Nano alumina is a new type of high-functional fine inorganic material. Since Gleiter and others successfully prepared nano-scale alumina powder in the mid-1980s, the understanding of this advanced material has deepened. Researchers have discovered many of its excellent properties, such as high hardness, high strength, heat resistance, and corrosion resistance. As a result, nano alumina has been widely used in aerospace, national defense, chemical engineering, microelectronics, and other fields. In practical applications, surface modification of nano alumina has always been a crucial process.

Why is modification necessary?

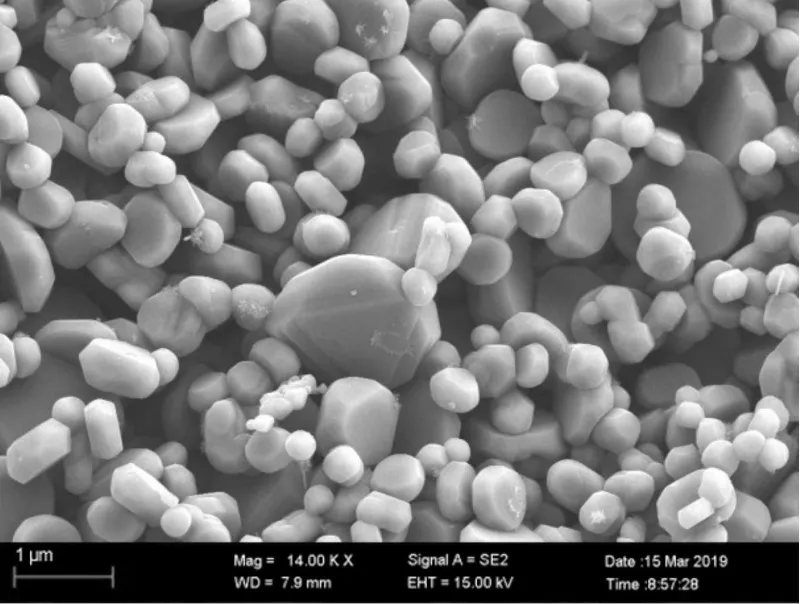

First, as a nanomaterial with unique characteristics, nano alumina has a very small particle size and a large surface energy, which makes it highly prone to agglomeration. Severe agglomeration significantly affects the performance of nano alumina materials.

Secondly, nano alumina can be used as a biological film material for biomedical research. However, due to lattice defects, the crystal surface often exhibits unbalanced charge distribution. The accumulation of surface charge defects and micron-scale space charge regions leads to a grid-like dipole moment. When biological materials contact such a powder surface, localized enrichment may occur, resulting in pore blockage and membrane contamination.

In addition, due to its insulating property and high strength, alumina is used as a filler in coatings, rubber, and other materials to enhance hardness, insulation, ductility, and wear resistance. However, because alumina is a polar substance, it has poor compatibility with nonpolar polymer materials. Therefore, surface modification of alumina has become an important research topic.

Surface Modification Methods

Surface modification refers to the physical or chemical treatment of solid particles to deliberately change their surface physicochemical properties and morphology according to application requirements. Currently, two main modification methods are commonly used: organic surface modification, which primarily uses organic modifiers, and inorganic coating modification, also known as surface coating modification.

Organic Surface Modification

The purpose of organic surface modification of ultrafine particles is to introduce specific organic groups. These groups render the particle surface hydrophobic. This improves the dispersion of particles in organic matrices such as resin, rubber, or paint. It also enhances interfacial compatibility. As a result, the processing performance and mechanical properties of composites are improved. Based on their chemical structure, modifiers are typically classified as higher fatty acids or their salts, low-grade fatty acid esters, and coupling agents.

- Physical Coating Modification

This method uses organic substances—such as polymers, resins, surfactants, water-soluble or oil-soluble polymers, or fatty acid soaps—to coat the particle surface. It is a simple and widely used approach for basic surface modification. - Surface Chemical Modification

In this method, chemical reactions or adsorption occur between the modifier and the particle surface. It is currently the most widely used modification technique in industrial production. - Grafting Modification

Under specific activation conditions, monomeric or polymeric olefins are introduced onto the powder surface. Sometimes, the attached monomer olefins are further polymerized on the surface to achieve modification.

Surface Coating Modification

Surface coating modification refers to the process of uniformly coating the surface of ultrafine alumina particles with smaller solid particles or thin solid films. This alters the surface composition, structure, morphology, and functional properties of the original particles.

According to the reaction environment and the nature of the coating, surface coating methods include chemical precipitation, hydrolysis coating, sol-gel, solvent evaporation, mechanochemical, and gas-phase methods.

Among these, the first three belong to the solution reaction category. In these methods, soluble salt solutions form precipitates through precipitation or hydrolysis. The resulting precipitates then coat the target powder surface.

Epic Powder

Epic Powder we specializes in nano alumina surface modification technology, offering advanced equipment solutions for both organic and inorganic modification processes. Our systems feature precise temperature control, uniform dispersion, and continuous operation for stable, high-quality modified powders. With over 20 years of expertise in ultrafine grinding and modification, Epic Powder provides customized process design and complete production lines that help customers achieve better dispersion, enhanced compatibility, and improved performance of nano alumina across various industrial applications.