Ultrafine powder grinding technology is regarded as a cutting-edge, high-tech field. It transforms materials’ optical, electrical, magnetic, mechanical, thermal, and surface properties. These changes often yield exceptional effects in applications. Ultrafine powders are categorized into micron, submicron, and nanoscale powders. Internationally, powders with particle sizes larger than 1μm are micron-grade. Those between 0.1–1μm (100nm–1000nm) are submicron-grade. Powders between 0.001–0.1μm (1nm–100nm) are nanoscale, also called nanomaterials. Broadly, nanomaterials have at least one dimension in the nanoscale.

Ultrafine powder grinding technology involves preparation, classification, separation, drying, transportation, mixing, homogenization, surface modification, particle compounding, testing, packaging, storage, and application techniques. It also includes safety measures during preparation and storage.

Properties of Ultrafine Powders

Huge Specific Surface Area: As particle size decreases, the number of atoms on the surface increases significantly, leading to a rapid increase in surface energy.

Lower Melting Points and Chemical Instability.

Tendency to Agglomerate: Smaller particles with high surface energy tend to gather together to reduce surface energy. To prevent agglomeration, high polymers or electrolyte ions are often used as protectants.

Strong Light Absorption: Bulk metals have low visible light absorption but high reflectivity. Nano-sized metallic powders absorb visible light strongly and reflect less, often appearing black.

Superparamagnetism or High Coercivity: When particles reach a critical size, they exhibit superparamagnetism or high coercivity. For example, α-iron, Fe3O4, and Ni particles of sizes 5–20nm become superparamagnetic.

Good Thermal Conductivity: Ultra-fine powders have excellent thermal conductivity, especially at low temperatures, with almost no thermal resistance.

Changes in Conductivity: Metal micro-powders lose conductivity drastically, while non-metal powders like silver (10–15 nm) become non-conductive, and SiO2 (15–20 nm) becomes conductive.

Improved Mechanical Properties: Copper particles with a diameter of 6 nm have a hardness 500% higher than that of bulk copper.

Ultrafine powders show unique properties, promising applications in catalysis, electronics, information, optics, medicine, and magnetic media, expanding research fields.

For non-metallic minerals like calcium carbonate, kaolin, talc, bentonite, mica, wollastonite, graphite, and attapulgite, mechanical ultrafine crushing is a key processing method. Choosing the right process and equipment enhances efficiency, product quality, and cost savings.

How to Choose an Ultrafine powder Grinding Process?

Mechanical ultrafine grinding produces powders with d97≤10μm. It includes dry and wet methods. Dry grinding is widely used for hard, brittle materials. It has a short process, simple operation, easy control, lower investment, and reduced operating costs. No additional dehydration equipment is needed for dry powders. Wet ultra-fine grinding, due to the grinding effect of water and its higher density compared to air, offers better dispersion of powders and high-efficiency grinding, but requires post-drying and filtration equipment. This often results in particle agglomeration, which may require deagglomeration afterward.

For materials like calcite, talc, and wollastonite, dry grinding is generally preferred when the product fineness is d97 ≥ 5μm.

For producing powders with d97 < 5μm, or when the product can be sold as slurry or filter cakes, wet grinding should be prioritized.

If the material has undergone prior wet processes (such as washing or purifying), wet ultra-fine grinding should be selected regardless of the final product’s particle size requirements.

If post-grinding processing requires wet techniques, wet ultra-fine grinding should also be chosen.

In special cases, such as the processing of mica for pearlescent pigments, wet ultra-fine grinding should be used to preserve the sheet-like particle shape and surface smoothness.

How to Choose Ultra-fine Grinding Equipment?

Equipment selection depends on material properties (hardness, density, moisture, feed size), throughput, product fineness, particle size distribution, purity, particle shape, and process configuration. Equipment must meet product fineness, design throughput, and maximum feed particle size requirements.

Air Jet Mills: One of the primary ultrafine powder grinding devices. They are especially suitable for powders with fine particle sizes, high purity, and high added value. They can process powders with d97 = 3–5μm, with production rates ranging from dozens of kilograms to several tons per hour. They are widely used for materials like talc, graphite, wollastonite, zircon, kaolin, baryte, non-metallic minerals, abrasives, chemicals, pigments, pharmaceuticals, health products, and rare earth metals.

Air Classifier Mills: Widely used in non-metallic minerals like coal-based kaolin, calcite, marble, chalk, talc, and pyrophyllite. It’s also used for chemicals and pesticides. It achieves d97=10μm (1250 mesh). With high-performance classifiers, it produces d97=5–7μm powders.

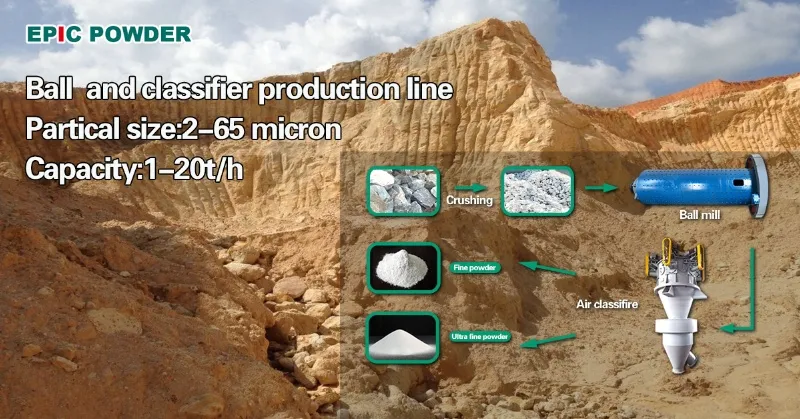

Ball Mills: These mills have a large diameter-to-length ratio and use balls or steel segments as grinding media. The particle size distribution of the product is typically wider. Ball mills are often used in combination with classifiers for closed-circuit grinding. This method is commonly used for producing ultra-fine heavy calcium carbonate with a feed size of ≤5mm, producing products with a d97 of 5–45μm.

Turbo Mills: Suitable for grinding limestone, calcite, marble, talc, wollastonite, kaolinite, barite, quartz, feldspar, etc. The feed size is ≤30mm, and the product fineness can be adjusted between d97 = 40–10μm (400–1250 mesh).

epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !