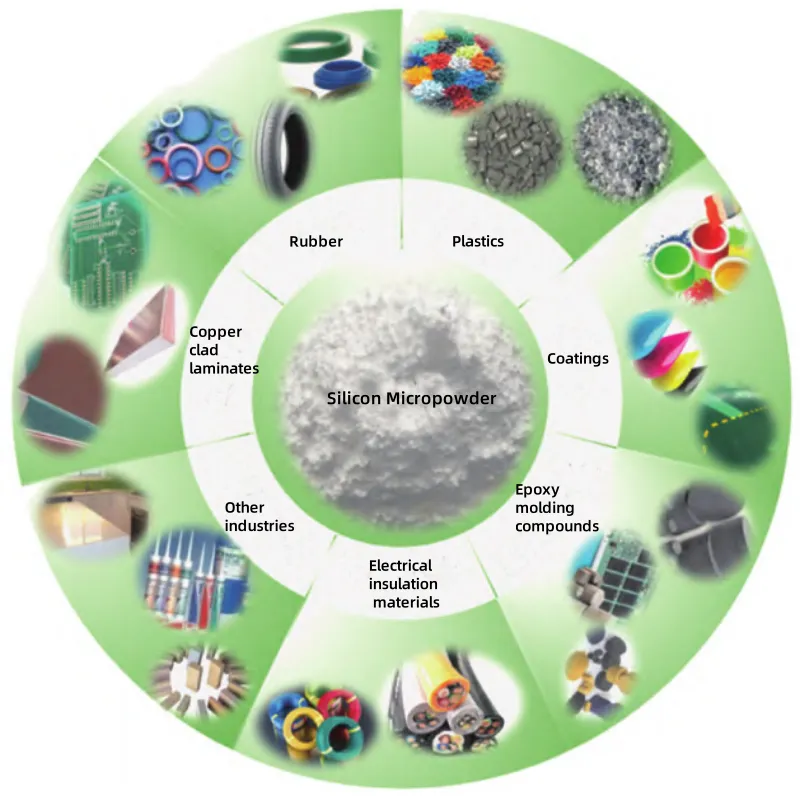

Silicon micropowder, a high-performance inorganic non-metallic functional material, is widely used in various fields, such as copper-clad laminates, epoxy encapsulants, coatings, paints, rubber, ceramics, cosmetics, pharmaceuticals delivery, and catalysis. With continuous advancements in technology and growing demand from downstream industries, the quality requirements for silicon micropowder are increasing.

Trends in Silicon Micropowder Demand: Precision

Silicon micropowder is mainly produced from natural quartz or fused silica, through a series of fine processing methods including crushing, classification, grinding, magnetic separation, flotation, and acid washing. As high-tech industries like electronics, 5G, semiconductors, and photovoltaics rapidly develop, the demand for

quartz powder is growing.

High-purity ultrafine silicon micropowder has small particle sizes, large specific surface areas, high chemical purity, and excellent filler properties. It shows excellent stability, reinforcing capability, and thixotropy, which can significantly enhance material mechanical performance. Therefore, ultrafining and high-purification of silicon micropowder is a current industry development trend. In particular, as electronic products become thinner and lighter, the demand for increasingly ultrafine quartz powder as filler in copper-clad laminates is rising.

Ultrafine Grinding Technology

Ultrafine powders can be prepared by chemical synthesis or physical grinding methods. Chemical methods have low yield and complex processes, while physical grinding methods are cost-effective, simple, and suitable for large-scale industrial production. Grinding methods can be divided into dry and wet processes.

Dry processing generally follows the steps of: feeding → grinding → classification → collection → packaging. Wet processing includes: feeding → grinding → drying → depolymerization → classification → collection → packaging. The dry process is simpler and more cost-effective, which is why most silicon micropowder manufacturers adopt it. Wet processing is more complex and expensive, but it is suitable for ultrafine products with particle sizes under 5 microns that require surface treatment.

Recent advances in ultrafine grinding technology for quartz powder include mechanical grinding, air jet grinding, wet milling, and ultrasonic grinding.

Ultrafine Grinding Equipment

Common ultrafine grinding equipment includes air jet mills, stirred mills, vibration mills, and planetary ball mills.

Fluidized Bed Opposed Air Jet Mill: After the compressed air is filtered and dried, it is sprayed into the grinding chamber at high speed through the Laval nozzle. At the intersection of multiple high-pressure airflows, the materials are repeatedly collided, rubbed, and sheared to be crushed.

Stirred mills use a stirrer to agitate grinding media, applying impact, shear, and friction to the material. This is suitable for high-hardness materials and can effectively improve the fineness and dispersion of quartz powder. Vibration mills are more suitable for brittle materials. They effectively improve the purity and activity of quartz powder. This process also reduces defects and impurities. Planetary ball mills use planetary motion. This creates multi-dimensional motion between grinding media and materials. It achieves ultrafine grinding, making it ideal for high-purity and high-fineness silicon micropowder.

On the other hand, for ultrafine products, the smaller the particle size, the more difficult it becomes to remove magnetic impurities. As the particle size decreases, it becomes harder to absorb magnetic impurities. The key to controlling impurities in ultrafine silicon micropowder is ensuring low-impurity raw materials, preventing contamination from the production environment, and enhancing impurity removal during the process.

Due to the high hardness and toughness of quartz, traditional mechanical grinding faces challenges such as high energy consumption, low capacity, and potential contamination. In contrast, air jet grinding technology has become an ideal choice for producing high-purity silicon micropowder. This technology uses high-speed air currents to make material particles collide, producing silicon micropowder with uniform particle size distribution and high purity. Air jet grinding enhances the dispersion and reactivity of silicon micropowder, making it ideal for producing high-purity silicon micropowder for electronic packaging.

Epic powder

In the future, continuous innovation and optimization of ultrafine grinding technologies will expand their application in silicon micropowder production. The key breakthrough for producing high-purity ultrafine quartz powder lies in developing grinding equipment and processes. These processes must prevent impurity introduction and avoid secondary contamination.

Epic Powder specializes in designing and producing advanced grinding and classification equipment. Our equipment includes jet mills, stirred mills, and planetary ball mills. Our cutting-edge technology ensures efficient, high-purity processing of materials like silicon micropowder. We optimize processes to meet the high demands of industries like electronics, photovoltaic, and semiconductors. Through continuous innovation and attention to detail, Epic Powder leads in providing tailored ultrafine grinding solutions for high-performance materials.