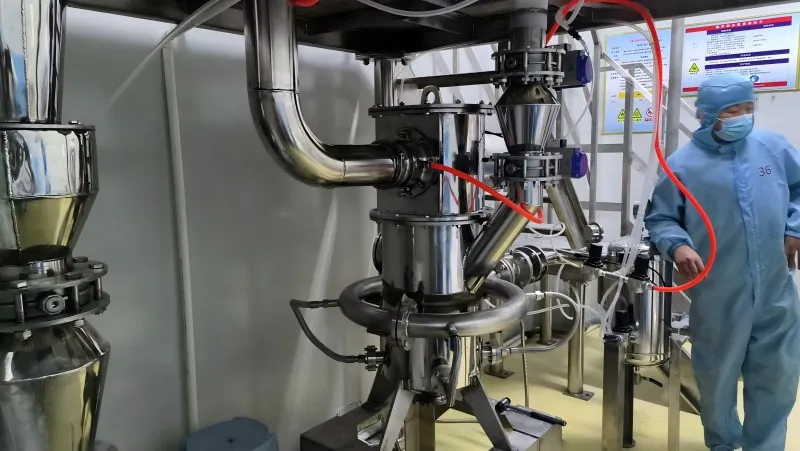

In the pharmaceutical industry, ultrafine pulverization generally has the following characteristics

- Small particle size, concentrated and uniform distribution, saving raw materials;

- Adiabatic expansion of low-temperature and high-pressure air will absorb the heat generated by the collision of materials, will not overheat locally, and retain the biologically active ingredients of the drug, which is conducive to making the required high-quality products;

- Simple quick disassembly and assembly structure, which is conducive to cleaning and replacing material varieties.

Generally, the size of the particles is about 100 microns, and they are ultra-finely pulverized to several microns. After ultra-micro processing, the surface area of the particles increases, and their dispersibility, adsorption capacity, surface activity, etc. have comprehensive changes. It is of great significance for improving the efficacy and saving the dosage.

Project Cases

12/02/2026

With the rise of the circular economy, a biomass materials company in Turkey sought to transform waste coffee grounds into high-value industrial raw materials. Post-drying, ...

Read More →

15/01/2026

Project Background A well-known graphite supplier in the United States aimed to expand its production capacity for lithium battery anode materials. The core requirement of ...

Read More →

08/01/2026

Customer BackgroundThe customer is a leading Australian supplier of advanced ceramics and thermal conductivity materials. Alumina Ultrafine Grinding is critical for this application, as the ...

Read More →

29/12/2025

A well-known Belgian manufacturer of specialty engineering plastics focuses on the R&D and production of high-performance polymers. One of its core products, polyether ether ketone ...

Read More →

Related Posts

11/02/2026

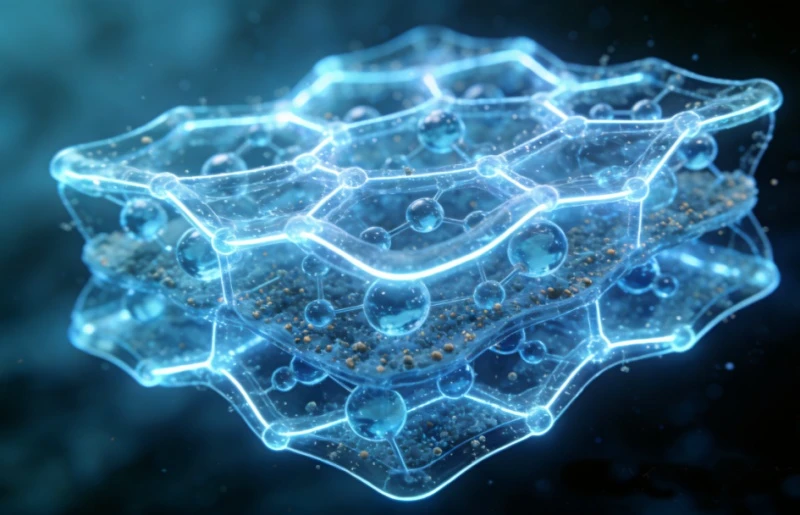

Sodium iron phosphate (NaFePO4) is a promising cathode material widely used in sodium-ion batteries. Known for its excellent thermal stability, environmental friendliness, and cost-effectiveness, sodium ...

Read More →

06/02/2026

Core Advantages: Why Sodium Wins on the Balance Sheet – Cost Structure Economics Sodium-ion batteries (SIBs) offer a compelling cost advantage that directly improves the ...

Read More →

04/02/2026

In lithium-ion battery production, the anode ultrafine milling process is a critical step, particularly for natural or artificial graphite anodes (and increasingly for silicon-based or ...

Read More →

30/01/2026

Have you ever wondered why premium paints don’t drip when applied to walls? Why high-quality toothpaste holds its shape firmly on the brush without collapsing? ...

Read More →

28/01/2026

I. Introduction: The “Purity War” in Semiconductor Materials Defining the 5N Standard: Why 99.999% Purity Matters In the semiconductor industry, purity is paramount. The “5N” ...

Read More →

23/01/2026

Achieving perfect particle size in superfine alumina grinding is a technical challenge that demands precision beyond raw power. When targeting a steep particle size distribution ...

Read More →

We can provide processes and equipment that meet the following performance indicators

Jet Mill

Suitable for grinding materials with high hardness, high purity and high added value.

Air Classifying Mill

Integration of grinding and classifying

Spiral Jet Mill

On-line cleaning (CIP) and on-line sterilization(SIP)design is optional.

- Full ceramic protection, increased amount of metal <20ppb.

- The physical shape of the particles is stable, the particle size is uniform, and has good dispersibility, and does not cause agglomeration or precipitation.

- Simple quick disassembly and assembly structure, which is conducive to cleaning and replacing materials.

- Low residue, low pollution, less impurities.

- Jet mill can be used instead of impact mill for production, with higher safety and finer particle size.

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA