Silicon micro powder is made from natural quartz (SiO2) or fused quartz. Fused quartz is obtained by high-temperature melting and cooling of natural quartz. The process involves crushing, ball mill, or vibration mill, Air jet mill, flotation, and acid washing are also used. Purification with high-purity water is part of the process.

Performance of Silica Powder

Silicon micro powder has excellent properties. These include a low thermal expansion coefficient. It also has superior dielectric performance. The thermal conductivity is high. Its suspension performance is good. Additionally, it has the following properties:

- Good insulation properties: Silicon micro powder has high purity and low impurity content. Its stable performance gives excellent electrical insulation and arc resistance. This makes the cured material have good insulation and arc resistance.

- Reduces exothermic peak temperature: It lowers the exothermic peak temperature of epoxy resin curing. It also reduces the linear expansion coefficient and shrinkage rate of the cured material. This eliminates internal stress in the cured material and prevents cracking.

- Corrosion resistance: Silicon micro powder is not easily reactive with other substances. It does not chemically react with most acids or bases. Its uniform particles cover the surface, offering strong corrosion resistance.

- Particle grading: The reasonable particle grading reduces and eliminates sedimentation and layering. It enhances the tensile and compressive strength of the cured material. It improves wear resistance and increases thermal conductivity and flame-retardant performance.

- Silane coupling agent treatment: Silicon micro powder treated with silane coupling agents has good wetting properties for various resins. It has good adsorption ability, mixes easily, and does not form clumps.

- Cost reduction and performance improvement: As a filler, silicon micro powder improves the performance of the cured material. It also reduces product costs.

Raw materials and processing of silicon micro powder

The raw materials include: crystal, translucent and milky vein quartz, metamorphic quartzite, sedimentary quartz sandstone, marine sedimentary quartz sand, river and lake sedimentary quartz sand, powdered quartz, and fused quartz.

Preparation and purification process of silicon micropowder

The process includes flotation of quartz sand, followed by ultra-fine grinding (dry or wet grinding). Then, a combined washing process is used. High-gradient magnetic separation is applied, followed by electrostatic separation. The material is then washed with deionized water and classified.

Ultra-fine grinding (dry or wet grinding): This process grinds quartz sand to ultra-fine silicon micro powder with a particle size of 325-4000 mesh, either under dry or wet conditions.

Classification: Under the action of a hydrocyclone, the 325-4000 mesh ultra-fine silicon micro powder is classified into standard ranges, such as 325-400 mesh, 400-500 mesh, etc.

Combined washing process: Ultra-fine silicon micro powders of different grades are placed in temperature-controlled reaction vessels in different layers. A certain amount of oxalic acid or citric acid, along with small amounts of other auxiliary agents, are added. The reaction occurs at 70°C-100°C for 2-8 hours. After the reaction, harmful trace metals and non-metallic impurities are removed from the ultra-fine silicon micro powder.

High-gradient magnetic separation: This process uses a magnetic separation device with a magnetic strength of 50-15000 Gauss to remove trace iron impurities from the ultra-fine silicon micro powder.

Electrostatic separation: The purpose is to remove trace harmful impurities from the ultra-fine silicon micro powder.

Deionized water washing: After the combined washing process, chemical agents and harmful trace impurities left on the surface of the silicon micro powder are removed in a static cleaning workshop.

Special drying: After deionized water washing, the ultra-fine silicon micro powder is placed in a special dryer in the static workshop. It is then dried to produce high-purity ultra-fine silicon micro powders with particle sizes ranging from 325-4000 mesh, with a moisture content of 0.003-0.01%.

Vacuum packaging: The various grades of ultra-fine silicon micro powders are vacuum-packed to prevent contamination by air.

Surface modification of silica powder

Due to the different interfaces between non-metallic mineral fillers and polymer matrix, compatibility is poor. It is difficult to evenly disperse in the matrix. Direct filling often leads to a decrease in certain mechanical properties of the material. For functional inorganic non-metallic mineral fillers, besides particle size and distribution requirements, good compatibility with the polymer matrix is also essential. After filling, it can reduce costs and enhance the material’s mechanical properties. It improves the overall performance and processability of the material. Therefore, surface modification of non-metallic mineral fillers is necessary.

Surface modification of silicon micro powder mainly uses silane coupling agents. The general formula for silanes is R—SiX3. R represents organic hydrophobic groups, such as vinyl, epoxy, amino, methyl acrylate, and sulfate groups. X represents hydrolyzable alkoxy groups, such as methoxy, ethoxy, and chlorine. Key factors influencing the modification effect include: silane type, amount, application method, treatment time, temperature, and pH value.

Silicon powder processing equipment

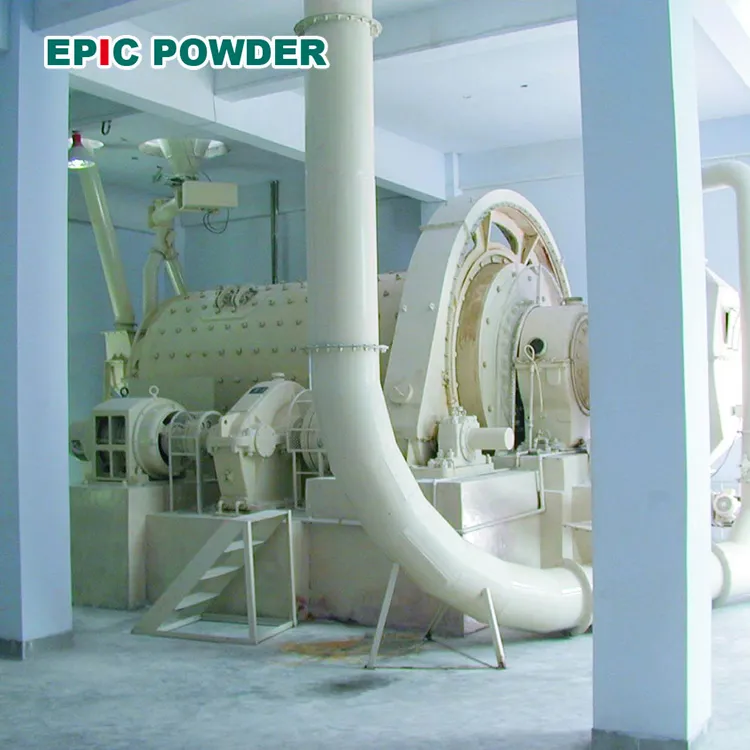

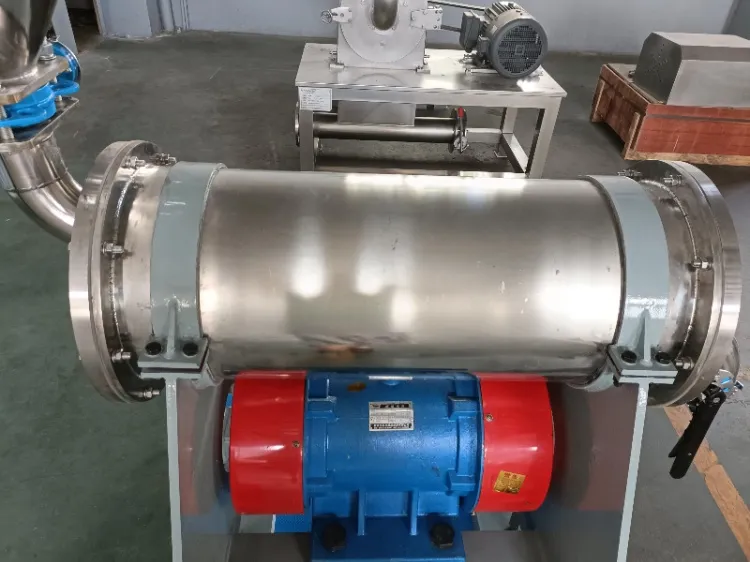

The main production equipment for silicon micro powder includes ball mills, vibration mills, micro powder classifiers, and dryers.

Ball mill: It can be used for both dry and wet grinding of materials. When the ball mill operates, the grinding media and material are lifted to a certain height and then fall. This process repeats continuously. Materials between the grinding media and between the grinding media and the mill wall are impacted. The material is ground into fine powder during the rolling and sliding motion of the grinding media.

Vibration mill: This mill uses the vibration of the grinding media to slide and roll inside the mill chamber. This action grinds the material.

Micro powder classifier: The material is sucked into the classification chamber by the fan. It is classified between the high-speed rotating classifier rotor and the classifier blades. Coarse materials fall along the classifier’s wall and exit through the coarse powder outlet at the bottom. Fine powders pass through the gaps in the rotor blades and exit through the fine powder outlet at the top. This achieves classification.

Dryer: To ensure the extremely low moisture content of silicon micro powder and prevent contamination during drying, a hollow shaft stirring dryer is used. The working principle is as follows: Material enters the dryer through the feed inlet. It is transported to the discharge port by the hollow paddle. During transportation, the material is stirred by the hollow paddle and heated by the hollow paddle and machine jacket. The moisture evaporates and the material is dried.

Conclusion

In conclusion, silicon micro powder offers excellent performance characteristics, such as low thermal expansion, high dielectric strength, and superior thermal conductivity. Its broad applications span across industries like electronics, coatings, and advanced materials. Through deep processing techniques, its properties can be further optimized to meet specific industrial needs, enhancing the overall performance and cost-efficiency of end products. The continued development of silicon micro powder will play a vital role in driving innovation and improving the functionality of modern technologies.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !