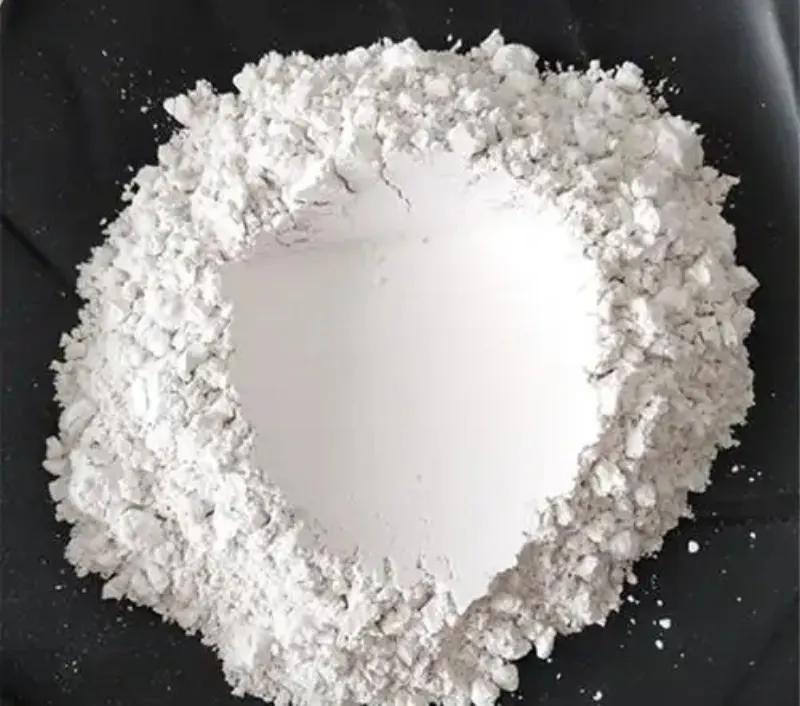

Kaolin, often referred to as the “universal mineral,” is a clay mineral dominated by kaolinite. It is known for its high whiteness, excellent plasticity, high refractoriness, and outstanding chemical stability. Kaolin is widely used in paper, ceramics, coatings, rubber, plastics, pharmaceuticals, and even defense industries.

However, the true value of kaolin largely depends on its powder fineness, particle size distribution, particle morphology, and purity. The realization of these superior properties relies heavily on advanced grinding equipment. Modern ultrafine grinding technologies not only reduce kaolin to the micron or even submicron scale, but also optimize its physicochemical properties, significantly increasing product added value.

The Decisive Influence of Grinding Fineness on Kaolin Performance

The finer the kaolin particles, the larger the specific surface area and the higher the surface activity. This directly enhances several key properties:

- Whiteness and hiding power: Ultrafine powders with more than 80% below 2 μm can reach a whiteness above 95%. They are widely used in high-grade paper coating and paints, improving paper gloss and ink absorption.

- Plasticity and bonding strength: Fine particles enhance interparticle bonding, improving formability and dry strength of ceramic bodies.

- Dispersibility and suspension stability: Kaolin easily forms stable suspensions in water, making it suitable for coatings and rubber fillers.

- Refractoriness and chemical stability: After fine grinding, sintering temperature becomes easier to control, with refractoriness reaching 1770–1790°C.

- Adsorption capacity and cation exchange capacity: Increased specific surface area improves performance in catalytic and environmental applications.

Traditional coarse grinding cannot meet these requirements. In contrast, advanced grinding equipment enables precise control of particle size distribution, transforming kaolin from a conventional filler into a high-end functional material.

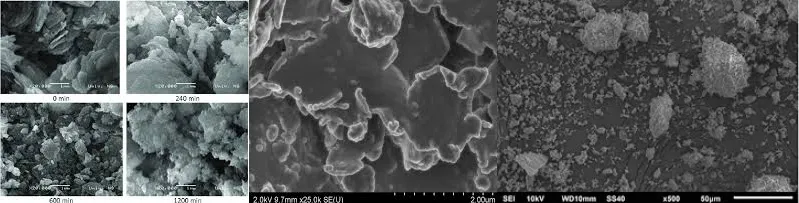

(The SEM image above shows ultrafine ground kaolin powders with regular plate-like particles, smooth surfaces, and uniform distribution—an essential foundation for high-end applications.)

Types of Advanced Grinding Equipment and Their Optimization Effects on Kaolin

Currently, mainstream kaolin grinding equipment includes ultrafine vertical mills, ring roller mills, jet mills, stirred mills, and high-speed mechanical impact mills. Each type has its own advantages and can be applied to dry or wet ultrafine processing of different kaolin types (hard, soft, and sandy kaolin).

| Equipment Type | Typical Product Fineness (μm) | Capacity (t/h) | Main Advantages | Performance Enhancement for Kaolin |

|---|---|---|---|---|

| Ultrafine vertical mill (e.g. GKLMX, CLUM series) | 3–45 | 3–45 | Integrated grinding, classification, and conveying; energy-efficient | Narrow size distribution, high whiteness, large-scale production |

| Ring roller mill (e.g. HCH, HGM series) | 5–74 | 1–22 | Multi-layer rolling, high degree of spheroidization | Improved dispersibility and plasticity; ideal for coatings |

| Jet mill (steam or air fluidized bed) | 1–30 | 0.5–10 | No grinding media contamination; regular particle shape | High purity and high activity; suitable for paper coating |

| Stirred mill (vertical wet grinding) | 1–10 | 1–15 | Media grinding with excellent delamination effect | Preserves plate-like structure; enhances hiding power and adsorption |

| High-speed mechanical impact mill | 3–74 | 2–20 | Impact crushing with high efficiency | Rapid size reduction combined with impurity removal |

These systems are often equipped with high-precision classifiers (such as turbo classifiers) to ensure a narrow particle size distribution. Negative-pressure operation and pulse dust collection enable clean and environmentally friendly production, fully meeting modern environmental standards.

Practical Applications and Future Outlook

In the paper industry, kaolin processed by jet mills with particle sizes below 2 μm can increase coated paper gloss by more than 30%. In ceramics, delaminated kaolin produced by stirred mills improves green body strength and sintering uniformity. In coatings and plastics, products from ultrafine vertical mills enhance hiding power and scrub resistance.

As market demand grows for “double 90” products (whiteness ≥ 90% and −2 μm content ≥ 90%), advanced grinding equipment is driving kaolin’s transformation from a low-value raw material into a high-value functional material.

In the future, combined with AI-based intelligent control and surface modification technologies , kaolin performance will continue to advance, expanding into emerging fields such as new energy batteries and environmental adsorption.

Conclusion

Advanced grinding equipment is not merely a processing tool for kaolin—it is the key enabler of its outstanding performance . Selecting the right grinding solution can significantly improve product quality, reduce energy consumption, and enhance market competitiveness, ultimately achieving efficient resource utilization and sustainable development.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact Zelda online customer representative for any further inquiries.”

— Posted by Emily Chen