In modern materials science and industrial manufacturing, powder materials are widely used in electronics, ceramics, plastics, coatings, medicine, energy and other fields. According to the particle size and processing difficulty, powders are usually divided into four main categories: granules, fine powder, micro powder (also known as ultrafine powder), and nano powders. Powders of different particle sizes have significantly different properties and uses. Therefore, special equipment is required for precise preparation and control.

Granules

Granules refer to objects with a specific shape within a certain size range (generally from millimeters to nanometers). They can be solid particles or liquid forms such as droplets or oil droplets. Common dry granulation or granulation equipment, such as extrusion granulators, drum granulators, spray drying towers, etc. They can achieve uniform morphology control and strength adjustment, and are widely used in chemical, building materials, fertilizer and other industries.

Fine powder

Fine powder refers to powder that can pass through an 80-mesh sieve (180μm) and more than 95% can pass through a 100-mesh sieve (150μm). This type of powder is widely used in plastic fillers, cement additives, metal smelting and other fields. Its preparation mostly uses traditional grinding equipment such as Raymond mill, hammer crusher, impact mill, and ring roller mill. It has the advantages of large production capacity, low energy consumption, and mature structure.

Micro powder (ultrafine powder)

Micro powder usually refers to micron-grade materials with a particle size of less than 63μm. It requires a narrow particle size distribution and no impurity pollution. It is widely used in electronic ceramics, paints and coatings, high-end plastics, cosmetics and other fields. Its preparation mainly relies on equipment such as air jet mills, air classifier mills, vibration mills, and stirring mills. It is supplemented by high-efficiency air classifiers to achieve precise particle size control and meet the high requirements of the product for fineness and purity.

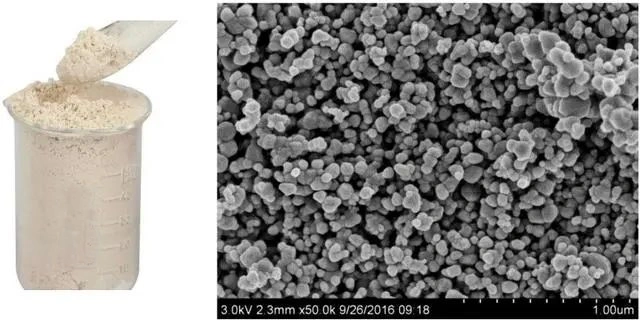

Nanopowder

Nanopowder, also known as nanoparticles, is generally ultrafine particles with a particle size between 1-100nm. It has special properties such as ultra-high specific surface area, surface energy, and quantum size effect. It has important application value in the fields of electronic packaging, photocatalysis, nano-coating, functional ceramics, biomedicine, etc. The preparation of nano-scale powders is difficult, and high-end equipment such as high-energy ball mills, plasma evaporation equipment, sol-gel devices, and gas phase synthesis devices are usually used. In order to avoid agglomeration and contamination, the equipment design must have characteristics such as closed systems, precise dispersion mechanisms, and no metal contact parts.

Equipment selection and technology integration

The degree of powder processing from granules to nanopowders has been gradually improved. The required equipment has also shifted from traditional mechanical to modern powder systems with high energy density, precision control and higher automation levels. At the same time, the combination of dry and wet processes and the integration of dispersion-grinding-classification have become the development trend of powder processing equipment. This is especially evident in the fields of functional materials such as silicon micropowder, alumina, calcium carbonate, and titanium dioxide.

conclusion

Powder particle size directly affects material performance. It also sets high demands on preparation processes and equipment. As powder processing equipment advances, materials move toward higher purity, finer size, and better functionality. With nanotechnology, new energy, and electronic packaging growing fast, powder equipment becomes more essential in the new materials industry.

epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing, grinding, classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !