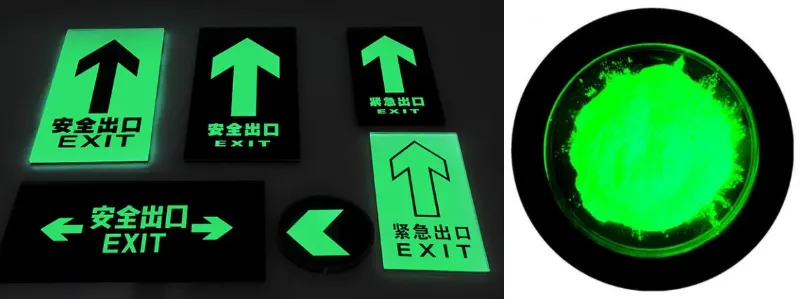

When taking the subway, people sometimes get lost. In subway stations, glowing exit signs are everywhere. What are these glowing materials made of? Research shows they use rare earth long afterglow phosphors. These are widely used in subways, malls, and office buildings. They guide exits, fire safety, evacuation, and escape routes. Rare earths long afterglow phosphor is a rare earths luminescent material. So, what is a rare earth luminescent material? First, let’s understand “rare earth.” The periodic table includes 15 lanthanides, from La to Lu. Plus Yttrium (Y) and Scandium (Sc), totaling 17 rare earth elements. In luminescent materials, rare earth elements are added. Due to their atomic radius and unique optical electronegativity, they act as host components or as activators, sensitizers, or dopants. This gives them a unique role in luminescent materials. Thus, they are called rare earth luminescent or fluorescent materials.

Application of rare earth luminescent materials

In agricultural light-conversion films, luminescent materials act as sunlight converters. They are added to plastic films to make agricultural films or greenhouses. This improves light quality for photosynthesis. It increases light energy efficiency and promotes early maturity and yield. Currently used converters include two main types: Organic europium (or samarium) complexes or chelates, And rare earth-activated red-light inorganic phosphors.

Secondly, in military applications, rare earths luminescent materials are widely used.

They can be used to make various types of displays. These displays are well-suited for fighter jets and attack aircraft. They are also ideal for use in armed helicopters. This significantly enhances the functions and performance of end products.

Rare earths phosphors can also be used in X-ray intensifying screens. Many rare earth phosphors are suitable for this purpose. They play a key role in diagnosing diseases and protecting health.

Current status of development of rare earth luminescent materials

Rare earths luminescent materials mainly include:

Tricolor phosphors, LED phosphors, and long afterglow phosphors. Their applications have expanded far beyond indoor lighting. Now they’re used in street lighting, square lighting, and landscape lighting. They’re also applied in various types of special-purpose lighting. In addition, they’re used in high-end displays for phones, computers, and TVs.

Preparation method of rare earth luminescent material

Grinding equipment

Grinding equipment is essential for improving rare earth luminescent materials. During preparation, raw materials often need to be ground to proper sizes. This enhances surface area and material activity. Ball mills refine powder through impact and grinding by media. They greatly reduce grinding time and boost production efficiency. This results in finer particle sizes and more uniform distribution. As a result, the luminescent performance of the materials is improved.

The sol-gel method

The sol-gel method forms a homogeneous solution by dissolving inorganic salts in water or alcohol solvents under proper pH. Through hydrolysis or alcoholysis and condensation, a polymer network sol is formed. This sol becomes a precursor for phosphor preparation. After calcination at high temperatures, the final product is obtained. This method for synthesizing rare earth phosphors has several advantages:

Small particle size, even reaching the nanoscale.

High reaction activity and low synthesis temperature.

Controllable particle size and uniform distribution.

Simple process with high product purity.

Excellent luminescent properties.

The solid-state method

The solid-state method is commonly used to prepare rare earth luminescent nanomaterials.

In the high-temperature solid-state method, solid materials are mixed evenly. Then the mixture is calcined in a high-temperature furnace to form the product. This method produces samples with few surface defects and good crystal quality.

The resulting materials have strong luminescence and are suitable for mass production. However, it also has drawbacks: high synthesis temperature, long sintering time, large particle size, uneven distribution, and lower luminescent efficiency.

The properties of rare earth materials depend on crystal structure and defects. Smaller rare earths reactant particles have larger surface areas. This increases contact area and promotes the solid-state reaction.

The spray pyrolysis method

The spray pyrolysis method involves mixing reaction materials with organic solvents like ethanol. Under appropriate pH conditions, a solution or colloid is formed. This is then added to a spray device to atomize the solution into an aerosol. The aerosol is sent into a high-temperature pyrolysis furnace, where thermal decomposition or combustion occurs. This method produces loose, spherical solid particles with small particle sizes. The particles have a uniform size distribution, high brightness, and excellent luminescent performance. However, this method has high energy consumption and low energy efficiency.

conclusion

In the future, rare earth luminescent materials will develop towards high performance, low cost, and environmental sustainability. Especially in areas such as white LED, full-spectrum lighting, medical diagnostics, and agricultural lighting, they have a broad market outlook. At the same time, policy support and technological innovation will further drive industry upgrades and deepen applications.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !