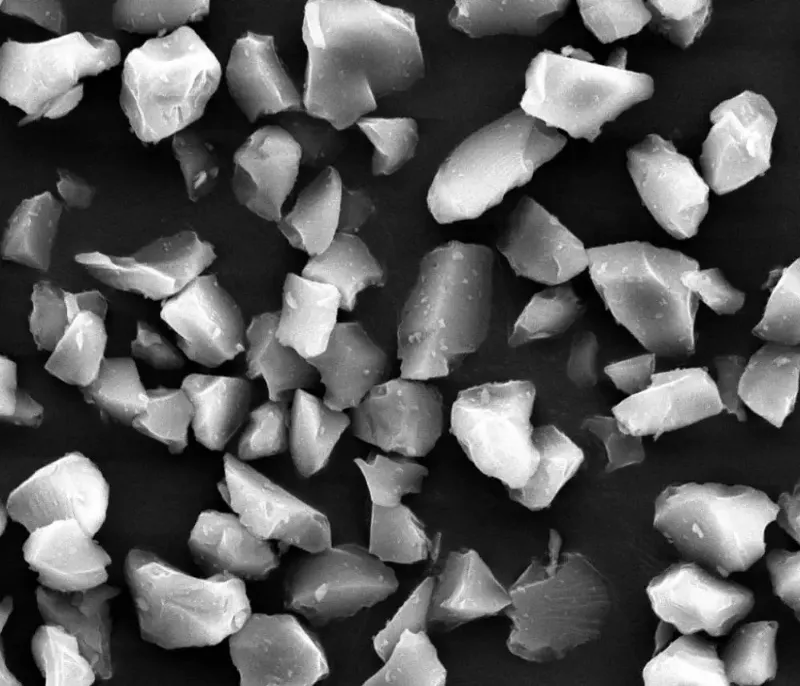

Silicon powder is made of crystalline quartz, fused quartz, etc., and is processed through grinding, precision classifying, impurity removal and other processes. According to the particle morphology, it can be divided into angular silica powder and spherical silica powder.

Angular silicon powder production process and equipment

Angular silicon powder is irregular in shape and mostly angular. Its production raw materials are mainly vein quartz, quartzite and fused quartz. It can be divided into crystalline silicon powder and fused silicon powder.

The main production equipment of angular silicon powder includes ball mill, classifier, mixer and coating machine, etc. The production process includes dry grinding and wet grinding.

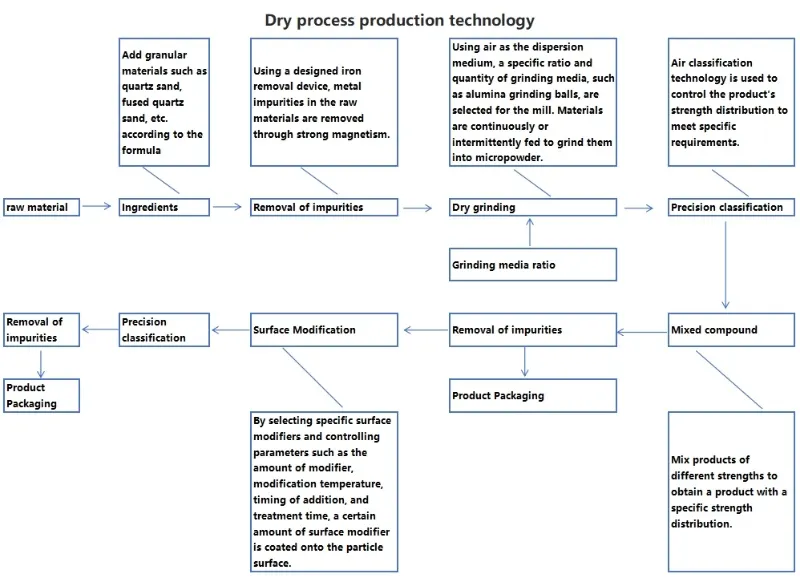

Dry process production technology and equipment

| Serial number | Process | Process content | Main equipment |

| 1 | Ingredients | Add materials such as quartz sand, fused quartz sand, etc. according to the formula. | —— |

| 2 | Impurity removal | Through the self-designed iron removal device, strong magnetism is used to remove the magnetically attracted metal foreign matter in the raw materials to obtain raw materials with higher purity. | Iron remover |

| 3 | Dry grinding | Using air as the dispersion medium, determine the specific ratio and quantity of grinding media such as alumina grinding balls for the mill, and continuously or intermittently add materials to grind the materials into micro powder. | Ball mill |

| 4 | Precision classification | Use airflow classification technology to control the particle size distribution of the product to meet specific needs. | Classifier |

| 5 | Mixing and compounding | Mix products of different particle sizes to obtain products with specific particle size distribution. | Mixer |

| 6 | Surface modification | Select a specific surface modifier, and by controlling the amount of surface modifier, modification temperature, addition time, processing time and other parameters, the surface of the product particles is coated with a certain amount of surface modifier. | Modifier |

| 7 | Product packaging | The product is weighed in the bag and the bag is sealed | Automatic packaging device |

The silicon micropowder raw material is placed into a ball mill or vibration mill for grinding. This grinding process can either be continuous, with materials fed in and discharged continuously, or involve batch feeding of a certain weight of raw material, followed by continuous grinding for a set period. During discharge, the particle size is controlled by a micropowder classifier. Coarse products are returned to the mill for regrinding or become the final product, while the finer ones are the product. For dry grinding, the moisture content of the material fed into the mill must be strictly controlled, as the product will not undergo further drying.

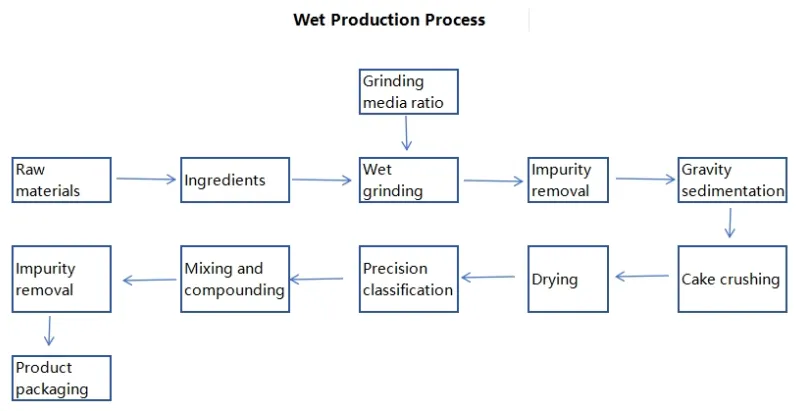

wet process production technology and equipment

A certain weight of silicon micropowder raw material is added to the ball mill. An appropriate amount of water is also added, with the operation concentration between 65% and 80%. After continuous grinding for several hours, the slurry is discharged. It is then dewatered using a filter press or allowed to naturally settle in a material barrel, forming a wet cake. The wet cake is crushed and dispersed. It is then evenly fed into a hollow shaft stirrer dryer. After drying, the final product is obtained.

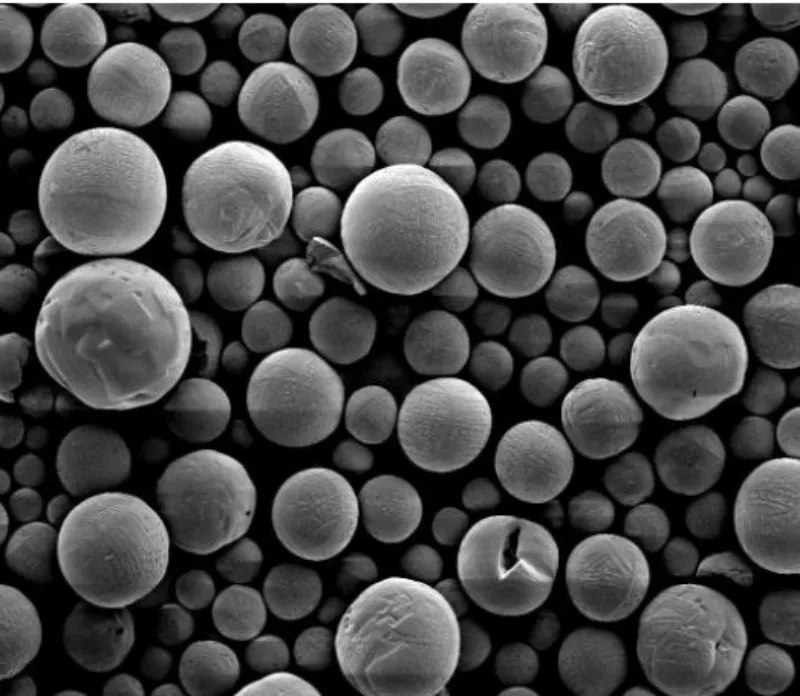

Spherical silicon powder production process and equipment

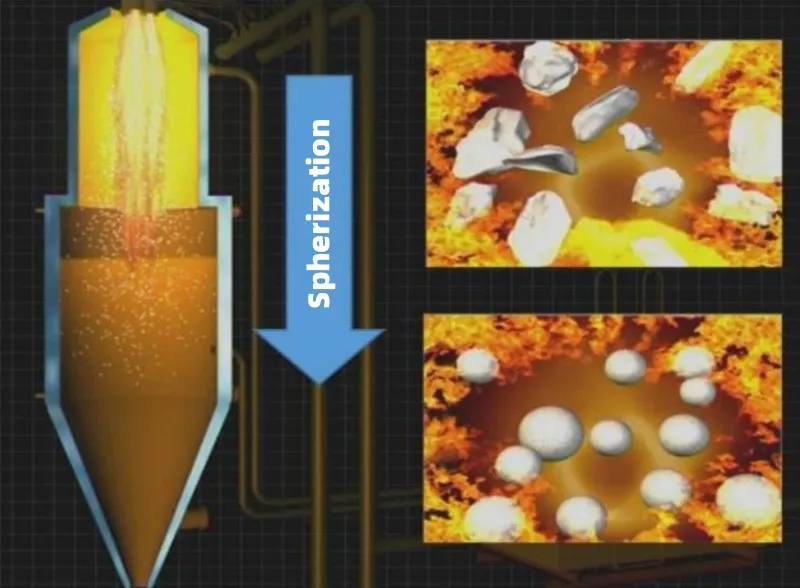

Spherical silicon micropowder refers to powder materials with individual particles that are spherical in shape. The main component is amorphous silica. The raw material for its production is primarily angular silicon micropowder. The main production methods include flame fusion, plasma heating furnace, chemical synthesis, and hydrolysis.

Comparison of various spherical silicon powder production methods

| Physical method | Process flow | Characteristics |

| Flame spheronization method | Send silicon micropowder into the high temperature field generated by gas-oxygen. Melt at high temperature and cool into balls to form high-purity spherical silicon micropowder | Easy to achieve industrialized large-scale production |

| High temperature melt spraying method | Melting high-purity quartz into quartz liquid at 2100-2500°C. After spraying and cooling, spherical silicon micropowder is obtained | The spherical rate and amorphous rate are both close to 100% But it is difficult |

| Plasma method | Using the high temperature area of plasma to melt silicon dioxide powder. Spherical droplets are formed due to the surface tension of the liquid, and spherical particles are formed during the rapid cooling process | High energy, fast heat transfer, fast cooling, the resulting product morphology is controllable, high purity, no agglomeration |

The principle and process of producing spherical silicon micropowder by high-frequency plasma melting are similar to the flame fusion method. The difference is the use of a plasma generator as the heat source. The temperature range is moderate, control is stable, and the output is high. This method allows for higher sphericity, making it a suitable production method.

The hydrolysis method involves adding liquid SiCl₄ at a constant speed into deionized water with different dispersants. A quartz rod is used to rapidly stir the water-soluble product. The hydrolysis product is aged, washed, and filtered. It is then dried at 100°C-200°C in a constant temperature chamber until it reaches a constant weight. After drying, the product is transferred to a high-temperature sintering furnace. Here, it undergoes dehydration and phase transformation at different temperatures. The final product is ground and sieved to obtain high-purity spherical silicon micropowder with the desired particle size.

epic powder

In conclusion, Epic Powder offers advanced solutions for the production of both angular and spherical silicon micropowder. With a focus on precision grinding, classification, and surface modification, our state-of-the-art equipment ensures high-purity and consistent products tailored to various industrial needs.