উপাদানের মধ্যে বিভিন্ন পরিবর্তন ঘটে যায় নাকাল প্রক্রিয়া। মোটা গ্রাইন্ডিংয়ে এই পরিবর্তনগুলি সামান্য হলেও অতি সূক্ষ্ম গ্রাইন্ডিংয়ে তাৎপর্যপূর্ণ, কারণ উচ্চ গ্রাইন্ডিং তীব্রতা, দীর্ঘ গ্রাইন্ডিং সময় এবং উপাদানের বৈশিষ্ট্যে উল্লেখযোগ্য পরিবর্তন ঘটে। অতি সূক্ষ্ম গ্রাইন্ডিংয়ের সময় যান্ত্রিক প্রভাবের কারণে সৃষ্ট এই ঘটনাটি উপাদানের স্ফটিক গঠন এবং ভৌত রাসায়নিক বৈশিষ্ট্যে পরিবর্তন আনে। একে গ্রাইন্ডিং প্রক্রিয়ার যান্ত্রিক রাসায়নিক প্রভাব বলা হয়।

কণার আকার পরিবর্তন

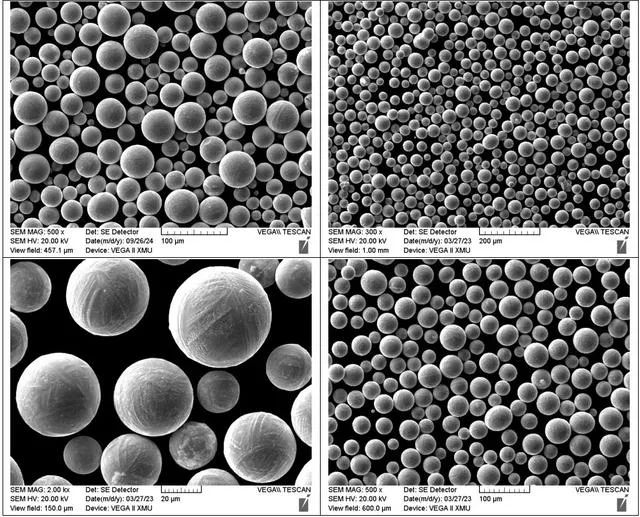

সবচেয়ে স্পষ্ট পরিবর্তন পাউডার উপকরণ অতি সূক্ষ্ম গ্রাইন্ডিংয়ের পরে কণার আকার হ্রাস পায়। কণার আকারের উপর নির্ভর করে, অতি সূক্ষ্ম পাউডারগুলিকে সাধারণত ভাগ করা হয়:

- মাইক্রন স্কেল (১–৩০ মাইক্রোমিটার)

- সাবমাইক্রন স্কেল (০.১–১ মাইক্রোমিটার)

- ন্যানোমিটার স্কেল (০.০০১–০.১ মাইক্রোমিটার)

স্ফটিক গঠন পরিবর্তন

অতি সূক্ষ্ম গ্রাইন্ডিংয়ে, তীব্র এবং দীর্ঘস্থায়ী যান্ত্রিক বল বিভিন্ন মাত্রার জালি বিকৃতি ঘটায়। শস্যের আকার হ্রাস পায়, কাঠামো বিশৃঙ্খল হয়ে যায় এবং পৃষ্ঠে একটি নিরাকার বা অ-স্ফটিক পর্যায় তৈরি হয়। এমনকি পলিক্রিস্টালাইন রূপান্তর ঘটতে পারে। এক্স-রে বিবর্তন, ইনফ্রারেড স্পেকট্রোস্কোপি, নিউক্লিয়ার ম্যাগনেটিক রেজোন্যান্স, ইলেকট্রন প্যারাম্যাগনেটিক রেজোন্যান্স এবং ডিফারেনশিয়াল থার্মাল বিশ্লেষণের মতো কৌশল ব্যবহার করে এই পরিবর্তনগুলি সনাক্ত করা যেতে পারে।

উদাহরণস্বরূপ:

- কোয়ার্টজ: কোয়ার্টজ স্ফটিক গঠন এবং রাসায়নিক গঠনের দিক থেকে এটি সবচেয়ে সহজ সিলিকেট খনিজগুলির মধ্যে একটি। যান্ত্রিক শক্তি দ্বারা সৃষ্ট যান্ত্রিক রাসায়নিক ঘটনার জন্য এটি প্রথম খনিজগুলির মধ্যে একটি। গবেষণায় দেখা গেছে যে যখন কোয়ার্টজকে একটি কম্পন মিল ব্যবহার করে পিষে ফেলা হয়, তখন প্রাথমিক পর্যায়ে শস্যের আকার হ্রাস পায়। তবে, দীর্ঘ সময় ধরে পিষে ফেলার পরে, মূল পরিবর্তন হল জমাটবদ্ধকরণ এবং পুনঃক্রিস্টালাইজেশনের কারণে অ্যামোরফাইজেশন। পিষে ফেলার সময় অ্যামোরফস স্তর তৈরির পরে পাতলা ক্ষারীয় দ্রবণ বা জলে কোয়ার্টজের দ্রবণীয়তা বৃদ্ধি পায়।

- কাওলিন: অতি সূক্ষ্ম গ্রাইন্ডিংয়ের সময় যান্ত্রিক সক্রিয়তার কারণে কেওলিন, মাইকা, ট্যালক, বেন্টোনাইট এবং ইলাইটের মতো স্তরযুক্ত সিলিকেট খনিজগুলি তাদের ক্রমযুক্ত স্ফটিক কাঠামো হারায় এবং নিরাকার হয়ে যায়। অ্যামোরফাইজেশন সাধারণত হাইড্রোক্সিল গ্রুপের ক্ষতি এবং এই খনিজগুলিতে বন্ধন শক্তি হ্রাসের সাথে সম্পর্কিত।

- ক্যালসাইট: পলিক্রিস্টালাইন রূপান্তর হল যান্ত্রিক শক্তি দ্বারা সৃষ্ট একটি কাঠামোগত পরিবর্তন যা পদার্থের রাসায়নিক গঠন পরিবর্তন করে না। পলিক্রিস্টালাইন রূপান্তরের দুটি রূপ রয়েছে:

- দ্বি-পর্যায়ের রূপান্তর, সাধারণত বিপরীতমুখী এবং এন্ডোথার্মিক।

- একক-পর্যায়ের রূপান্তর, বেশিরভাগই অপরিবর্তনীয় এবং বহির্মুখী।

গ্রাইন্ডিংয়ের সময় ক্যালসাইট রম্বিক অ্যারাগোনাইটে রূপান্তরিত হয়। ঘরের তাপমাত্রা এবং চাপে এই রূপান্তরটি বিপরীতমুখী। দীর্ঘক্ষণ গ্রাইন্ডিংয়ের পরে, ক্যালসাইট এবং অ্যারাগোনাইটের অনুপাত প্রায় সমান হয়ে যায়।

- অ্যালুমিনা মাইক্রো পাউডার: গ্রাইন্ডিং সময় বেশি হলে, উচ্চ-বিশুদ্ধতা অ্যালুমিনার স্ফটিক শস্যের আকার হ্রাস পায়, অন্যদিকে ল্যাটিস স্ট্রেন এবং কার্যকর ডেবাই প্যারামিটার বৃদ্ধি পায়।

রাসায়নিক গঠন পরিবর্তন

শক্তিশালী যান্ত্রিক সক্রিয়তার কারণে, কিছু পদার্থ অতি সূক্ষ্মভাবে পিষে ফেলার সময় সরাসরি রাসায়নিক বিক্রিয়ার মধ্য দিয়ে যায়। এই বিক্রিয়ার মধ্যে রয়েছে পচন, গ্যাস-কঠিন, তরল-কঠিন এবং কঠিন-কঠিন বিক্রিয়ার।

উদাহরণস্বরূপ:

- ভ্যাকুয়াম মিলে ক্যালসাইট, ম্যাগনেসাইট, লোহা ডলোমাইট, ফেল্ডস্পার এবং লোহা স্পিনেল পিষে নেওয়ার সময়, CO₂ নির্গত হয়।

- ক্ষারীয় ধাতু, ক্ষারীয় মাটির ধাতু এবং নিকেল, তামা, ম্যাঙ্গানিজ, দস্তা ইত্যাদির কার্বনেটগুলি পিষে ফেলার সময় পচে যায়।

- একটি ভাইব্রেশন বল মিলে গ্রাইন্ডিংয়ের সময় জিঙ্ক অক্সাইড এবং অ্যালুমিনা বিক্রিয়া করে স্পিনেল এবং নিরাকার জিঙ্ক অক্সাইড পাউডার তৈরি করে।

দ্রাব্যতা পরিবর্তন

যখন কোয়ার্টজ, ক্যালসাইট, ক্যাসিটারাইট, কোরান্ডাম, বক্সাইট, ক্রোমাইট, ম্যাগনেটাইট, গ্যালেনা, টাইটানোম্যাগনেটাইট, আগ্নেয়গিরির ছাই এবং কাওলিনের মতো পদার্থগুলিতে সূক্ষ্ম গ্রাইন্ডিং বা অতি সূক্ষ্ম গ্রাইন্ডিং প্রয়োগ করা হয়, তখন অজৈব অ্যাসিডে তাদের দ্রবীভূতির হার এবং দ্রাব্যতা বৃদ্ধি পায়।

সিন্টারিং বৈশিষ্ট্যের পরিবর্তন

সূক্ষ্ম বা অতিসূক্ষ্ম গ্রাইন্ডিংয়ের কারণে তাপীয় বৈশিষ্ট্যের পরিবর্তনের মধ্যে প্রধানত অন্তর্ভুক্ত:

- উন্নত বিচ্ছুরণের সাথে, কঠিন-পর্যায় বিক্রিয়াগুলি সহজ হয়ে যায়, সিন্টারিং তাপমাত্রা হ্রাস করে এবং পণ্যগুলির যান্ত্রিক বৈশিষ্ট্যগুলিকে উন্নত করে।

- উদাহরণস্বরূপ, একটি ভাইব্রেশন মিলে ডলোমাইটকে সূক্ষ্মভাবে পিষে ফেলার পর, অবাধ্য পদার্থের সিন্টারিং তাপমাত্রা 375–573K কমে যায় এবং উপাদানের যান্ত্রিক বৈশিষ্ট্য উন্নত হয়।

- কোয়ার্টজ এবং ফেল্ডস্পার অতি সূক্ষ্মভাবে গ্রাইন্ড করার পর, এনামেলের সিন্টারিং সময় কমানো হয়েছিল এবং সিরামিক পণ্যের শক্তি উন্নত হয়েছিল।

- স্ফটিকের গঠন পরিবর্তন এবং রূপ পরিবর্তন, পর্যায় পরিবর্তনের তাপমাত্রা।

- উদাহরণস্বরূপ, অতি সূক্ষ্ম গ্রাইন্ডিংয়ের কারণে α-কোয়ার্টজ থেকে β-কোয়ার্টজ এবং কোয়ার্টজ থেকে ক্রিস্টোবালাইটে রূপান্তর তাপমাত্রা পরিবর্তিত হয়।

ক্যাশন এক্সচেঞ্জ ক্যাপাসিটি পরিবর্তন

কিছু সিলিকেট খনিজ, বিশেষ করে বেন্টোনাইট এবং কাওলিনের মতো কাদামাটি খনিজ, সূক্ষ্ম বা অতি-সূক্ষ্ম গ্রাইন্ডিংয়ের পরে ক্যাটেশন বিনিময় ক্ষমতায় উল্লেখযোগ্য পরিবর্তন দেখায়।

- উদাহরণস্বরূপ, গ্রাইন্ডিং সময় বাড়ার সাথে সাথে, বেন্টোনাইটের ক্যাটেশন বিনিময় ক্ষমতা প্রথমে বৃদ্ধি পায় এবং পরে হ্রাস পায়। গ্রাইন্ডিং সময় বেশি হওয়ার সাথে সাথে ক্যালসিয়াম আয়ন বিনিময় ক্ষমতা ক্রমাগত হ্রাস পায়।

- একটি নির্দিষ্ট সময়ের জন্য গ্রাইন্ডিংয়ের পর, কাওলিনের ক্যাটেশন বিনিময় ক্ষমতা এবং বিনিময়যোগ্যতা বৃদ্ধি পায়, যা বিনিময়যোগ্য ক্যাটেশনের বৃদ্ধি নির্দেশ করে।

হাইড্রেশন বৈশিষ্ট্য এবং প্রতিক্রিয়াশীলতার পরিবর্তন

সূক্ষ্মভাবে পিষে ফেলা ক্যালসিয়াম হাইড্রোক্সাইডের মতো পদার্থের প্রতিক্রিয়াশীলতা বাড়াতে পারে, যা নির্মাণ সামগ্রী তৈরির জন্য গুরুত্বপূর্ণ। কিছু উপকরণ জলবিদ্যুৎ বিক্রিয়ার ক্ষেত্রে নিষ্ক্রিয় বা অপর্যাপ্তভাবে সক্রিয় থাকে।

- উদাহরণস্বরূপ, আগ্নেয়গিরির ছাইয়ের হাইড্রেশন কার্যকলাপ এবং ক্যালসিয়াম হাইড্রোক্সাইডের সাথে এর প্রতিক্রিয়া প্রাথমিকভাবে প্রায় শূন্য ছিল, কিন্তু একটি বল মিল বা ভাইব্রেশন মিলে সূক্ষ্মভাবে পিষে ফেলার পরে, কার্যকলাপটি ডায়াটোমাসিয়াস পৃথিবীর কাছাকাছি স্তরে বৃদ্ধি পায়।

- সূক্ষ্মভাবে গ্রাইন্ডিং ব্লাস্ট ফার্নেস স্ল্যাগের হাইড্রেশন কর্মক্ষমতা উল্লেখযোগ্যভাবে উন্নত করতে পারে। অতএব, উচ্চ শক্তি এবং উচ্চ স্ল্যাগ সামগ্রী সহ সিমেন্ট উৎপাদন সম্ভব। সিমেন্ট শিল্প এবং পরিবেশ সুরক্ষার জন্য এর তাৎপর্য অত্যন্ত গুরুত্বপূর্ণ।

বৈদ্যুতিক বৈশিষ্ট্য পরিবর্তন

সূক্ষ্ম বা অতি সূক্ষ্ম গ্রাইন্ডিং খনিজ পদার্থের পৃষ্ঠের বৈদ্যুতিক বৈশিষ্ট্য এবং ডাইইলেক্ট্রিক কর্মক্ষমতাকেও প্রভাবিত করে। উদাহরণস্বরূপ, প্রভাব ক্রাশিং এবং গ্রাইন্ডিংয়ের পরে বায়োটাইটের আইসোইলেকট্রিক বিন্দু এবং পৃষ্ঠের জিটা সম্ভাবনা পরিবর্তিত হয়।

ঘনত্বের পরিবর্তন

প্ল্যানেটারি বল মিল ব্যবহার করে প্রাকৃতিক এবং সিন্থেটিক জিওলাইট পিষে নেওয়ার গবেষণায় ঘনত্বের বিভিন্ন পরিবর্তন দেখা গেছে।

- প্রাকৃতিক জিওলাইটের ক্ষেত্রে, ঘনত্ব প্রাথমিকভাবে হ্রাস পায় এবং ১২০ মিনিট ধরে নাকাল করার পর তার সর্বনিম্ন মান পৌঁছায়। দীর্ঘক্ষণ নাকাল করার পর, ঘনত্ব কিছুটা বৃদ্ধি পায় কিন্তু মূল উপাদানের তুলনায় কম থাকে।

- ঘনত্ব হ্রাসের অল্প সময়ের পরে, সিন্থেটিক জিওলাইট গ্রাইন্ডিং সময় অব্যাহত থাকার সাথে সাথে ঘনত্ব বৃদ্ধি দেখায়। 240 মিনিট গ্রাইন্ডিংয়ের পরে, নমুনার ঘনত্ব মাটির বাইরে থাকা উপাদানের ঘনত্বকে ছাড়িয়ে যায়।

ক্লে সাসপেনশন এবং হাইড্রোজেলের বৈশিষ্ট্য

ভেজা পিষে মাটির প্লাস্টিকতা এবং শুষ্ক বাঁকানোর শক্তি বৃদ্ধি করতে পারে। বিপরীতে, শুকনো পিষে মাটির প্লাস্টিকতা এবং শুষ্ক বাঁকানোর শক্তি অল্প সময়ের মধ্যে বৃদ্ধি পায়, কিন্তু দীর্ঘক্ষণ পিষে এই বৈশিষ্ট্যগুলি হ্রাস পায়।

উপসংহারে, উপকরণের যান্ত্রিক রাসায়নিক পরিবর্তনগুলিকে প্রভাবিত করার কারণগুলির মধ্যে রয়েছে কাঁচামালের বৈশিষ্ট্য, ফিডের আকার, গ্রাইন্ডিং বা সক্রিয়করণের সময়, সরঞ্জামের ধরণ, গ্রাইন্ডিং পদ্ধতি, গ্রাইন্ডিং পরিবেশ এবং সংযোজন। যান্ত্রিক রাসায়নিক প্রভাব অধ্যয়ন করার সময়, এই কারণগুলির ব্যাপক প্রভাব বিবেচনা করা উচিত।

এপিক পাউডার

এপিক পাউডার, আল্ট্রাফাইন পাউডার শিল্পে ২০+ বছরের কাজের অভিজ্ঞতা। আল্ট্রাফাইন পাউডারের ক্রাশিং, গ্রাইন্ডিং, শ্রেণীবিভাগ এবং পরিবর্তন প্রক্রিয়ার উপর মনোযোগ দিয়ে, আল্ট্রাফাইন পাউডারের ভবিষ্যত উন্নয়নে সক্রিয়ভাবে প্রচার করুন। বিনামূল্যে পরামর্শ এবং কাস্টমাইজড সমাধানের জন্য আমাদের সাথে যোগাযোগ করুন! আমাদের বিশেষজ্ঞ দল আপনার পাউডার প্রক্রিয়াকরণের মূল্য সর্বাধিক করার জন্য উচ্চমানের পণ্য এবং পরিষেবা প্রদানের জন্য নিবেদিতপ্রাণ। এপিক পাউডার—আপনার বিশ্বস্ত পাউডার প্রক্রিয়াকরণ বিশেষজ্ঞ!