Activated carbon is a carbon material with high specific surface area, high porosity and high adsorption performance. It is usually obtained by high-temperature carbonization and activation of carbon raw materials. Depending on the raw materials, activated carbon can be divided into wood charcoal, coal-based activated charcoal and synthetic activated carbon.

Activated carbon application areas

Based on physical and chemical properties, activated carbon is widely used in various fields. These include industry, agriculture, defense, transportation, medicine, and environmental protection. Its demand has been increasing annually with social development and improved living standards. Especially in recent years, growing environmental protection requirements have significantly raised global demand.

Environmental protection

Activated carbon can be used to treat waste gas and wastewater generated during steelmaking. By adding activated charcoal to the wastewater treatment pool, pollutants can be adsorbed and treated with activated sludge. This process helps reduce pollutant content and improves wastewater treatment efficiency.

Water treatment field

Activated charcoal can effectively adsorb various organic compounds, heavy metal ions, microbes, and odors from water. It improves water quality and taste. Especially in emergencies, coal-based activated charcoal quickly adsorbs toxic substances, ensuring public safety.

Food and Beverage Industry

Activated carbon can be used to remove impurities, odors, and pigments, preserving the original flavor and color of food and beverages. Additionally, it has good moisture absorption and adsorption properties, helping with storage and preservation of food and drinks.

Agriculture

Activated carbon can be used as a fertilizer additive to improve crops’ resistance to stress and pests. It also enhances soil structure, improving water retention and nutrient-holding capacity.

Other fields

Activated carbon has a wide range of applications in other fields as well. It can be used as a catalyst and catalyst carrier in industries like chemicals, pharmaceuticals, and metallurgy. Additionally, activated charcoal is used in textiles, dyeing, and leather industries to improve product quality and performance.

Activated carbon preparation process

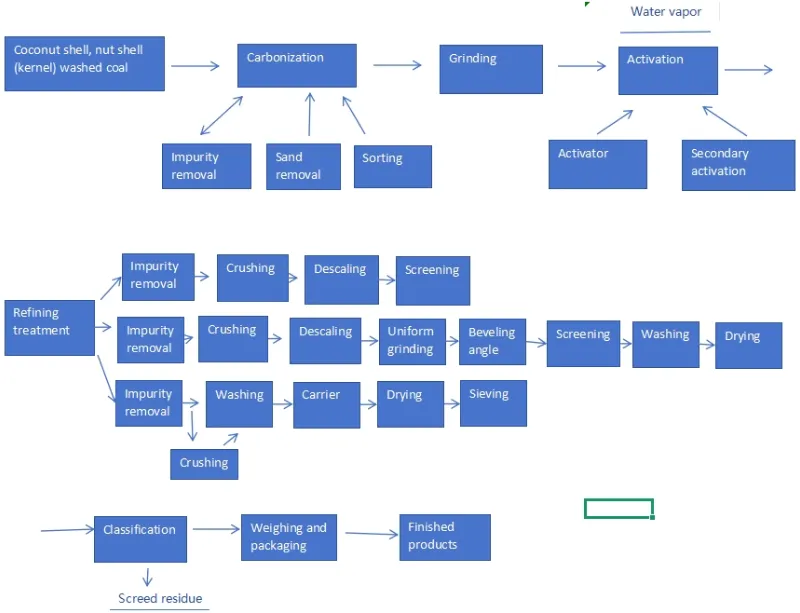

Coal-based activated carbon preparation process

Raw Material Preparation:

Select suitable coal, and perform pre-treatment processes such as crushing, grinding, drying, and screening.

Carbonization:

Heat the coal raw material to a high temperature under oxygen-limited conditions, causing pyrolysis to generate carbon and collect volatile components.

Activation:

React the carbonized material with a gaseous activating agent at high temperature to enhance its surface area and pore structure.

Post-treatment:

React the carbonized material with a gaseous activating agent at high temperature to further improve its surface area and pore structure.

Wood activated carbon preparation process

In the production of activated charcoal, the raw materials need to be processed to a certain fineness to ensure the activity of the final product. This is a critical step in the entire production process.

conclusion

In conclusion, activated charcoal powder grinding technology plays a crucial role in enhancing the performance and efficiency of activated charcoal production. By ensuring the right particle size and consistency, this technology directly influences the surface area and adsorption capacity of the final product. As demand for activated carbon continues to grow across various industries, advancements in grinding technology will remain key to optimizing production processes, improving product quality, and meeting increasingly stringent environmental standards.

epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !