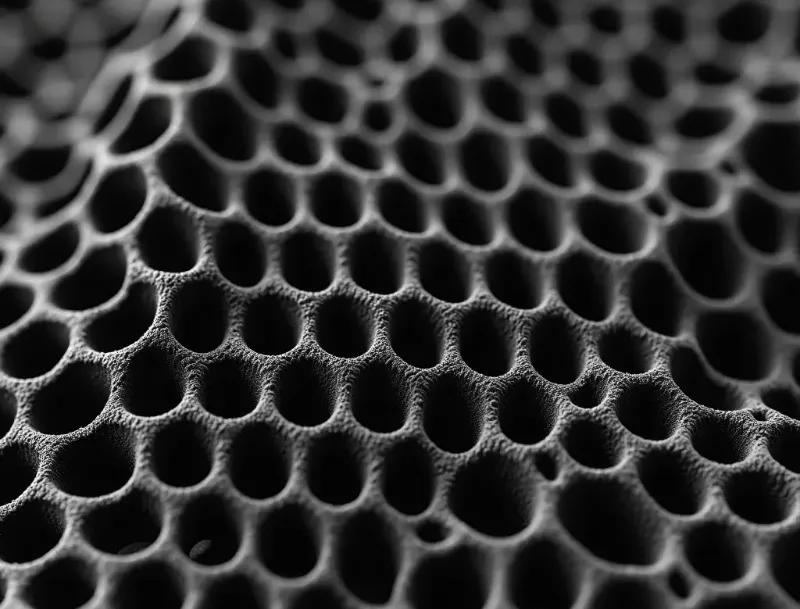

Porous carbon materials have attracted great attention in modern industries for their exceptional surface area, tunable porosity, and chemical stability. From energy storage and catalysis to adsorption and filtration, their performance depends heavily on particle size, surface structure, and uniformity. To fully unleash the potential of porous carbon, ultrafine grinding has become a crucial step—enabling the production of high-quality, uniform carbon powders with controlled porosity and particle size.

Porous Carbon: A Unique Functional Material

Porous carbon can be derived from natural sources such as coconut shells, wood, or coal, or synthesized from chemical precursors. Its main characteristics include:

- High specific surface area: Provides abundant active sites for adsorption, catalysis, and energy storage.

- Controllable pore structure: Micro-, meso-, and macropores can be tailored for different applications.

- Chemical and thermal stability: Resists oxidation and degradation under harsh conditions.

- Electrical conductivity: Makes it suitable for electrodes in batteries and supercapacitors.

These properties make porous carbon indispensable in fields such as activated carbon production, catalyst supports, battery anodes, and high-performance adsorbents.

Why Ultrafine Grinding Is Essential

Raw porous carbon typically appears in irregular particles or agglomerated forms, which can limit its performance. Ultrafine grinding helps overcome these limitations:

- Increases surface area and reactivity: Smaller particles expose more active sites.

- Improves dispersion: Finer powders mix more uniformly in polymers, coatings, and composites.

- Enhances adsorption efficiency: High porosity and fine particle size improve gas or liquid capture efficiency.

- Optimizes electrode performance: In energy storage devices, ultrafine powders improve conductivity and charge/discharge rates.

Challenges in Grinding Porous Carbon

Porous carbon poses several unique challenges during ultrafine grinding:

- Low density and high compressibility: Powders tend to agglomerate or fluff, making uniform grinding difficult.

- Variable brittleness: Some types are fragile, while others are hard and resistant to conventional grinding.

- Pore preservation: Excessive mechanical energy can collapse pores, reducing surface area and functionality.

Therefore, selecting an appropriate grinding method is crucial.

Ball Mill and Jet Mill Solutions for Ultrafine Porous Carbon

Ball mills and jet mills are the most common technologies used for ultrafine grinding of porous carbon:

- Ball mills: Apply impact and shear forces to gradually reduce particle size. They are ideal for large-batch production with controlled particle size distribution.

- Jet mills: Use high-velocity air streams for simultaneous grinding and classification. They minimize contamination, preserve pore structure, and achieve submicron sizes.

Advanced systems often combine grinding with air classification to achieve precise particle size control and uniformity.

Key Process Considerations

- Temperature control: Although porous carbon is stable, excessive heat can cause oxidation or pore collapse. Cooling or inert gas protection is recommended.

- Grinding media selection: Non-contaminating materials such as ceramic or zirconia should be used to maintain purity.

- Moisture management: Powders must remain dry to avoid agglomeration and maintain flowability.

- Batch vs. continuous processing: For large-scale production, continuous jet milling offers higher throughput and consistent quality.

Applications of Ultrafine Porous Carbon

- Energy storage: Used in high-performance supercapacitors, lithium-ion batteries, and fuel cells.

- Catalysis: As catalyst supports for chemical reactions such as hydrogenation and oxidation.

- Adsorption and filtration: In activated carbon filters, gas masks, and water purification systems.

- Composites and coatings: As conductive fillers in polymers, paints, and adhesives.

- Environmental protection: For capturing volatile organic compounds (VOCs), heavy metal ions, and industrial pollutants.

Conclusion: From Raw Carbon to High-Performance Micropowder

Ultrafine grinding is essential to unlock the full potential of porous carbon. By refining particle size and preserving pore structure, its adsorption and electrochemical properties can be greatly improved.

Epic Powder provides advanced ball mills, jet mills, and air classifiers designed for efficient porous carbon processing. These systems ensure uniform, stable, and high-quality ultrafine powders.

With precise control and customized solutions, Epic Powder helps customers build reliable porous carbon ultrafine grinding production lines, turning raw materials into high-value functional powders for energy, catalytic, and environmental applications.