Fertilizer

Chemical fertilizers refer to fertilizers produced by chemical methods or mining minerals, and are also called inorganic fertilizers, including nitrogen fertilizers, phosphate fertilizers, potash fertilizers, micro-fertilizers, compound fertilizers, etc. They have the following common characteristics: simple composition, high nutrient content; fast fertilizer effect and strong fertilizer; some fertilizers have acid-base reaction; generally they do not contain organic matter and have no effect on improving soil fertility.

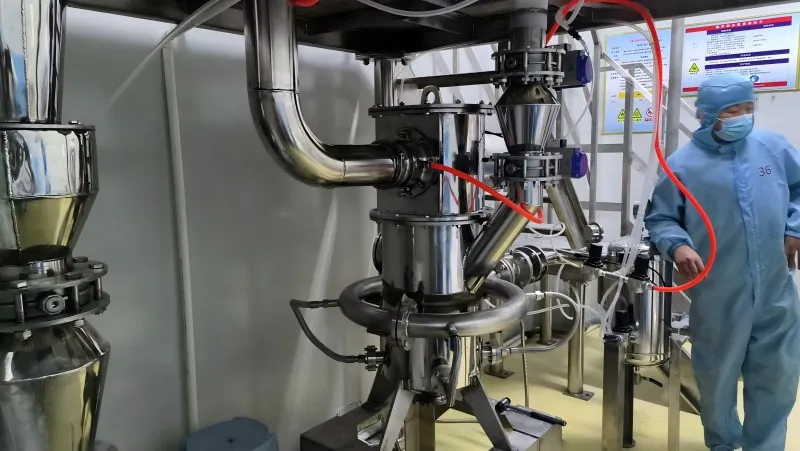

Chemical fertilizer is a compound mixture made from various raw materials after reasonable adjustment and processing. After the ultrafine treatment, the surface area of the particles is increased, and their dispersibility, adsorption capacity, surface activity, etc. have comprehensive changes, which are of great significance for improving fertilizer efficiency and saving dosage.

Project Cases

Related Posts

We can provide processes and equipment that meet the following performance indicators

Jet Mill

Suitable for grinding materials with high hardness, high purity and high added value.

Air Classifying Mill

Integration of grinding and classifying

- According to the material risk and explosion-proof level, the integrated safety and fire control measures such as explosion release, explosion isolation and explosion suppression are adopted to ensure the safety and control of the production operation process.

- According to the temperature requirements of the material production process, air cooling, water cooling, liquid nitrogen and other targeted temperature control measures are adopted to keep the material at an appropriate temperature during the production process.

- Adopting air or inert gas circulation closed circulation process design to effectively control the intake of external moisture.

- The key parts in contact with the materials are protected by a variety of materials to ensure the purity of the materials to a greater extent.

- The integrated solution of drying and grinding can shorten the process flow, save workshop space, and greatly reduce unit energy consumption and machine investment.

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA