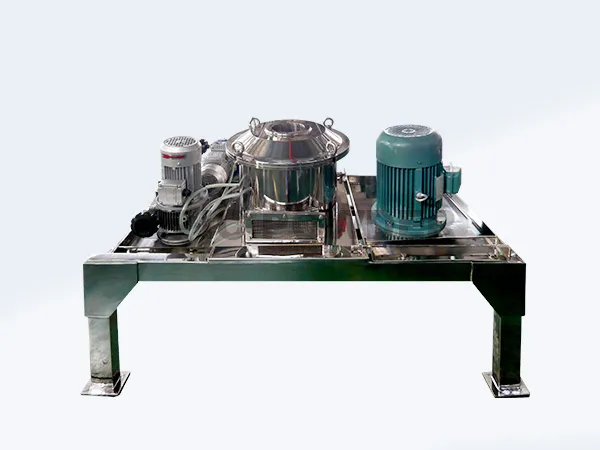

Table Roller Mill - Vertical Mill

The ultra-fine vertical mill is currently the super-large ultra-fine grinding equipment in Asia, which has been successfully applied in the market and has mature technology. It can replace imported equipment and is an ideal equipment for large-scale production of ultrafine powder with high efficiency, high yield, environmental protection and energy saving.

It is suitable for superfine grinding of non-metallic minerals such as calcium carbonate superfine powder, limestone, barite, calcite, kaolin, gypsum, pyrophyllite and graphite. It can provide high-quality fillers and additives for industries such as papermaking, plastics, coatings, rubber inks, and chemicals.

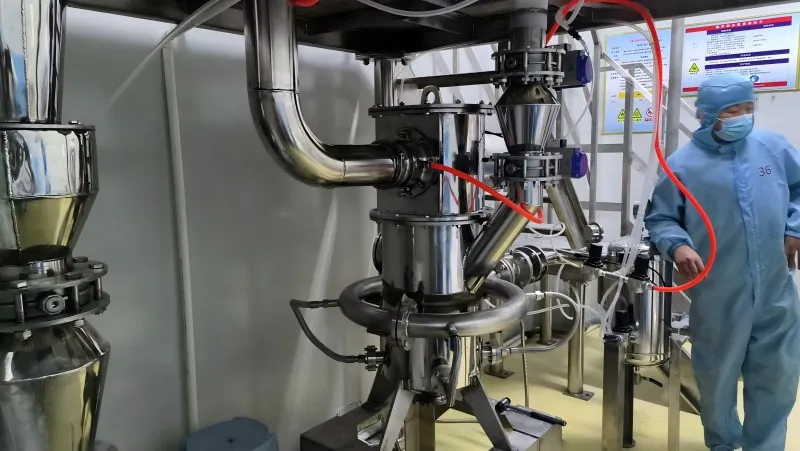

Working Principle

The motor drives the reducer. In the mill, material falls from the feed opening onto a grinding disc. It moves to the edge of the mill due to centrifugal force and the grinding roller. Shredded material overflows from the edge. At the same time, wind from the nozzle ring speeds to the efficient separator. It is with the vertical mill. After the separator, meal returns to the mill wheel and grinds again. The fine powder is ground with the air flow. It collects in the system’s dust collector, which is the product. Larger granular materials don’t get picked up by the hot gas flow and metal parts accidentally get in. They sink from the wind ring and are scraped out by the scraper. Then, they circulate back into the grinding for grinding again.

Features And Benefits

1.High grinding efficiency.

The roller sleeve and liner grinding curve specially designed for ultra-fine powder grinding makes it easier to form a material layer, with high grinding efficiency and high yield of one-time grinding.

2.High productivity and energy saving

The production capacity of a single machine is large, and the output is as high as 50t/h, which is equivalent to more than 5 micro-powder mills. It can save energy by 30-50% compared with ordinary mills to produce products with the same fineness.

3.Low operation and maintenance cost

The grinding roller can be turned out of the machine by hydraulic device, which is convenient for maintenance. Grinding roller sleeves can be turned over for use, prolonging the service life of wear-resistant materials, with low wear and tear. Grinding rollers and grinding disc liners are made of special materials, with long service life.

4.Low noise and environmental protection

The whole system has small vibration and low noise. It adopts an overall sealed negative pressure operation system and an air box pulse dust removal system. There is no dust spillage, and a dust-free workshop can basically be realized.

5.High degree of automation

It adopts PLC automatic control system and can realize remote control, which is easy to operate, easy to maintain and reduce labor costs.

6.Product quality is stable

The material stays in the mill for a short time, reducing repeated grinding, and the finished product has less iron content, high whiteness and purity, uniform particle shape, narrow particle size distribution, small cut point, good fluidity and strong adaptability.

7.Product quality is stable

The material stays in the mill for a short time, reducing repeated grinding, and the finished product has less iron content, high whiteness and purity, uniform particle shape, narrow particle size distribution, small cut point, good fluidity and strong adaptability.

8.Low comprehensive investment cost

Integrating crushing, drying, grinding, grading, and conveying, the process flow is simple, the structure layout is compact, and the floor space is small, only 50% of the ball mill. It can be arranged in the open air, the construction cost is low, and the investment cost is directly reduced.

Application fields of Table Roller Mill

Table roller mills are robust and time-proven mills for soft to medium-hard mineral raw materials and industrial bulk materials. The advantages of the table roller mill are the simple fineness adjustment and fast product change. Table roller mills are used wherever a high degree of production flexibility is demanded, for example for:

- Limestone

- Gypsum

- Dolomite

- Talc

- Petroleum coke

- Bentonite

- Quick lime

Related Products

Project Cases

Related Posts

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA