An ultrafine grinding mill is specialized equipment designed to reduce materials into extremely fine particle sizes, typically below 10 microns.

Unlike traditional mechanical impact mills, ultra fine grinders achieve micron or even submicron fineness through high-speed airflow, centrifugal force, and precise classification.

These mills are widely used in industries such as minerals, ceramics, chemicals, pharmaceuticals, pigments, and battery materials, where product purity and particle size control are critical.

Working Principle of UltraFine Grinding Mill

Although the working principle varies among different types of mills, the fundamental concept remains the same — reducing particle size through energy input and performing precise classification.

Feeding and Pre-Classification

Raw materials are first fed into the grinding chamber.

The system may include a pre-classifier to separate coarse particles, preventing overload and improving efficiency.

Grinding Zone

In the grinding zone, the material is subjected to intense mechanical, pneumatic, or centrifugal forces.

Common types include:

- Jet Mill: Uses high-speed compressed air to make particles collide with each other, achieving contamination-free ultrafine grinding.

- Air Classifier Mill: Utilizes the high-speed impact of the grinding disc combined with centrifugal force; particles collide with the grinding ring and are pulverized.

- Ball Mill + Classifier System: Combines traditional mechanical grinding with air classification to control particle size distribution.

The goal is to achieve the desired fineness while avoiding overheating or contamination.

Classification and Collection

After grinding, the material passes through an integrated air classifier.

Fine powder is collected, while coarse particles are returned to the grinding zone for further milling.

This closed-loop process ensures a stable particle size distribution and consistent product quality.

Key Features of Ultra Fine Grinding Mills

Precisely controlled particle size and narrow distribution

Contamination-free operation, ideal for high-purity materials

Low heat generation, suitable for heat-sensitive materials

High energy efficiency and reduced power consumption

Automated operation and stable performance

Industrial Applications

Thanks to their ability to produce high-purity, uniform, and ultrafine powders, these mills are indispensable across many high-tech and traditional industries.

Nonmetallic Minerals and Building Materials

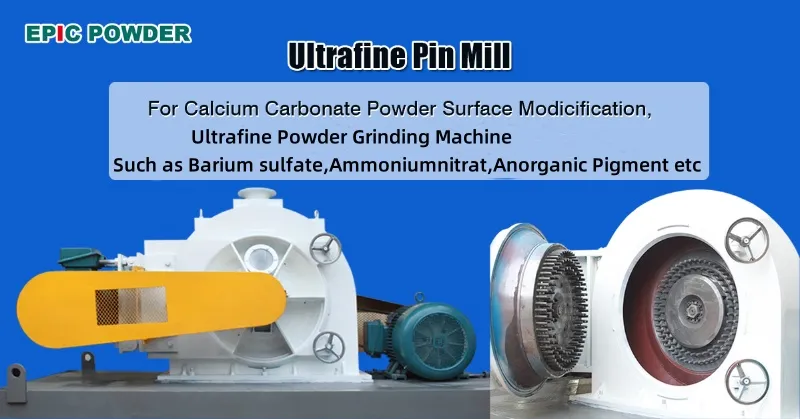

Applications: Calcium carbonate, talc, quartz, kaolin, cement clinker, gypsum

Uses:

- Improve filler performance in plastics, coatings, and paints

- Enhance cement and concrete strength and surface smoothness

Typical Fineness: D97 = 2–10 µm

Chemicals and Pigments

Applications: Titanium dioxide, iron oxide, ceramic pigments, fillers

Uses:

- Increase color strength and hiding power

- Improve dispersion in coatings and inks

Advantages: Narrow particle size distribution ensures stable product quality

Pharmaceuticals and Food

Applications: Active pharmaceutical ingredients (API), excipients, herbal extracts, milk powder, flavors

Uses:

- Enhance bioavailability through micronization

- Improve solubility and mouthfeel in food applications

Compliance: Made of stainless steel, easy to clean, and compliant with GMP standards

New Energy Materials

Applications:

- Lithium battery anode materials (natural/artificial graphite)

- Cathode precursors (LFP, NCM)

- Silicon powder for photovoltaics

Uses: - Increase surface area and enhance electrochemical performance

- Achieve D50 < 5 µm with extremely low impurity content

Key Benefit: High purity and low energy consumption

Environmental Protection and Resource Recycling

Applications: Fly ash, slag, tailings, industrial solid waste

Uses:

- Activate materials for eco-friendly cement

- Recover valuable fine powders from waste streams

Advantages: Supports resource recycling and circular economy

Advantages of UltraFine Grinding

| Feature | Advantage |

|---|---|

| No Grinding Media | Prevents contamination (compared with ball mills) |

| Low Heat Generation | Suitable for heat-sensitive materials |

| Energy Efficiency | Up to 30% lower energy consumption than traditional mills |

| Compact Design | Small footprint, easy to integrate into production lines |

| Automated Control | Real-time monitoring of particle size and output |

Why Choose EPIC POWDER?

EPIC POWDER specializes in ultra fine grinding, classification, and surface modification systems and has over 20 years of industry experience.

The company provides integrated solutions for calcium carbonate, silicon powder, lithium battery materials, ceramics, and chemical powders.

Our advantages include:

- Customized system design

- Flexible equipment combinations (jet mill, ball mill, classifier, etc.)

- Optional high-purity ceramic components

- Global technical support and remote assistance

Choosing EPIC POWDER means gaining a high-precision, stable, and cost-effective powder processing solution.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact Zelda online customer representative for any further inquiries..”

— Posted by Emily Chen