Mineral

There are more than 3000 kinds of minerals currently known in nature, and more than 200 kinds of common minerals. Among them, silicate minerals account for about 90% of the earth’s crust. Other important mineral groups include natural elements, sulfides, oxides, halides, carbonates, sulfates and phosphates.

Minerals are widely used in industry. Salt, borate, barite, quartz sand, gypsum, etc. are widely used as raw materials in the chemical industry; limestone and fluorite are used as combustion aids in steelmaking; graphite, magnesite, foundry sand and refractory clay are used in metallurgy; Phosphates, nitrates and potash are essential in fertilizer manufacturing; various other industrial minerals are used in ceramics, grinding, oil well drilling, mud, filtration, etc.

In polymer materials such as plastic, rubber, adhesives and composites used in non-metal powder filler, such as calcium carbonate, kaolin, talc, silica, wollastonite, asbestos, magnesium hydroxide and aluminum hydroxide, etc., The surface of the filler must be modified to enhance its compatibility with the matrix, dispersibility, mechanical strength and comprehensive performance.

“Green and high value” is the principle that EPIC follows in industrial mineral processing. In the long-term practice, EPIC has accumulated rich experience and can provide a full set of production technology and processing machine for minerals.

Project Cases

Related Posts

We can provide processes and equipment that meet the following performance indicators

Jet Mill

Suitable for grinding materials with high hardness, high purity and high added value.

Air Classifying Mill

Integration of grinding and classifying

Spiral Jet Mill

On-line cleaning (CIP) and on-line sterilization(SIP)design is optional.

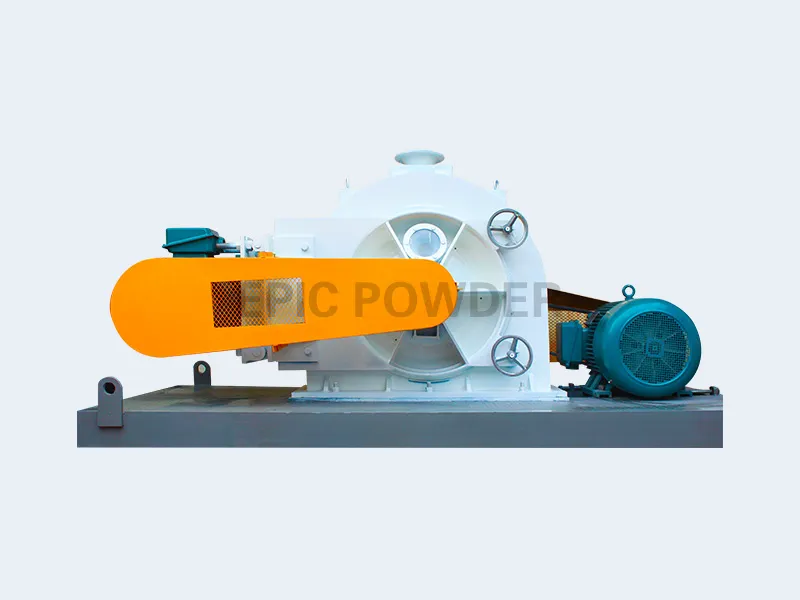

Pin Mill

The material should not exceed Mohs hardness 3.

Rotor Mill for drying, dispersing and modifying

Realize the functions of drying, dispersing and modifying at the same time

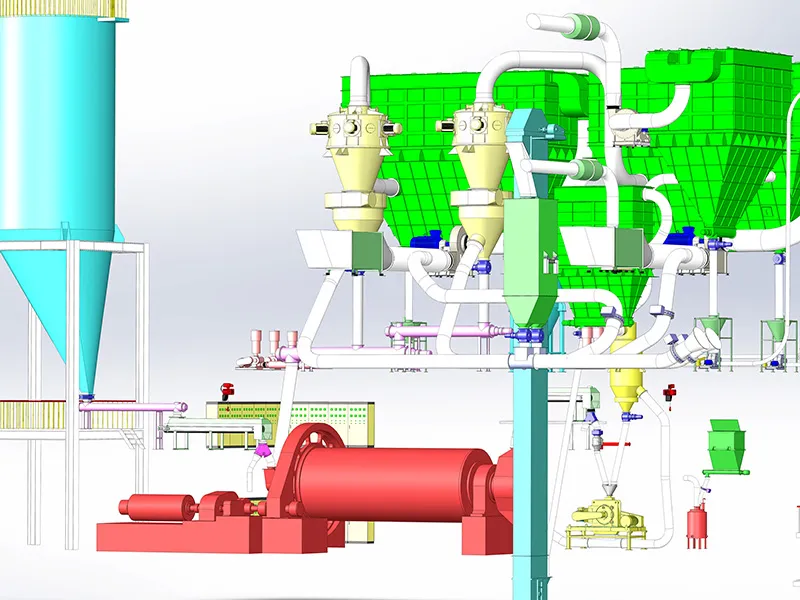

Ball Mill and Air Classifier Production Line

Cooperate with the classifier to produce products of multiple particle sizes at the same time

- High produce collection efficiency 99.9%.

- The key parts in contact with the materials are protected by a variety of materials to ensure the purity of the materials to a greater extent.

- Grinding is in closed system, little dust, low noise in a clean and environmentally friendly process.

- It can realize the functions of drying, dispersing and modification at the same time.

- According to material hardness, added value, output, etc., choose a better solution.

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA