.

Technical Parameters

| Model | RTM500 | RTM750 | RTM1000 | RTM1250 |

|---|---|---|---|---|

| Standard drive (kW) | 45 | 75 | 110 | 132 |

| Fineness (μm) | 3 – 75 | 3 – 75 | 3 – 75 | 3 – 75 |

| Capacity (t/h) | 0.5 – 2 | 1 – 5 | 1.5 – 8 | 2 – 10 |

Related Products

Project Cases

Related Posts

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA