Classifying & Separating

Classification are based on the effects of centrifugal force, gravity, inertial force, etc., of different sizes powders in the medium (usually air) to form different trajectories, so as to realize the separation of different sizes powders.

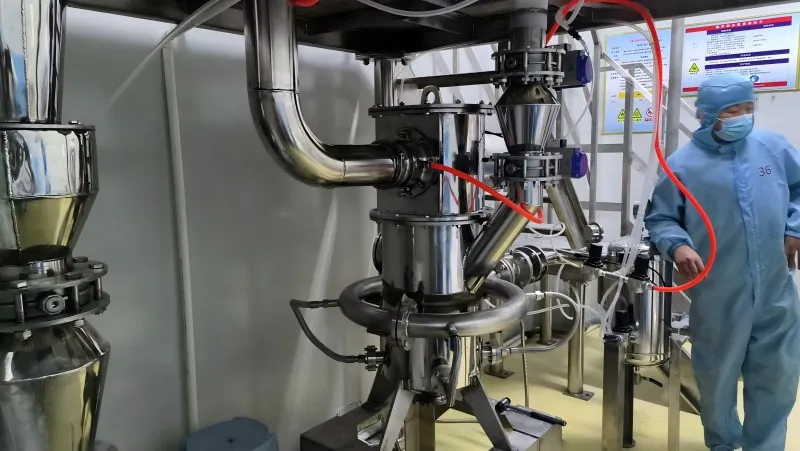

Material would go from the bottom part of air classifier up to the classifying chamber by the air flow from suction fan. The classifier wheel with high-speed rotation would create a strong centrifugal force to separate coarse and fine powder. Qualified fine powder would go through the wheel vane then into the cyclone or bag filter, while coarse entraining fine powder would lose its speed and fall down along the wall of chamber to the inlet of secondary air. The secondary air flow would disperse it further and separate coarse and fine powder. Fine powder would go up to the classifying chamber for further classifying, while coarse powder would fall down and will be discharged from the bottom outlet.

Advantages of EPIC Powder Classifying

High classifying efficiency

Classifying efficiency (extraction ratio) can be 90%.

Flexible adjustment of particle size

Speed of wheel is controlled by inverter; particle size can be adjusted freely.

Ceramic materials is available

No metal pollution, high-purity product.

High classifying efficiency

Classifying efficiency (extraction ratio) can be 90%.

Flexible adjustment of particle size

Speed of wheel is controlled by inverter; particle size can be adjusted freely.

Ceramic materials is available

No metal pollution, high-purity product.

4 types of ultrafine powder classifiers

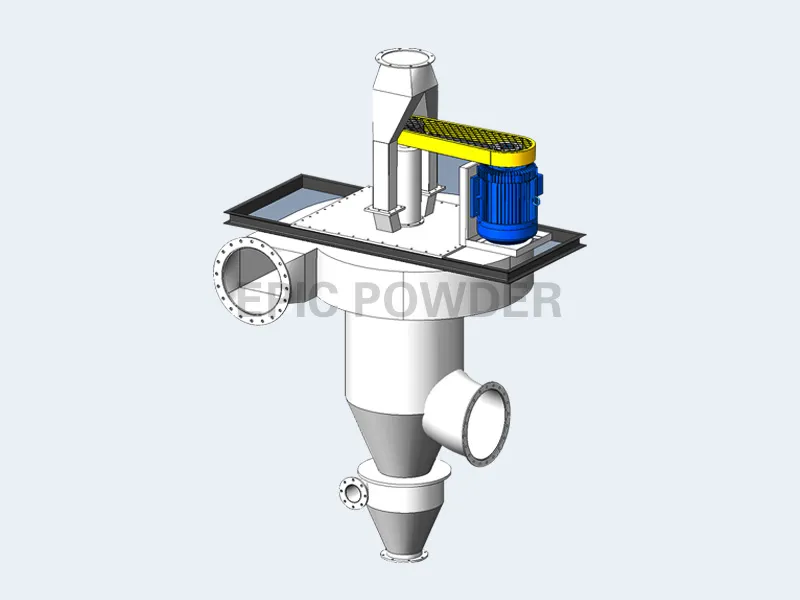

Air Classifier

Air classifier is ideal for fine powders of ceramics, abrasives, glass, minerals, and polymers.Superfine powders in the range of d97 = 8 µm to d97 = 45 µm.

Centrifugal Classifier

CTC series air classifier is designed under the guidance of our German experts, and it is specially developed for separating powder products between 32-250μm.

Air Separator

MBS series air classifier is jointly designed by our German experts and British experts, and is specially used for efficient dry classification of D97: 8-200 micron powder.

Turbo-Double Classifier

High fines yield and maximum fines capacity, with a single classifier wheel. Superfine powders in the range of d97 = 3 µm to d97 = 45 µm.

Industry we serve

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA