Nanoceramics exhibit excellent performance when their nanoparticle distribution is uniform, sintering shrinkage is consistent, and grain growth is even. However, due to the small particle size and strong interparticle forces (such as electrostatic, van der Waals, capillary, and mechanical forces), nanoceramic powders tend to agglomerate, have poor flowability, and significantly affect the powder’s forming properties, leading to reduced material performance. Therefore, studying dispersion methods for nanoceramic powders are crucial.

Physical Dispersion Methods

Mechanical Dispersion

Mechanical dispersion is a physical method that uses external shear or impact forces to fully disperse nanoparticles in a medium. This is generally achieved through devices like ball mills, stirred mills, planetary mills, and shear-type high-speed stirrers.

- Ball Milling: While effective, it may introduce impurities from the wear of the balls and mill components, which can affect the purity and properties of the slurry.

- Stirred Mills and Planetary Mills: These methods offer higher grinding efficiency and are commonly used to disperse ultrafine powders. However, ball milling can alter the physical and chemical properties of the powder, so careful control of the milling time is essential.

- Shear-Type High-Speed Stirrer: This method provides excellent dispersion but can lead to the entrapment of air, causing foaming in the slurry.

Ultrasonic Dispersion

Ultrasonic dispersion uses high-frequency sound waves to create high temperatures, pressures, and strong shock waves that reduce interparticle forces, effectively preventing particle agglomeration.

- However, once the ultrasonic vibration stops, particles may re-agglomerate. Additionally, after a certain period, further treatment cannot reduce the particle size, and the ultrasonic treatment is less effective for very fine particles.

Chemical Dispersion Methods

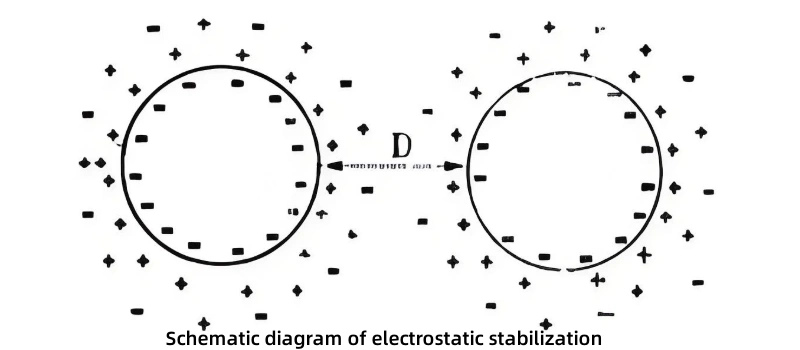

Nanoceramic powder chemical dispersion mechanisms include the double-layer (electrostatic) stabilization mechanism, steric hindrance stabilization mechanism, and electrostatic-steric hindrance stabilization mechanism.

- Double-Layer (Electrostatic) Stabilization Mechanism

Electrostatic stabilization increases the particle surface charge by adjusting the pH value or adding electrolytes, forming a double-layer structure. This increases the Zeta potential, creating electrostatic repulsion and stabilizing the system. The stability of the system is achieved through the balance between van der Waals attraction and electrostatic repulsion forces.

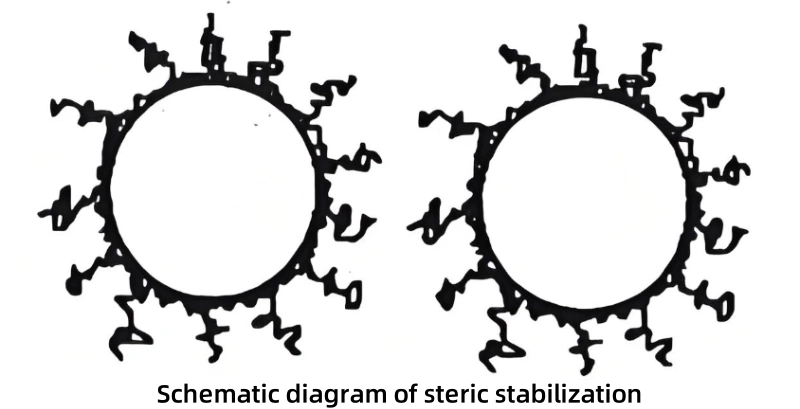

- Steric Hindrance Stabilization Mechanism

This involves adding polymers that anchor to the particle surface. The solvent chains of these polymers extend in the medium, creating a steric layer that prevents particle aggregation and gravity-induced settling. For effective steric stabilization, the polymer must strongly adsorb to the particle surface and extend sufficiently in the medium.

- Electrostatic-Steric Hindrance Stabilization Mechanism

A combination of electrostatic and steric effects stabilizes the particles. A charged polymer layer on the particle surface creates both electrostatic repulsion and steric hindrance to prevent particle aggregation.

Epic powder

Epic Powder, with its advanced grinding and breaking equipment like ball mills, air jet mills , air classifier mills and pin mills, optimizes nanoceramic powders dispersion. It carefully controls particle size, distribution, and dispersion properties. Epic Powder’s customized equipment solutions ensure high-performance ceramics for diverse applications. These solutions improve nanoceramic particle uniformity, enhancing material properties and performance. By integrating mechanical and chemical dispersion techniques, Epic Powder drives innovation in powder processing. The company meets the demanding requirements of industries such as electronics, automotive, and energy storage.