Animal Feed

The grinding of feed ingredients is a very important part of feed processing. The grinding can increase the total surface area of the raw material particles per unit mass, increase the solubility of feed nutrients in the animal digestive juice, and improve the digestibility; at the same time, the particle size of the crushed raw materials is important for subsequent processes (Such as granulation, etc.) the degree of difficulty and the quality of the finished product have a very important impact.

The size of the crushing particle size directly affects the production cost. When producing powdered compound feed, the power consumption of the crushing process is about 50% to 70% of the total power consumption. The smaller the pulverized particle size, the better for animal digestion and absorption, and the better for granulation, but at the same time the power consumption will increase accordingly, and vice versa. Properly mastering the crushing technology and selecting the appropriate crushing models are issues that cannot be ignored in feed production.

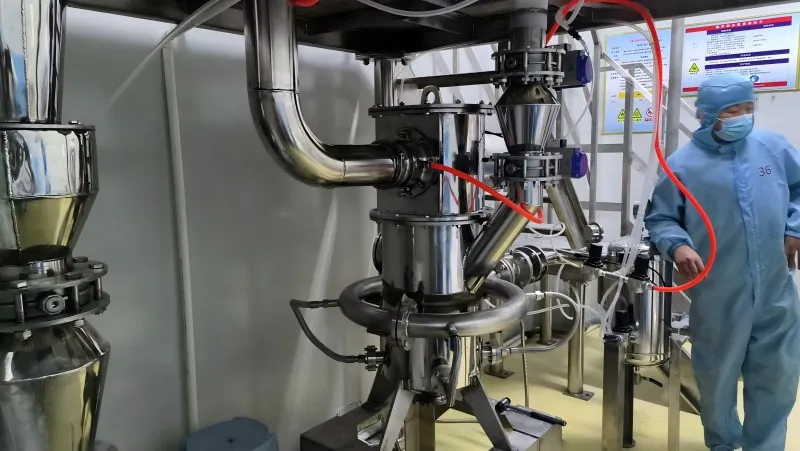

Project Cases

Related Posts

We can provide processes and equipment that meet the following performance indicators

Jet Mill

Suitable for grinding materials with high hardness, high purity and high added value.

Air Classifying Mill

Integration of grinding and classifying

Rotor Mill for drying, dispersing and modifying

Realize the functions of drying, dispersing and modifying at the same time

- Low failure rate and stable operation

Suitable for continuous operation, with an annual operating time of more than 8000 hours.

- Large air volume intake design

The grinding temperature can be reduced. If there is a higher temperature requirement, a cold air device can be selected.

- Clean and environmentally friendly

The whole system is closed, with less dust, low noise, and the production process is clean and environmentally friendly.

- Easy to disassemble and clean

Compact structure, easy to remove and wash mills and fans. Optional online cleaning to prevent material sticking and reduce downtime.

- Integrated design of grinding and classification

Achieve the desired product size by adjusting the classifier wheel speed.

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA