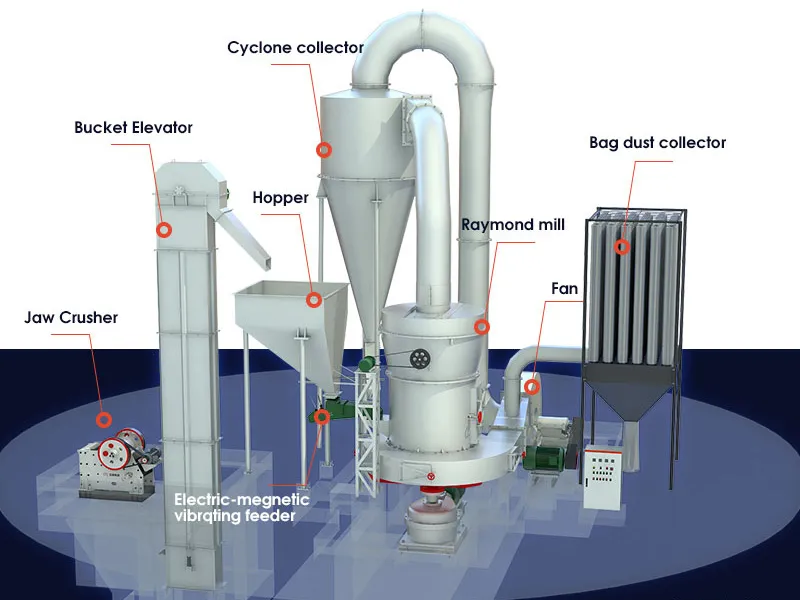

Raymond Mill

The Raymond mill, also called Raymond roller mill, combines grinding, classifying, and if necessary, drying, in one machine to produce precisely sized powders to meet exact production specifications. It is an efficient fine grinding machine for large-scale powder production.

Applied materials:

various non-flammable and explosive minerals such as gypsum, talc, calcite, limestone, marble, potash feldspar, barite, dolomite, granite, kaolin, bentonite, medical stone, iron ore, etc.

Working Principle

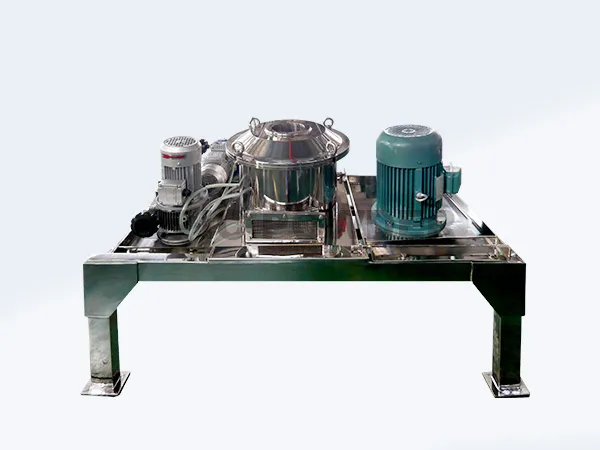

Pin mill work by similar principle as hammer mills (impacts and shearing) but with typically faster tip speed rotor-stator configuration of intermeshing pins which impact the particles as solids are directed through the intermesh pins. The mill product leaves by centrifugal forces to the periphery and is then collected or further processed. This method of milling is most likely to produce materials in the micronized regime (as less than 40 micrometres) and with uniform product size. Cooling of the rotating disks is a useful way of removing heat from the mill.

The materials are uniformly fed into the grinding chamber by the feeding system, and are strongly impacted by the high-speed rotating grinding movable disk. At the same time, they are subjected to various comprehensive forces such as friction, shearing, and collision between the static disk and the gear ring, so that the materials are crushed. According to the different properties of the materials, the grinding movable disk and the static disk can be combined with different structures to meet the crushing needs of different materials.

Features And Benefits

- It achieves smaller particle size than hammer mill at relatively reasonable energy consumption.

- Recent advances have improved heat removal from the mill using cryogenic conditions.

- Pin mill occupies little floor space.

- It has a wide range of applications; can be used in milling dry, moist or slurry materials.

- The two needle discs in the mill rotate at high speed in opposite directions;

- The fineness of the product is achieved by adjusting the speed of the dial;

- The machine is easy to clean, just open the grinding door;

- No sieve, smooth discharge, high capacity and low operation cost; dual power can be used to achieve a linear speed above 200m/s to obtain greater crushing power.

Related Products

Project Cases

Related Posts

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA