What are the key equipment and challenges in Diatomaceous Earth Ultrafine Grinding?

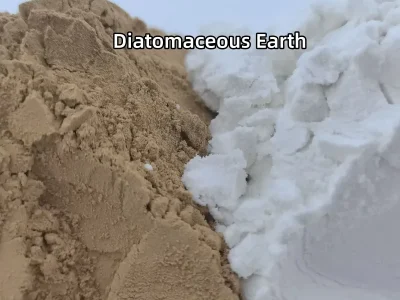

Diatomaceous Earth (DE), also known as diatomite or diatom mud, is a porous, lightweight, silica-rich sedimentary rock formed from the fossilized remains of ancient diatoms. […]

What are the key equipment and challenges in Diatomaceous Earth Ultrafine Grinding? Read More »