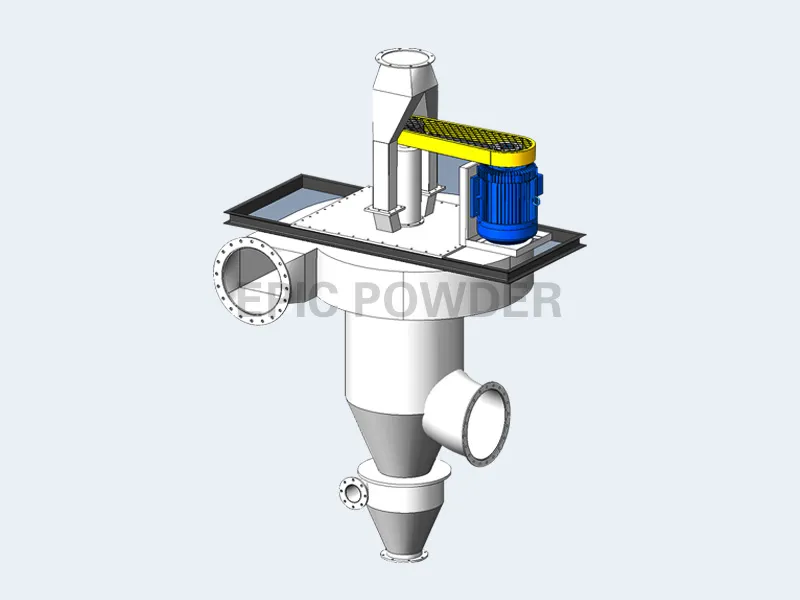

Ball Mill And Air Classifier Production System

Cooperate with the classifier to produce products of multiple particle sizes at the same time. According to different materials and application industries, the production capacity and particle size range will be different.

Working Principle

After coarse crushing, the material is fed into the ball mill through a controllable feeding device. The grinding medium in the mill repeatedly impacts and grinds the material by virtue of the kinetic energy obtained when the mill rotates. The crushed material is discharged into the suction tank through the tail of the ball mill, and then transported to the classifier for classification by negative pressure. The qualified fine powder is collected by cyclone collector or dust collector, The coarse particles after classification are discharged from the lower end of the classifier, and then re-enter the ball mill for crushing through the feeding pipe.

Ball Mill And Air Classifier Production System

Ball mill

The design is different from traditional cement mills and mining and metallurgical mills, and meets the requirements of German superfine filler grade mineral processing.Optimize the aspect ratio to prevent excessive grinding and achieve optimum grinding results.Optimize the opening ratio and opening design of the jaws, and increase the grinding fineness with a smaller grinding media.The slab-type grinding tail discharges, the discharging is smooth, there is no grinding phenomenon, and the cylinder does not need to be cooled.Grinding media according to product requirements, reasonable ratio, high filling rate, high efficiency.Grinding aids when grinding ultrafine powders to improve grinding efficiency.Optimize the matching of drive and grinding energy to maximize energy savings.And the classifier forms a closed system, negative pressure conveying, no dust.Optimize the shape and material of the lining and grinding media, according to German standards, reduce the damage rate and improve the grinding efficiency.Hard minerals can be designed with no iron pollution, and the lining and grinding bodies are made of alumina ceramic, quartz, SILEX or special materials.

Classifier

Different models of Classifier could be selected depending on different fineness of products. HTS series Classifier are suitable for classifying of D97:3~20μm products, ITC series for classifying of D97: 8~45μm products. Wide range of adjustment is available with each Classifier and the application is extensive in market.By using different combinations of single or multiple classifiers, products with different fineness can be produced at the same time, or the product specifications can be changed at any time according to the demand, which has greater flexibility.The classifier is equipped with speed sensor and control system to measure, evaluate and compensate the air temperature, air pressure, air volume and filter pressure difference, so as to ensure the stability of product quality.

Technical Parameters

| MODEL | 1530 | 1557 | 1850 | 1870 | 2250 | 2270 | 2450 | 2470 | 2660 | 2670 | 3070 | 3090 | 3280 | 3290 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder diameter (m) | 1.5 | 1.5 | 1.83 | 1.83 | 2.2 | 2.2 | 2.4 | 2.4 | 2.6 | 2.6 | 3 | 3 | 3.2 | 3.2 |

| Cylinder length (m) | 3 | 5.7 | 5 | 7 | 5 | 7 | 5 | 7 | 6 | 7 | 7 | 9 | 8 | 9 |

| Motor power (kw) | 75 | 132 | 160 | 250 | 250 | 380 | 320 | 475 | 500 | 630 | 800 | 1000 | 1250 | 1400 |

| Feeding size (mm) | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 |

| Fineness (um) | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 |

Related Products

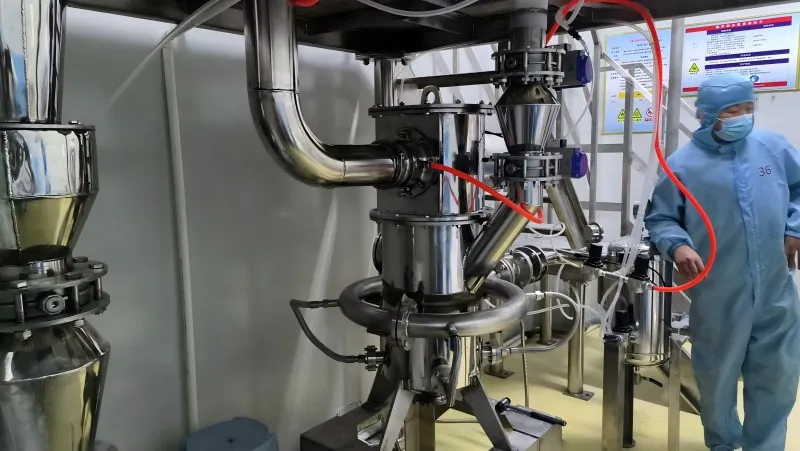

Project Cases

Related Posts

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA