Based on years of experience, we have found that the types and equirements of calcium carbonate in different industries vary greatly. In order to improve the cost-effectiveness and differentiation of products, customers in various industries have put forward more and more diverse and stringent requirements on the physical and chemical properties of calcium carbonate. These changing demands are collectively referred to as calcium carbonate requirements. They cover parameters such as particle size, whiteness, purity, surface treatment, and performance related to specific applications.

Common application areas and index requirements of calcium carbonate

Silicone glue (MS glue):

The applicable performance from high to low is: special active nano calcium, micron-level active light calcium, 3000 mesh active heavy calcium. As well as 1250 mesh active light calcium, 1250 mesh active heavy calcium, other unmodified powders are also used, mostly for lower-end silicone glue products.

Key influencing indicators: fineness, whiteness, activation, particle morphology, water content, water removal rate, specific surface area.

The performance tests for silicone glue include: extrusion, thixotropy, tensile strength, elongation at break, modulus, adhesion, moisture and heat resistance, etc. The above factors must be fully considered and repeatedly verified by experiments before the matching can be successful.

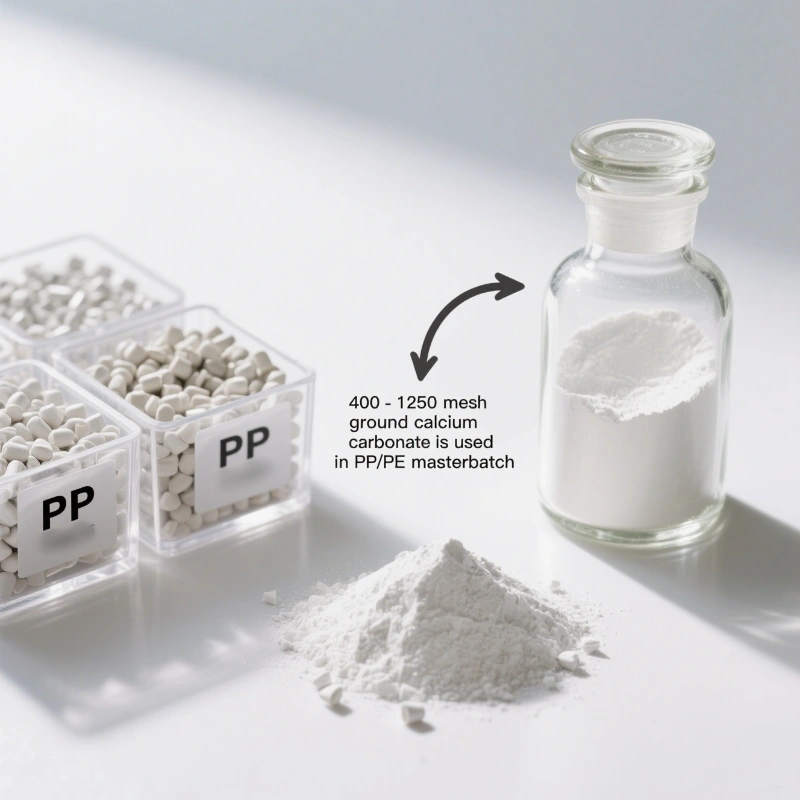

PP, PE filling masterbatch:

For ordinary injection molding and wire drawing, 400-1250 mesh heavy calcium is preferably calcite powder. For bulk bags and non-woven fabric fillers, 1250-3000 mesh raw white calcite powder is used. Others depend on the type and specific requirements of the customer’s products. Key influencing indicators: whiteness, fineness, oil absorption value, 2μm particle accumulation, sedimentation volume.

Blown film material:

Generally, heavy calcium carbonate processed by vertical mill with mesh size of 2500 or above is used, and a certain amount of grinding aid needs to be added.

Key control indicators: whiteness, fineness, -2μm content, oil absorption value, maximum particle size, moisture content, etc.

ABS material:

Applicability from high to low: 2000 mesh and above active heavy calcium, 1250 mesh active light calcium, 1250 mesh active heavy calcium, 600-1000 mesh ordinary heavy calcium.

Key influencing indicators: activation degree, particle morphology, fineness, whiteness, etc.

Calendered film:

Depending on product thickness, toughness, and filler content:

- 800–2000 mesh GCC is commonly used.

- PCC above 1250 mesh is also applied.

- Activated calcium carbonate is widely used.

- High-end products may require nano calcium to improves gloss, color, and aging resistance.

Key Requirements of Calcium Carbonate:

- Whiteness

- Fineness

- -2μm content

- Oil absorption value

- Maximum particle size

- Moisture content

PVC gussets, wood plastic, edge strips, and skirtings:

800-1250 mesh heavy calcium carbonate is the main material, and now most of them use calcite powder. This type of product has very high requirements for the base color and whiteness of calcium carbonate.

Key influencing indicators: ore type, whiteness, base color, fineness, oil absorption value, etc.

PVC leather:

400-1250 mesh heavy calcium is the main material.

Key influencing indicators are: whiteness, fineness, base color, sedimentation volume, oil absorption value, etc.

PU leather:

Mostly use light calcium above 1250 mesh. Key influencing indicators: whiteness, fineness, dispersion, base color, sedimentation volume, oil absorption value, etc.

PVC pipes and fittings:

800-2000 mesh light calcium and heavy calcium. Among them, electrical pipes, pipe fittings, and PPR geothermal pipes have higher requirements, and high-mesh light calcium, active light calcium and even nano calcium can be used.

Key influencing indicators: whiteness, specific surface area, fineness, sedimentation volume, dispersibility, fluidity, etc.

PVC sheets:

Mainly use heavy calcium above 1250 mesh, mostly calcite powder.

Key influencing indicators: whiteness, fineness, oil absorption value, sedimentation volume, etc.

PVC carpets and floor mats:

High-end products use active light calcium, and low-end products use ordinary heavy calcium. Applicability from high to low: 1250 mesh active light calcium, 1250 mesh ordinary light calcium, 1250 mesh active heavy calcium, 800 mesh heavy calcium.

Key influencing indicators: fineness, activation, whiteness, sedimentation volume, etc.

PVC cable materials:

Active heavy calcium and active light calcium above 2000 mesh are used.

Key influencing indicators: activation, fineness, moisture, insulation performance, etc.

Coated paper:

Light calcium above 1250 mesh, heavy calcium above 2000 mesh (mainly vertical mill products), and water-milled heavy calcium are all used.

Key influencing indicators: -2μm content, particle morphology, maximum particle size, sedimentation volume, hydrochloric acid insolubles, etc.

Stationery industry: 1500 mesh light calcium/2500 heavy calcium

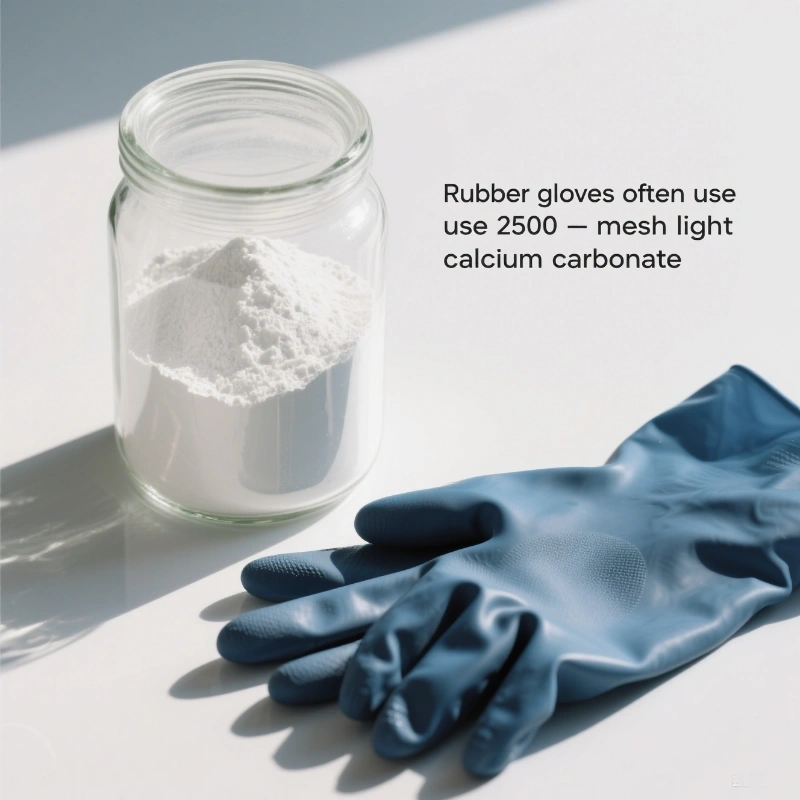

Rubber gloves and other products:

Light calcium above 2500 mesh is more commonly used. Applicability from high to low: active nano calcium, active light calcium above 2500 mesh, ordinary light calcium above 2500 mesh.

Key influencing indicators: activation degree, whiteness, specific surface area, particle morphology, sedimentation volume, etc.

Artificial granite:

In addition to using various specifications of stone rice, it mainly uses 315 mesh special powder, which is processed by special vertical mill equipment and contains certain modifiers.

Key influencing indicators: whiteness, oil absorption value, moisture, etc.

Paint, white primer:

Water-based paint uses light calcium, heavy calcium, and talcum powder above 1000 mesh. Oil-based paint uses more talcum powder and active nano calcium.

Key influencing indicators: adhesion, hiding power, whiteness, fineness, specific surface area, moisture and heat resistance, etc.

EVA shoe material:

Light calcium above 1250 mesh is more suitable, and ordinary heavy calcium is also used. Nano calcium is used for high requirements.

Key influencing indicators: specific surface area, sedimentation volume, whiteness, moisture, etc.

Epoxy resin:

600-1250 mesh heavy calcium is the main one, and 1250 mesh light calcium is also used. Key influencing indicators: whiteness, fineness, sedimentation volume, moisture, etc.

Paper pulp:

400-1500 mesh heavy calcium, most of the coarse powder needs water grinding for secondary processing.

Key influencing indicators: whiteness, hydrochloric acid insoluble matter, sedimentation volume, etc.

Putty powder:

300 mesh heavy calcium generally has low requirements for base color and is easier to match.

Washing powder:

Light calcium above 1250 mesh. Key indicators: calcium content, hydrochloric acid insoluble matter, fineness, whiteness, heavy metals, etc.

Toothpaste, chewing gum:

325-1000 mesh heavy calcium, the key is that the processing environment must comply with the regulations of the Food and Pharmaceutical Administration, and it is best to have CFDA certification. Key influencing indicators: calcium content, whiteness, fineness, food hygiene indicators, etc.

Color powder:

Mainly 800-2000 mesh heavy calcium, key influencing indicators: whiteness, fineness, coarse particles, sedimentation volume, etc.

Waterproof membrane:

Heavy calcium and active heavy calcium above 1250 mesh. Key influencing indicators: whiteness, fineness, moisture, oil absorption value, maximum particle size, etc.

Automotive primer:

Active nano calcium with higher performance is required. Multiple performance tests are required: adhesion, hiding power, moisture and heat resistance, acid and alkali resistance, oil resistance, etc.

Epic Powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. We have many calcium carbonate projects around the world, please click on the assistant for consultation. Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !