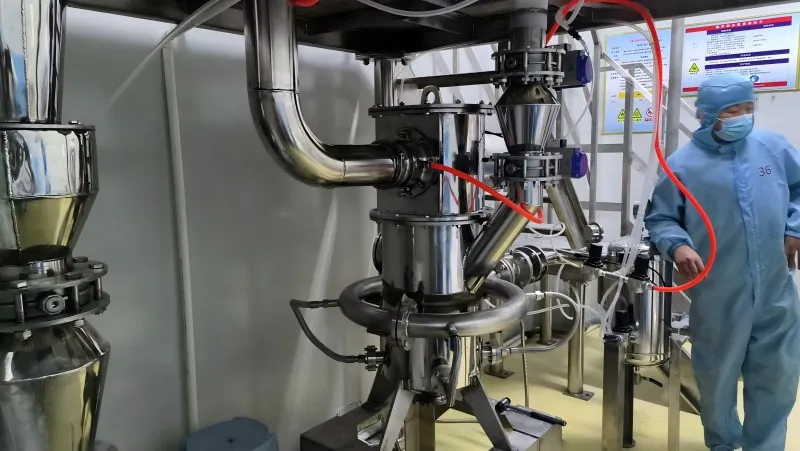

In the pharmaceutical industry, ultrafine pulverization generally has the following characteristics

- Small particle size, concentrated and uniform distribution, saving raw materials;

- Adiabatic expansion of low-temperature and high-pressure air will absorb the heat generated by the collision of materials, will not overheat locally, and retain the biologically active ingredients of the drug, which is conducive to making the required high-quality products;

- Simple quick disassembly and assembly structure, which is conducive to cleaning and replacing material varieties.

Generally, the size of the particles is about 100 microns, and they are ultra-finely pulverized to several microns. After ultra-micro processing, the surface area of the particles increases, and their dispersibility, adsorption capacity, surface activity, etc. have comprehensive changes. It is of great significance for improving the efficacy and saving the dosage.

Project Cases

08/01/2026

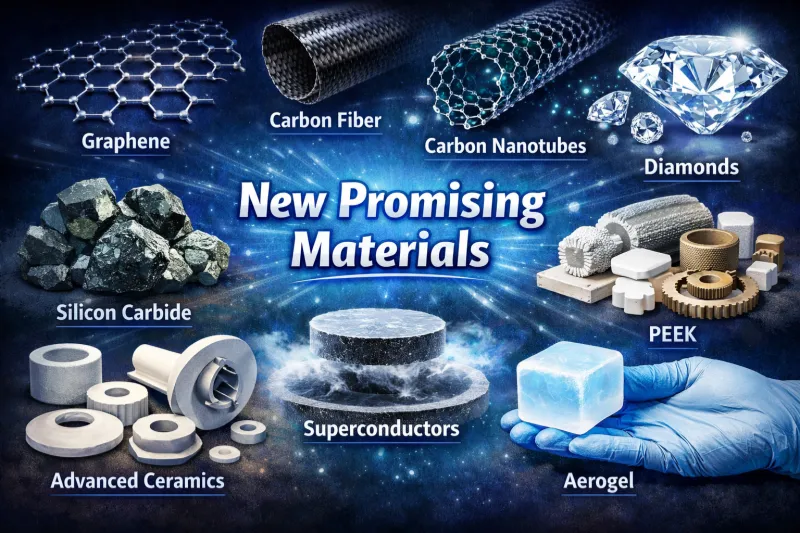

Customer BackgroundThe customer is a leading Australian supplier of advanced ceramics and thermal conductivity materials. Alumina Ultrafine Grinding is critical for this application, as the ...

Read More →

29/12/2025

A well-known Belgian manufacturer of specialty engineering plastics focuses on the R&D and production of high-performance polymers. One of its core products, polyether ether ketone ...

Read More →

18/12/2025

As a global hub for the aerospace and automotive industries, France has an exceptionally strong demand for carbon fiber composite materials. A well-known local composite ...

Read More →

09/12/2025

Project Overview & Challenges: Client / Market: A major marine biotechnology company in Thailand.Product Application: High-quality ultrafine seaweed powder used for health foods, dietary supplements, ...

Read More →

Related Posts

12/01/2026

Are you overwhelmed by the sheer variety of milling technologies on the market? With so many ultrafine pulverization equipment options available, how should one choose ...

Read More →

06/01/2026

With social development and continuous technological progress, many new materials with unique properties have been discovered and rapidly gained popularity.When introducing these materials, especially within ...

Read More →

31/12/2025

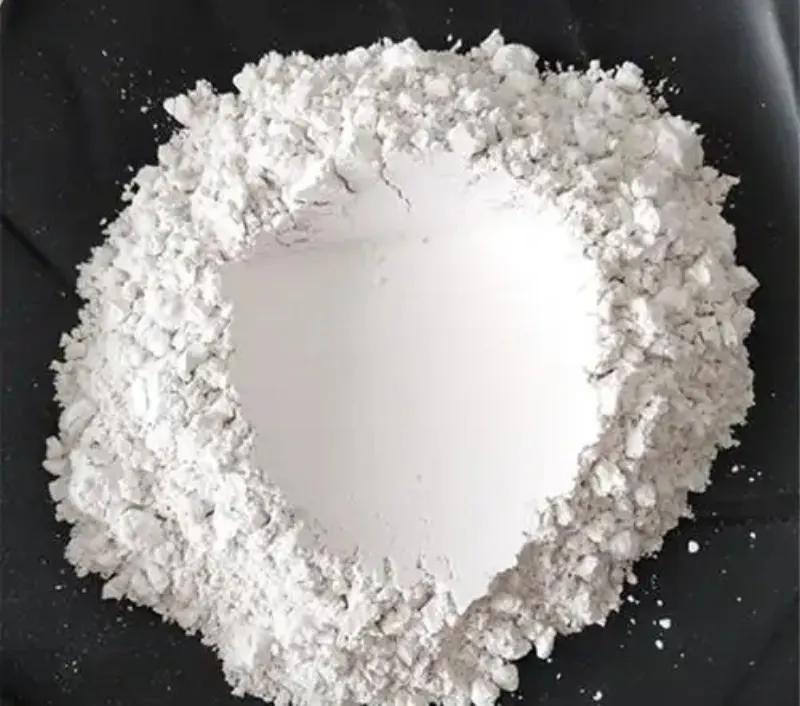

Kaolin, often referred to as the “universal mineral,” is a clay mineral dominated by kaolinite. It is known for its high whiteness, excellent plasticity, high ...

Read More →

25/12/2025

Powder surface modification refers to the targeted treatment of powder surfaces through physical, chemical, or mechanical means. Its purpose is to alter the physicochemical properties ...

Read More →

22/12/2025

Iron-based powders are available in various types, each designed to meet specific industrial requirements. Among these, the iron-based powder ultrafine pulverizer stands out, enabling the ...

Read More →

16/12/2025

With the rapid development of new energy vehicles and energy storage industries, lithium battery materials are continuously evolving toward higher energy density, improved safety, and ...

Read More →

We can provide processes and equipment that meet the following performance indicators

Jet Mill

Suitable for grinding materials with high hardness, high purity and high added value.

Air Classifying Mill

Integration of grinding and classifying

Spiral Jet Mill

On-line cleaning (CIP) and on-line sterilization(SIP)design is optional.

- Full ceramic protection, increased amount of metal <20ppb.

- The physical shape of the particles is stable, the particle size is uniform, and has good dispersibility, and does not cause agglomeration or precipitation.

- Simple quick disassembly and assembly structure, which is conducive to cleaning and replacing materials.

- Low residue, low pollution, less impurities.

- Jet mill can be used instead of impact mill for production, with higher safety and finer particle size.

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA