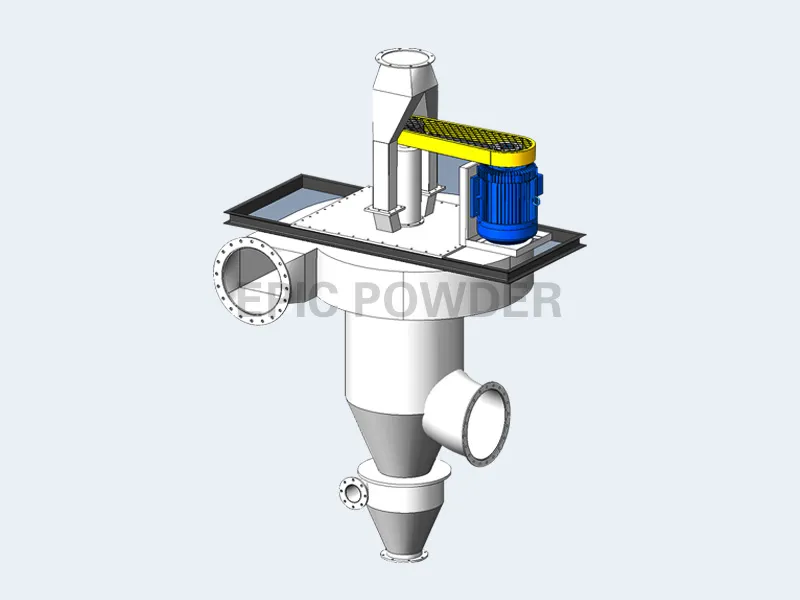

Air Separator

- High fines yield and maximum fines capacity, with a single classifier wheel

- Superfine powders in the range of d97 = 3 µm to d97 = 45 µm

- Classifying wheel supported in bearings on both sides

- Double flooded fine material outlet

- Optimized feed material supply direct to the classifier wheel

- Compact and functional design

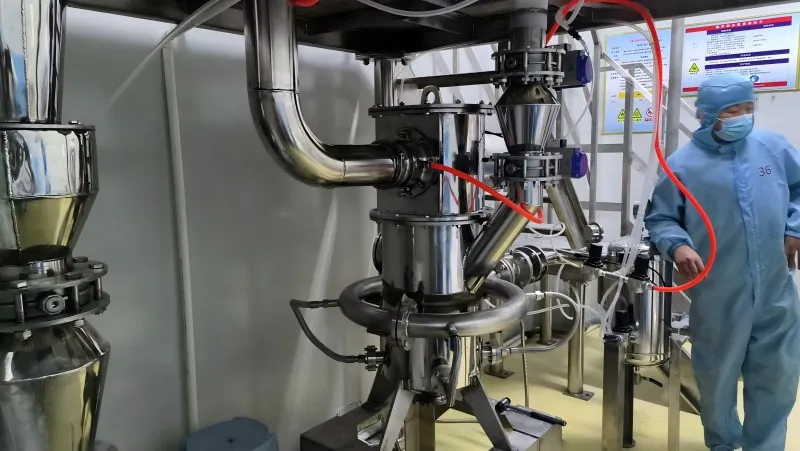

Working Principle

The feeding port of the classifier is at the top of the classifier. The feed enters the classifier from the top inlet under the action of gravity, and then falls onto the centrifugal dispersion disc of the classifying wheel. The material will be evenly dispersed, dispersed to the baffle ring and down into the grading area. Classification air enters the scroll housing, passes the guide vanes, and inwards to the classification wheel. The fine powder is carried by the airflow into the classifying wheel, and then enters the cyclone collector or dust collector with the airflow, while the coarse powder will be repelled by the centrifugal force of the classifying wheel and fall into the lower body of the classifier.

Features And Benefits

- The hierarchical structure design is unique, low pressure, low energy consumption.

- It is very good for apex cutting of ultra-fine products and medium-fine products.

- Applicable to a wide range of particle sizes, the coarsest can reach 200 microns.

- There are different models to meet different output, and the feeding capacity of the largest model can reach 800t/h.

- Wear-resistant design, can handle powder products with extremely high hardness.

- The design of internal air circulation can reduce investment and save floor space.

- It can be combined with a ball mill to form a closed-circuit production system for grinding various materials.

Technical Parameters

Related Products

Project Cases

Related Posts

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA